Pharmaceutical packaging serves several important functions:

1) It protects drugs from external environmental factors like light, moisture, and contamination.

2) Packaging identifies drug products, provides instructions for proper use, and ensures safety and efficacy.

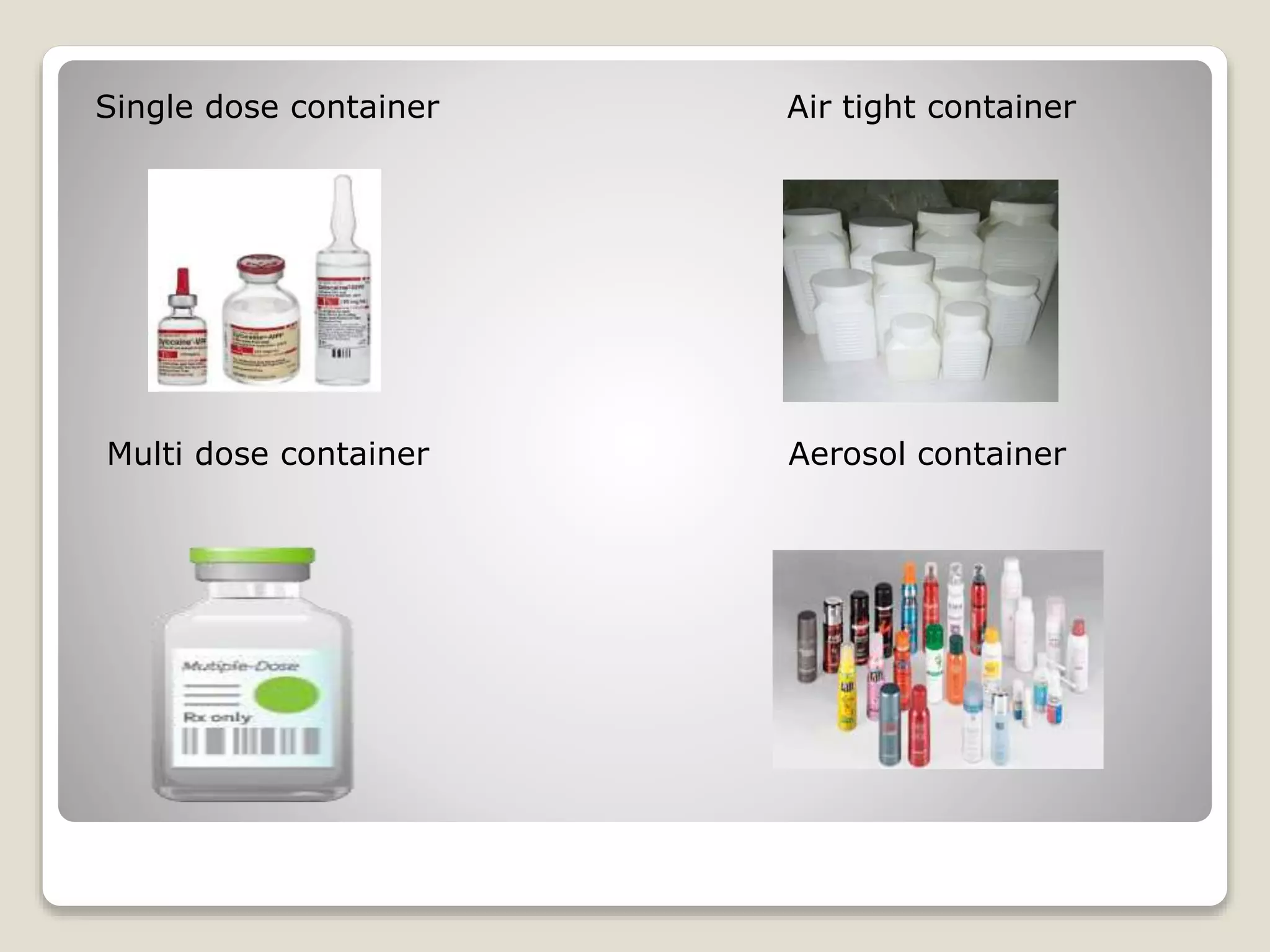

3) Packaging types include bottles, blister packs, vials, and other containers/closures that are evaluated through testing to ensure sterility, integrity, and that they do not interact with drug contents.