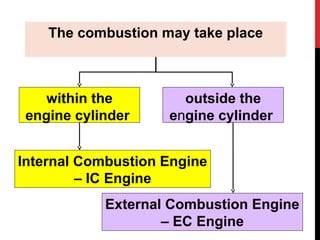

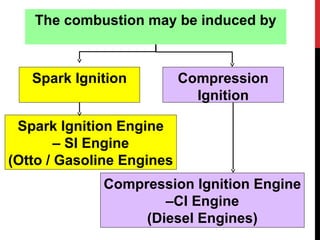

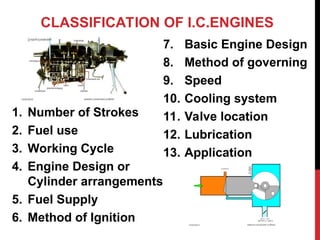

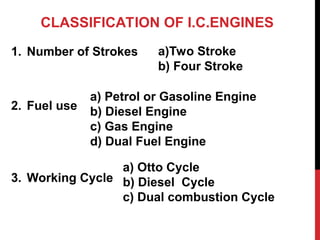

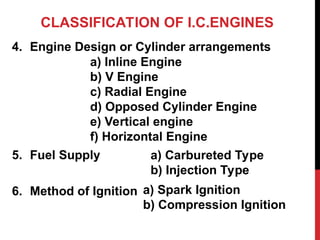

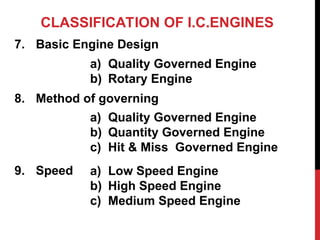

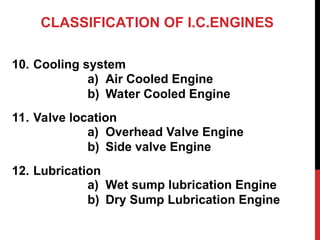

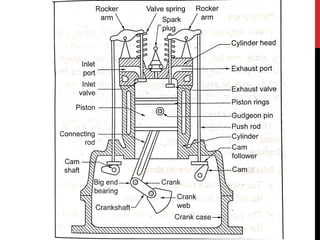

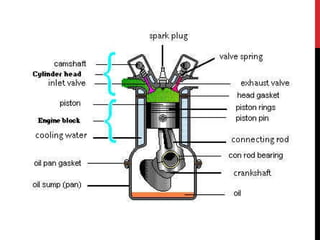

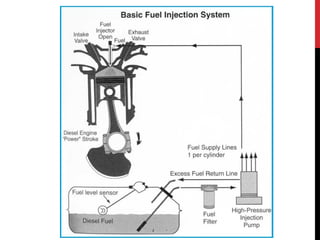

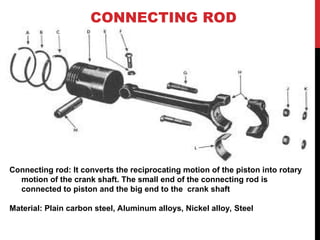

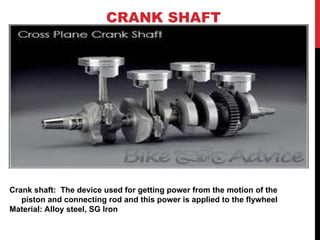

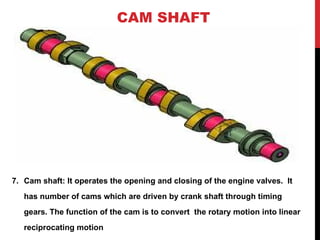

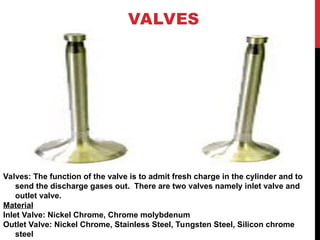

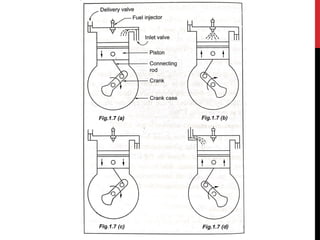

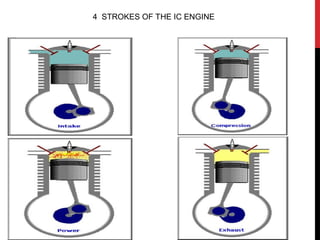

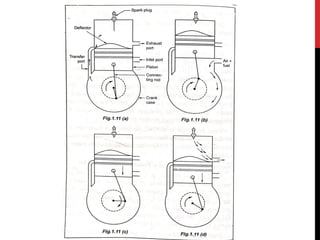

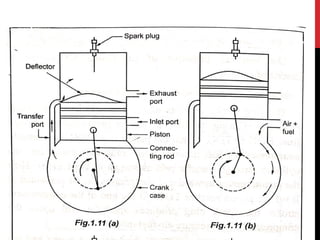

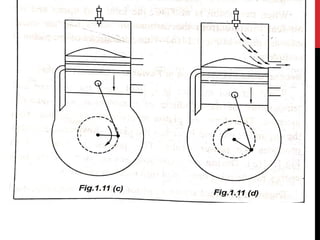

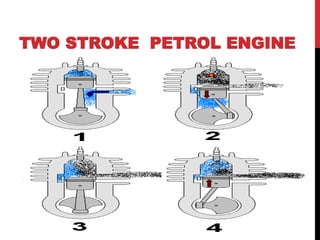

