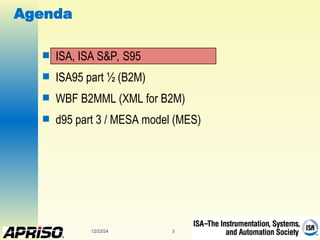

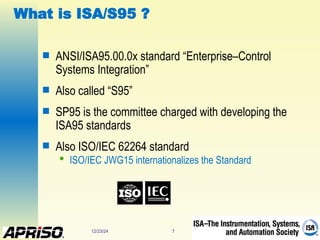

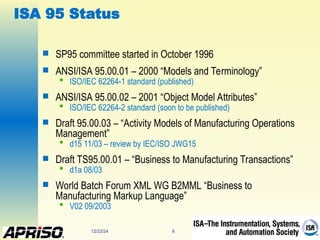

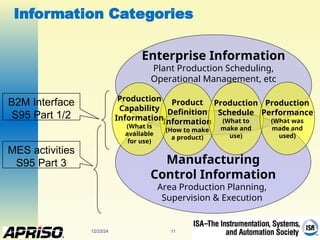

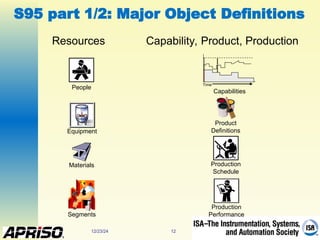

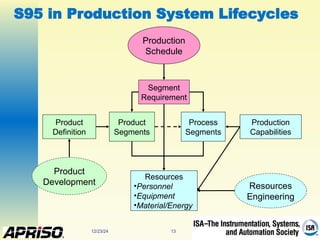

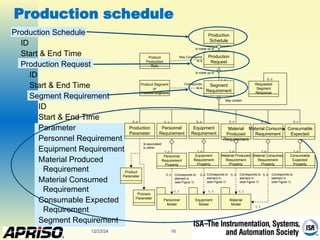

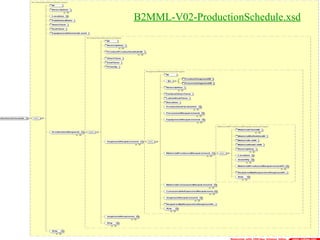

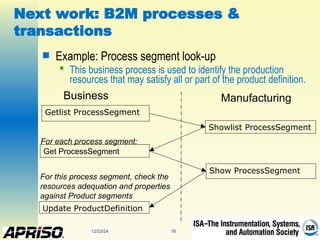

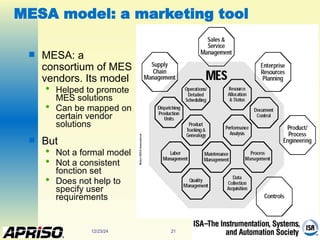

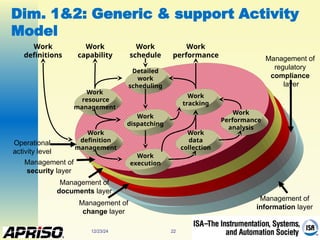

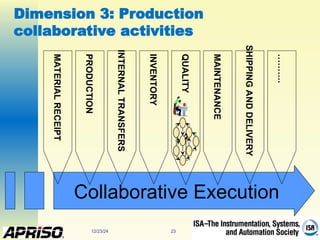

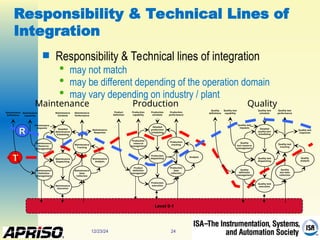

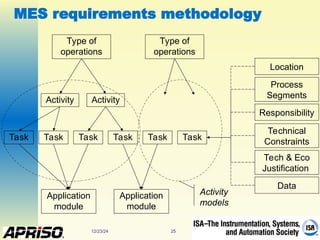

The document provides an overview of the ISA95 standard for enterprise-control systems integration, detailing its history, structure, and the responsibilities of its various committees. It outlines the categorization of information and object definitions within production systems, emphasizing the standard's relevance in manufacturing operations management. The discussion also highlights the technical integration and collaboration between different activities in manufacturing and maintenance, as well as ongoing efforts to enhance definitions and methodologies in the MES (Manufacturing Execution System) domain.