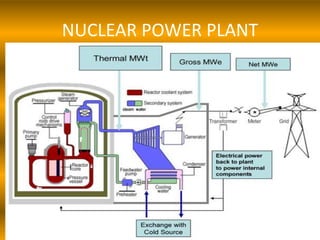

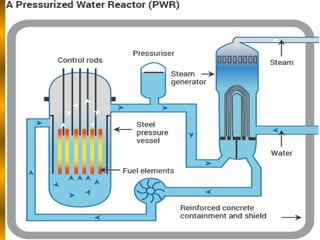

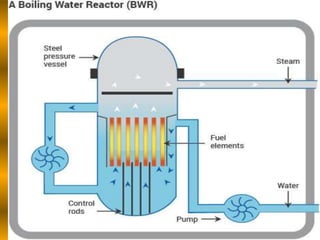

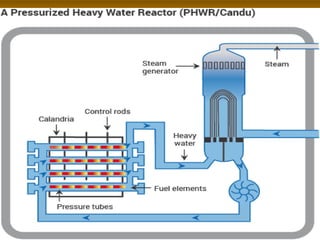

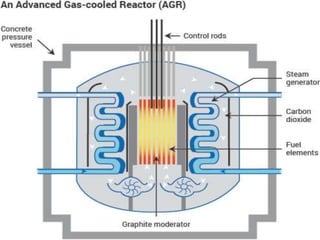

This document provides an overview of nuclear reactors. It discusses the basic components of a nuclear reactor including the fuel, moderator, control rods, coolant, pressure vessel, steam generator, and containment structure. It then describes several types of nuclear reactors in use: pressurized water reactors, boiling water reactors, pressurized heavy water reactors, advanced gas-cooled reactors, RBMK reactors, and fast neutron reactors. The document also discusses refueling of reactors, lifetime extensions, and replacement of components over time to maintain safety and performance.