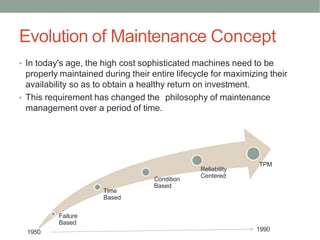

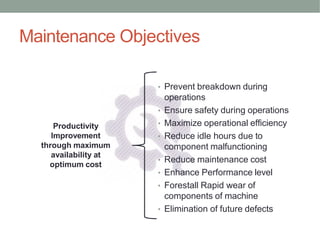

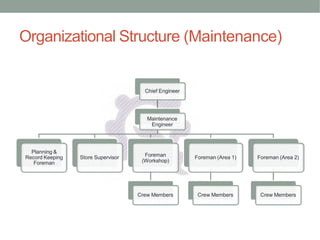

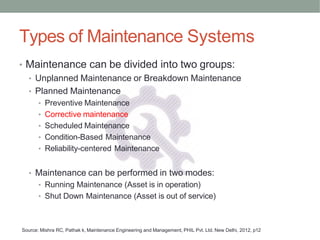

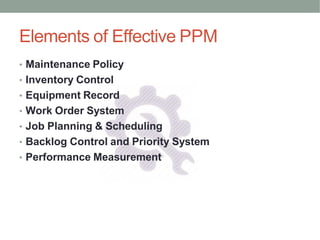

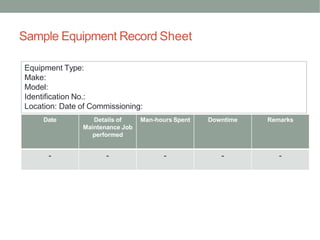

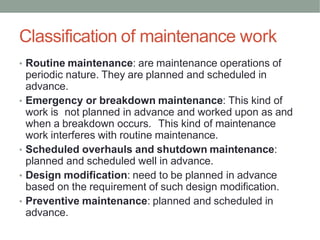

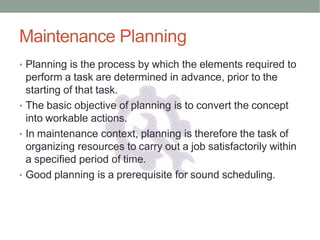

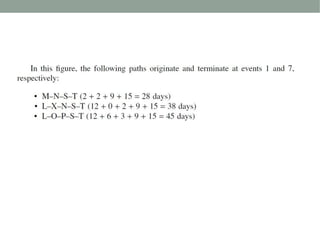

This document provides an overview of maintenance management. It defines various types of maintenance including breakdown, preventive, predictive, and reliability-centered maintenance. It discusses the evolution of maintenance concepts from breakdown-based to more modern condition-based approaches. The responsibilities of the maintenance department include personnel management, scheduling, inventory control, and financial management. Effective maintenance requires establishing objectives, planning and executing maintenance activities, and providing feedback and control.