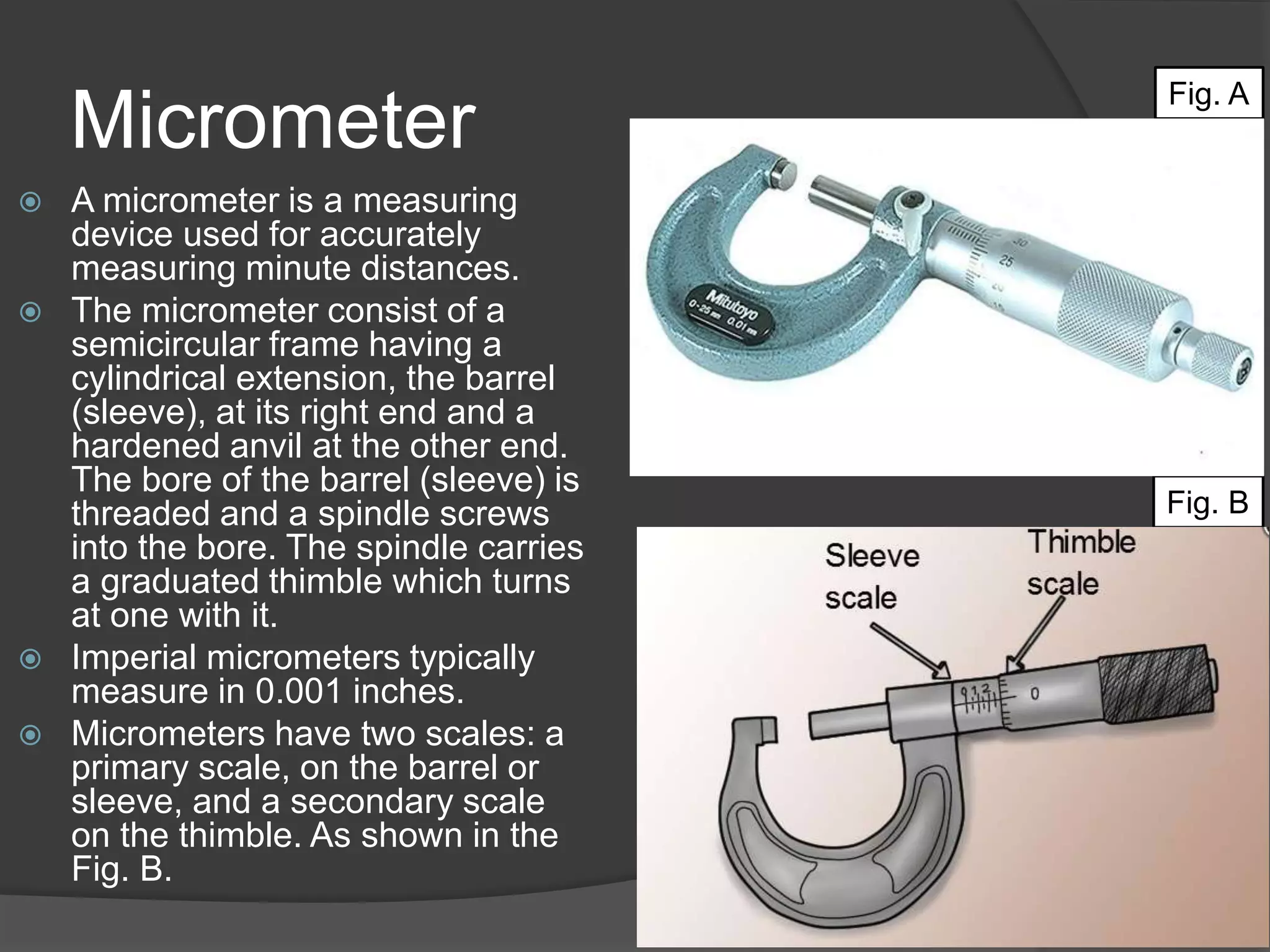

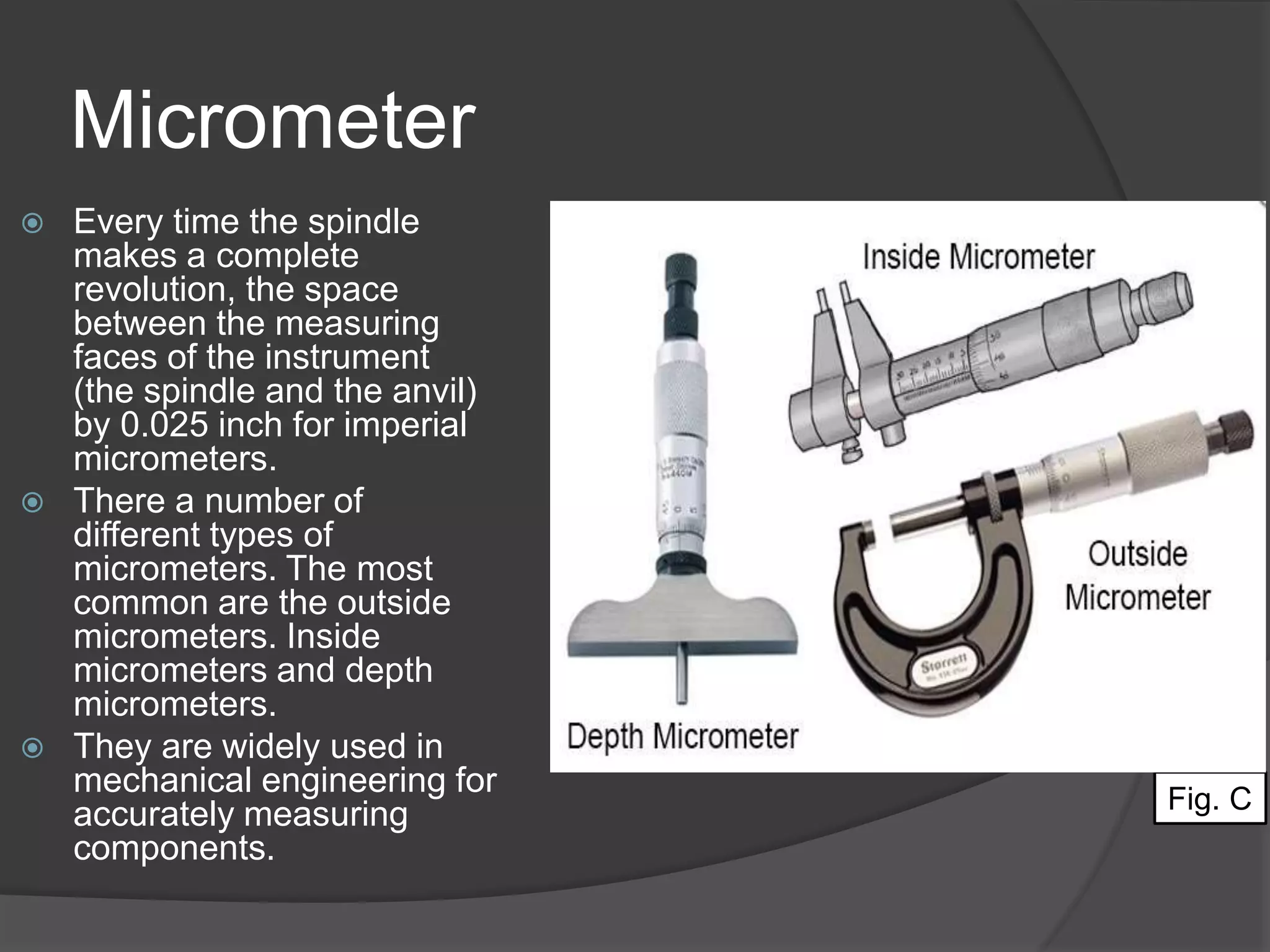

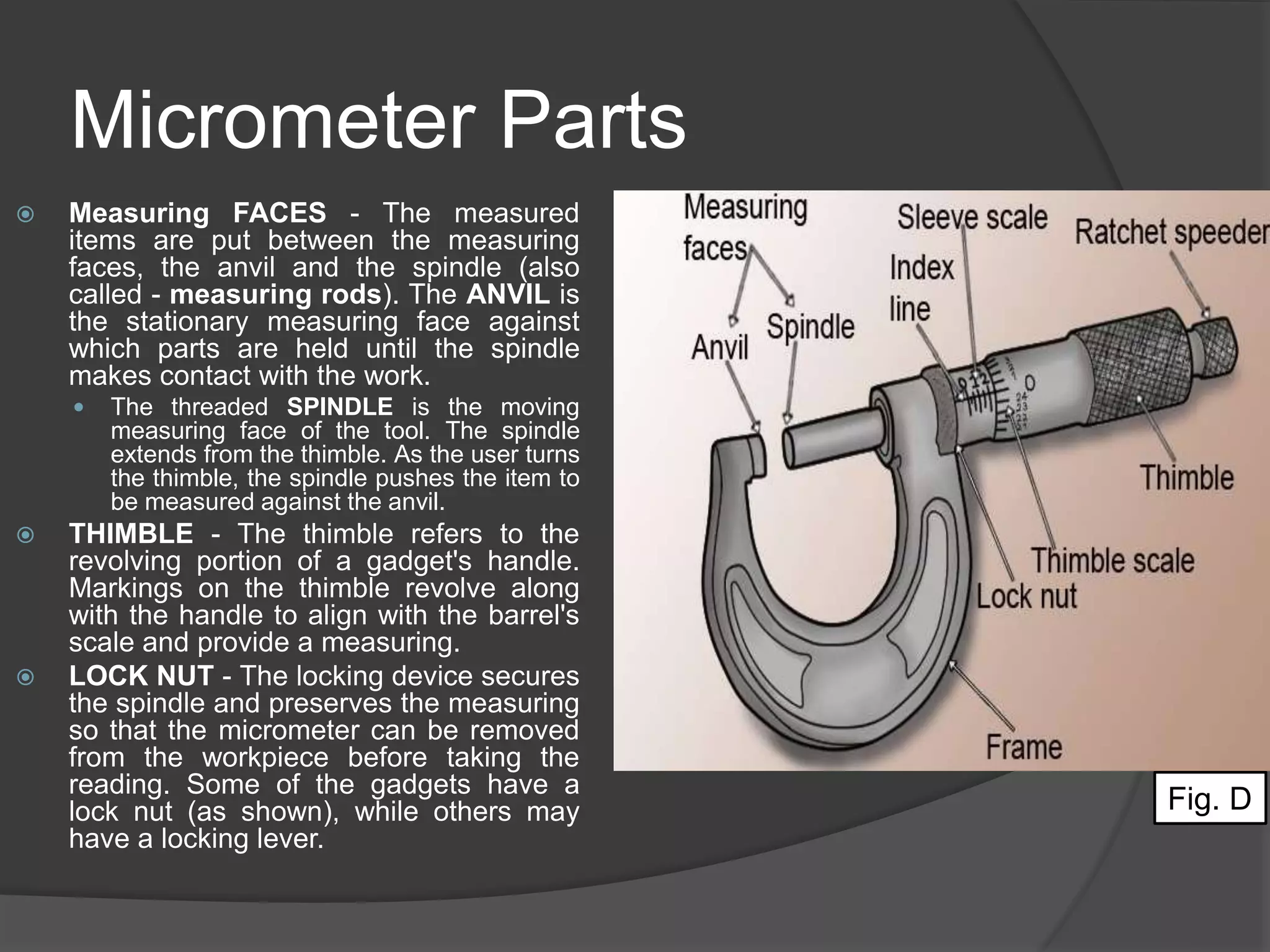

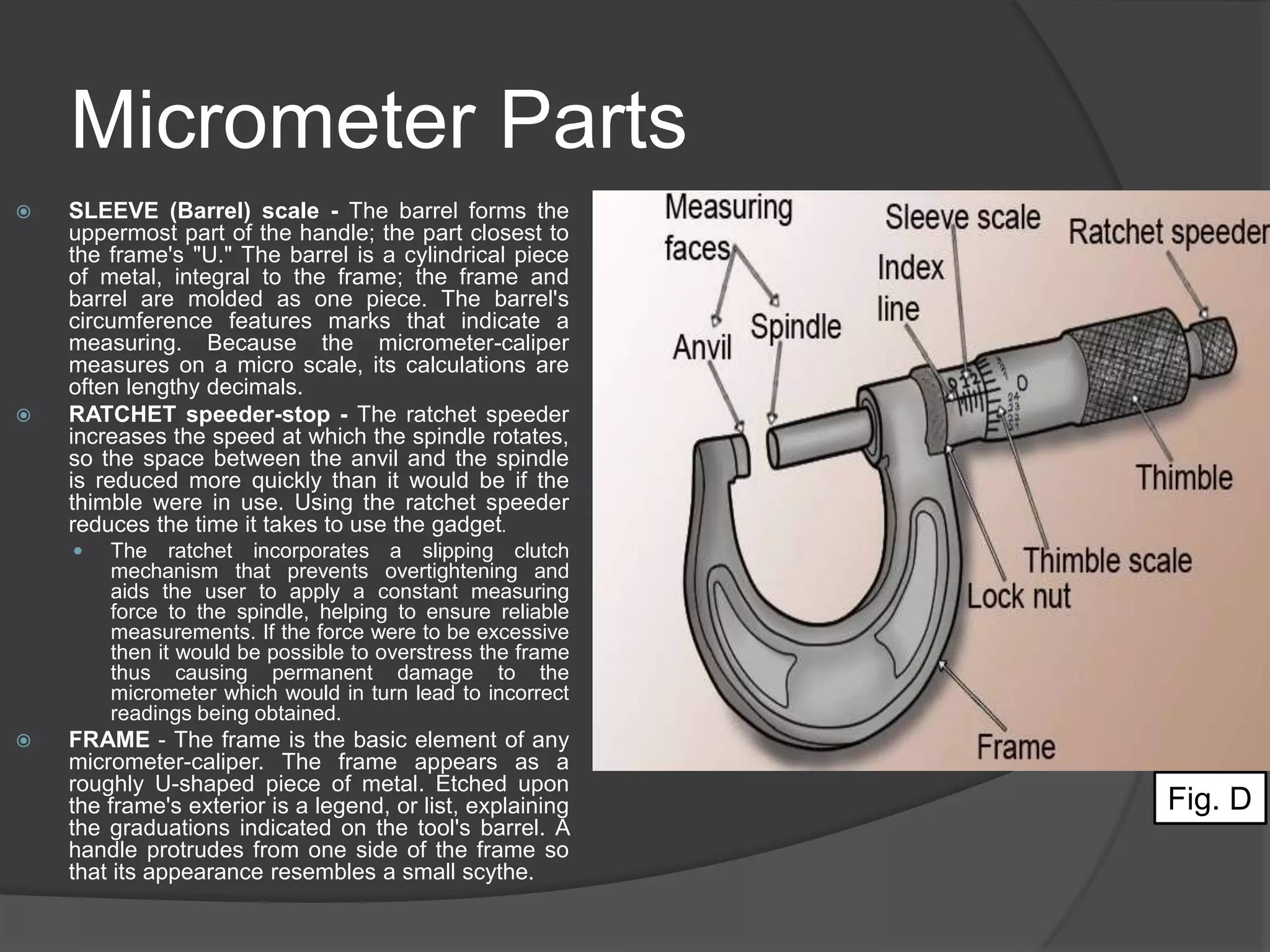