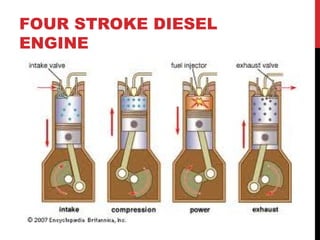

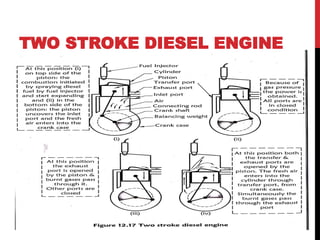

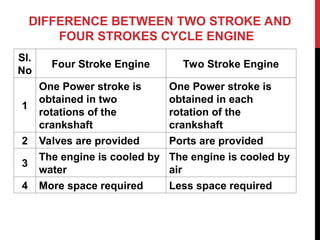

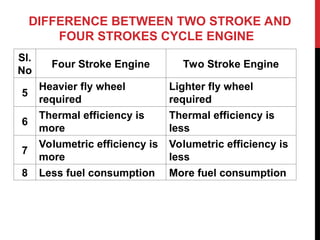

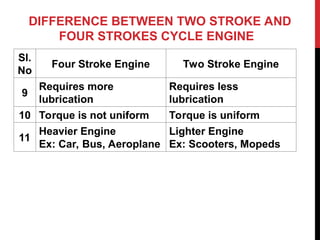

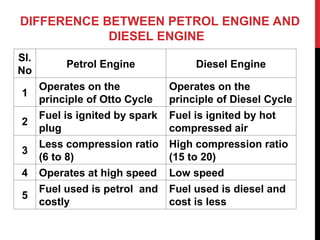

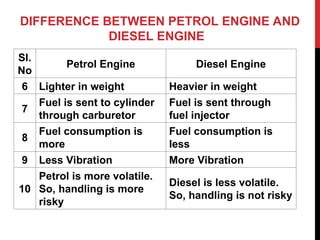

The document provides an overview of internal combustion engines (IC engines), detailing their historical development, fundamental principles, and classifications based on various criteria. It distinguishes between two-stroke and four-stroke engines, along with different types such as petrol and diesel engines, highlighting their distinct operational mechanisms and performance characteristics. Additionally, it describes key components of an IC engine, including the cylinder, piston, crankshaft, and valves, outlining their functions and materials used.