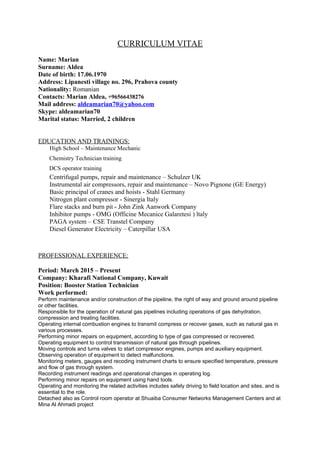

Marian Aldea has over 25 years of experience as a field operator and technician in oil and gas facilities in Romania and Kuwait. He has extensive experience operating and maintaining pipelines, compressors, pumps, boilers and other equipment. Aldea is proficient in DCS systems from Siemens and Delta-V and speaks English at a medium level. He has qualifications in chemistry, mechanics, compressor and pump repair, and hazardous waste treatment processes.