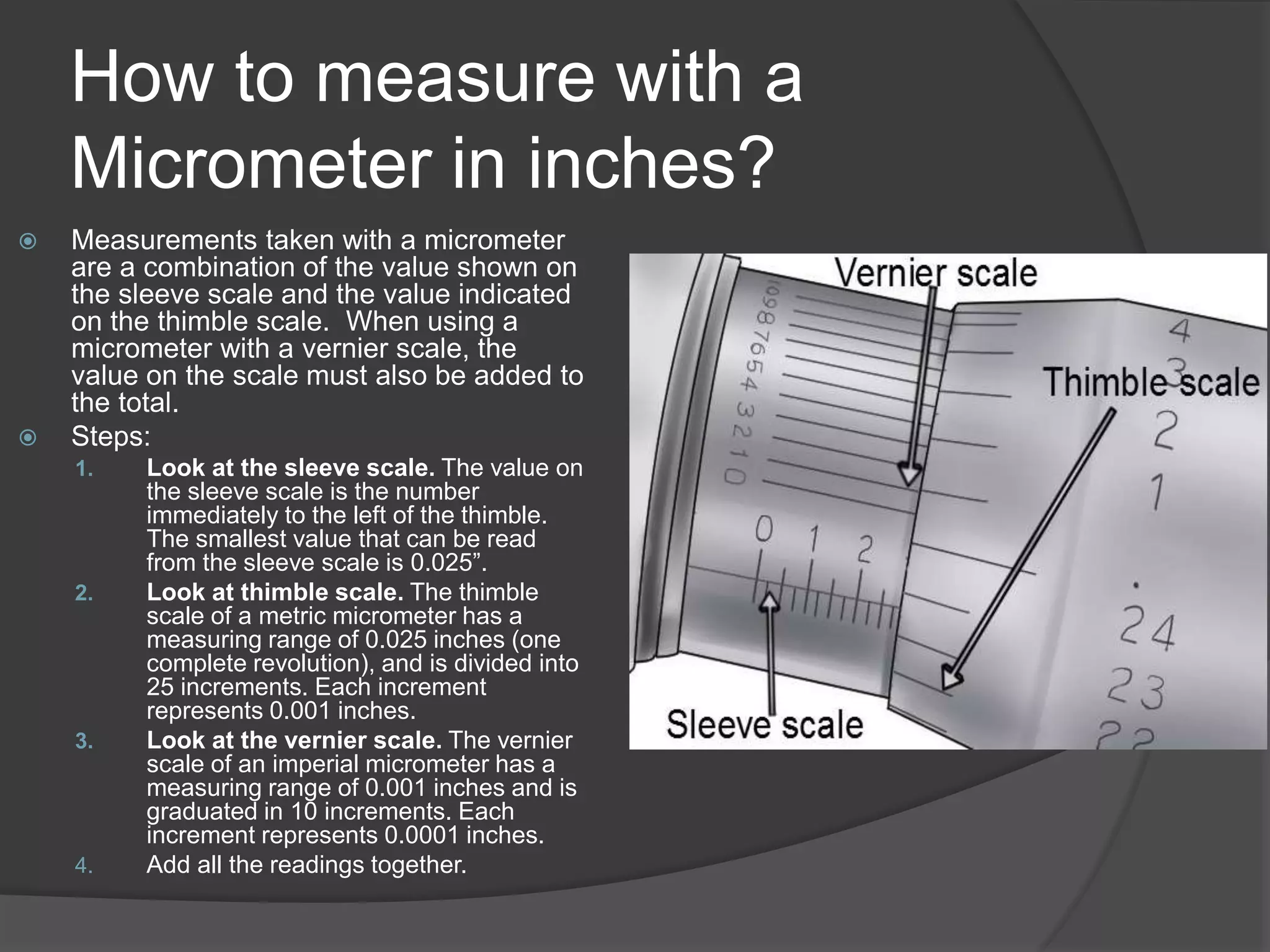

This document provides an overview of how to use a micrometer to take measurements. It defines the key parts of a micrometer, including the thimble, sleeve, anvil and spindle. The document explains that micrometers can measure distances to the thousandth of an inch. It provides step-by-step instructions for taking a measurement using the sleeve scale, thimble scale and vernier scale. Students are asked to complete an in-class worksheet on using vernier calipers and micrometers and to finish any unfinished portions as homework. They are also assigned a self-test in their textbook on micrometer measurements as additional homework.