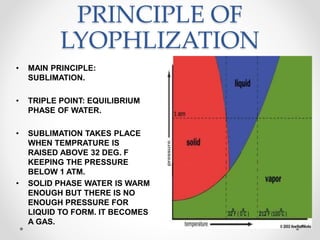

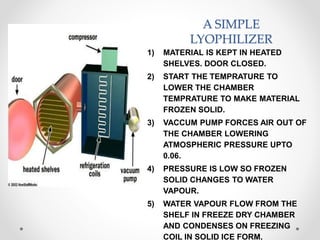

Lyophilization, also known as freeze drying, is a process that removes water from a material through sublimation while preserving its structure and composition. It works by first freezing the material and then reducing the pressure and increasing the temperature to allow the frozen water to change directly from solid to gas without passing through the liquid phase. A simple lyophilizer freezes materials on heated shelves, lowers the chamber pressure to 0.06 atmospheres using a vacuum pump, causing the frozen water to sublimate into a gas and condense on a freezing coil outside the chamber. Lyophilization is used to preserve bacterial and viral cultures, dry numerous products, and store water-damaged materials like manuscripts.