Embed presentation

Downloaded 102 times

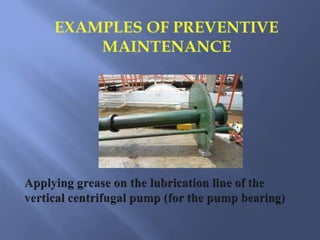

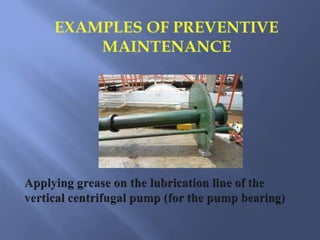

The document discusses preventive maintenance, which involves regularly maintaining equipment through activities like cleaning, inspection, and tightening to reduce the likelihood of failure. Preventive maintenance helps protect assets and prolong equipment life, improve reliability, decrease downtime and costs, and reduce injuries. It is suitable for equipment that has critical functions, failures that can be prevented through maintenance, and failure risks that increase over time. Preventive maintenance is not suitable for equipment with random failures unrelated to maintenance or non-critical functions. While it provides benefits, preventive maintenance does not eliminate catastrophic failures and includes unnecessary activities that could potentially damage components.