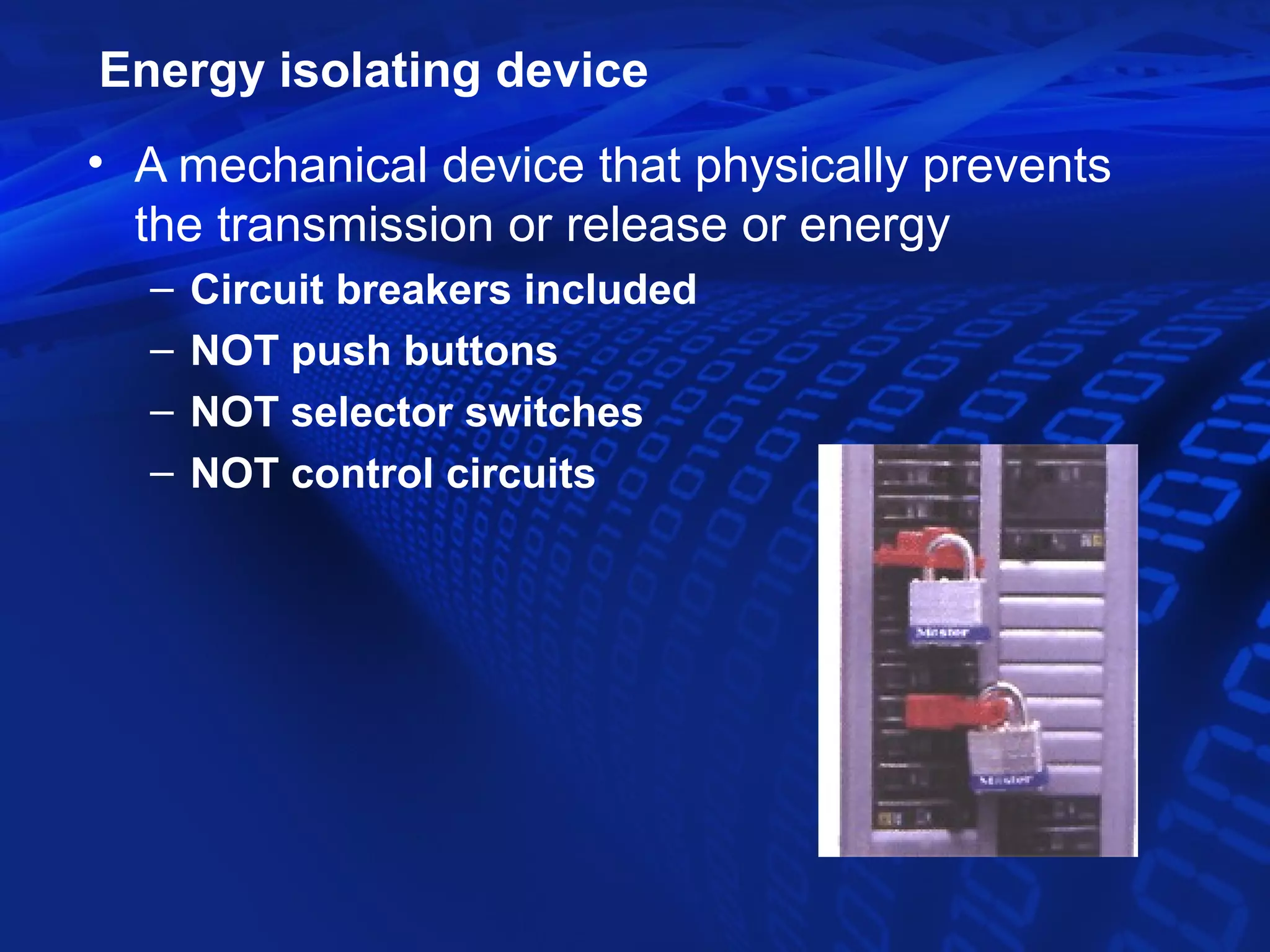

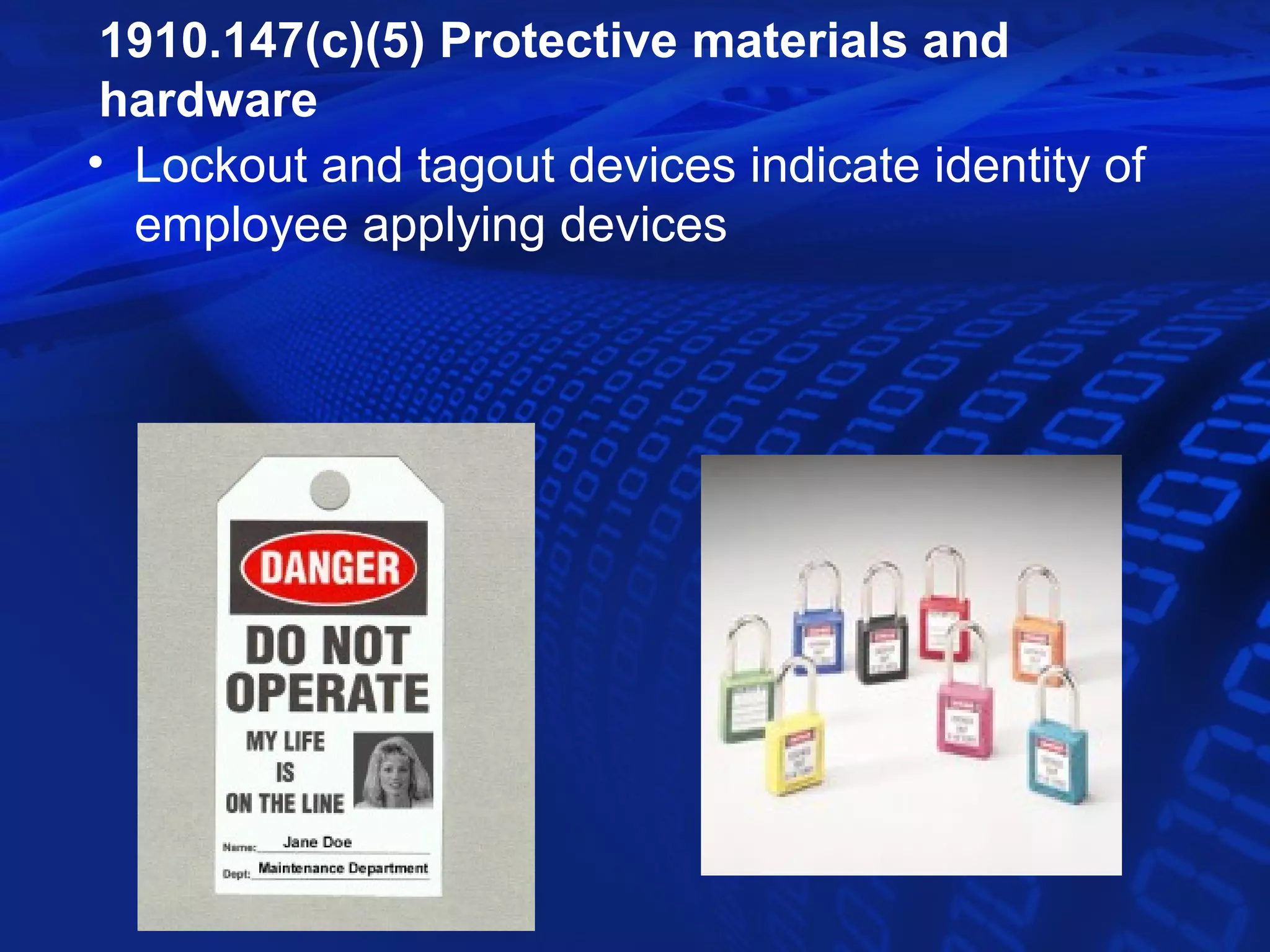

The document summarizes OSHA's lockout/tagout standard 1910.147. It covers the scope of the standard, definitions of key terms, requirements for an energy control program including procedures, training, periodic inspections, protective materials and devices. It describes the application and removal of lockout/tagout controls and exceptions for testing, outside personnel, group lockouts and shift changes. The overall purpose is to establish procedures to prevent unexpected startup of machines during service or maintenance which could cause injury to employees.