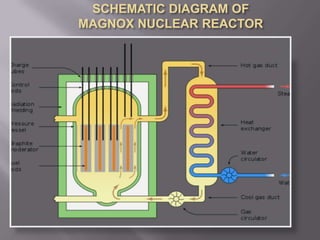

The document discusses Magnox nuclear reactors. Magnox reactors use natural uranium fuel clad in an alloy of magnesium called Magnox. They have a graphite moderator and use carbon dioxide as a coolant. Key features include low neutron capture cross-section of Magnox but low maximum temperature. The first Magnox reactors produced plutonium and electricity. They were later replaced by Advanced Gas-cooled Reactors but some remain in operation today.