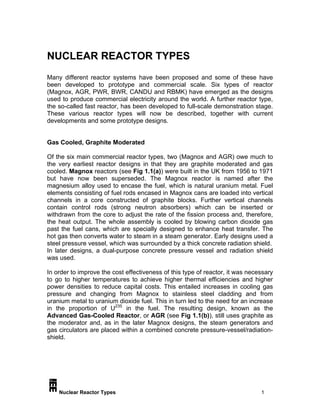

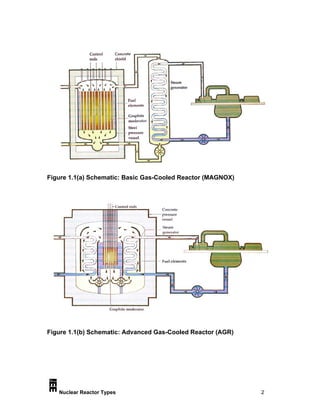

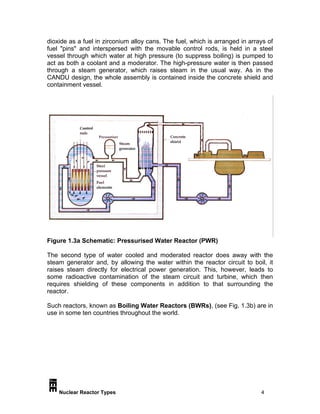

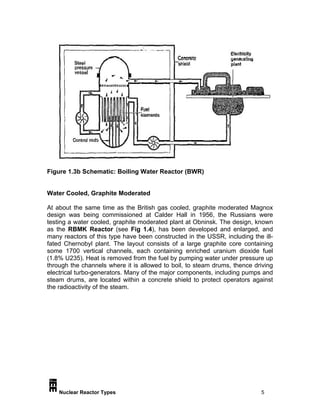

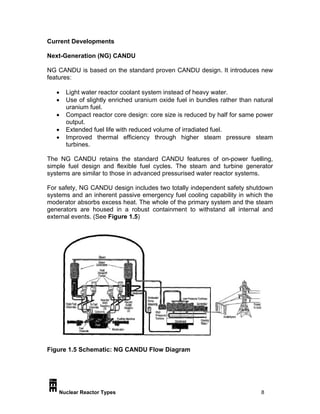

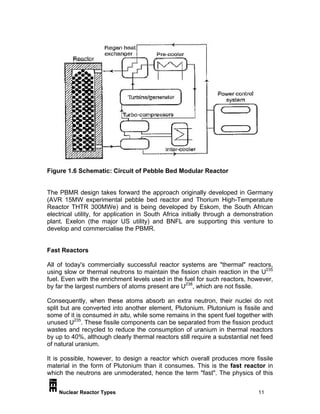

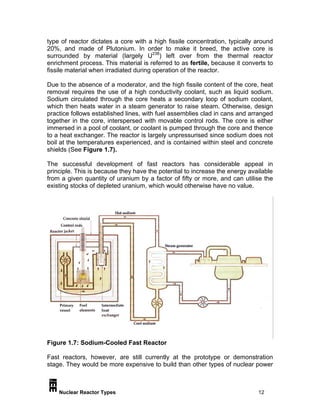

This document provides information on various types of nuclear reactors, including their basic designs and operating principles. It describes six main commercial reactor types (Magnox, AGR, PWR, BWR, CANDU, RBMK), as well as prototype designs like the IRIS, PBMR and fast reactors. Key details are given for each type such as coolant, moderator, fuel type, operating temperatures and pressures. Current developments discussed include the Next Generation CANDU and Advanced PWR designs.