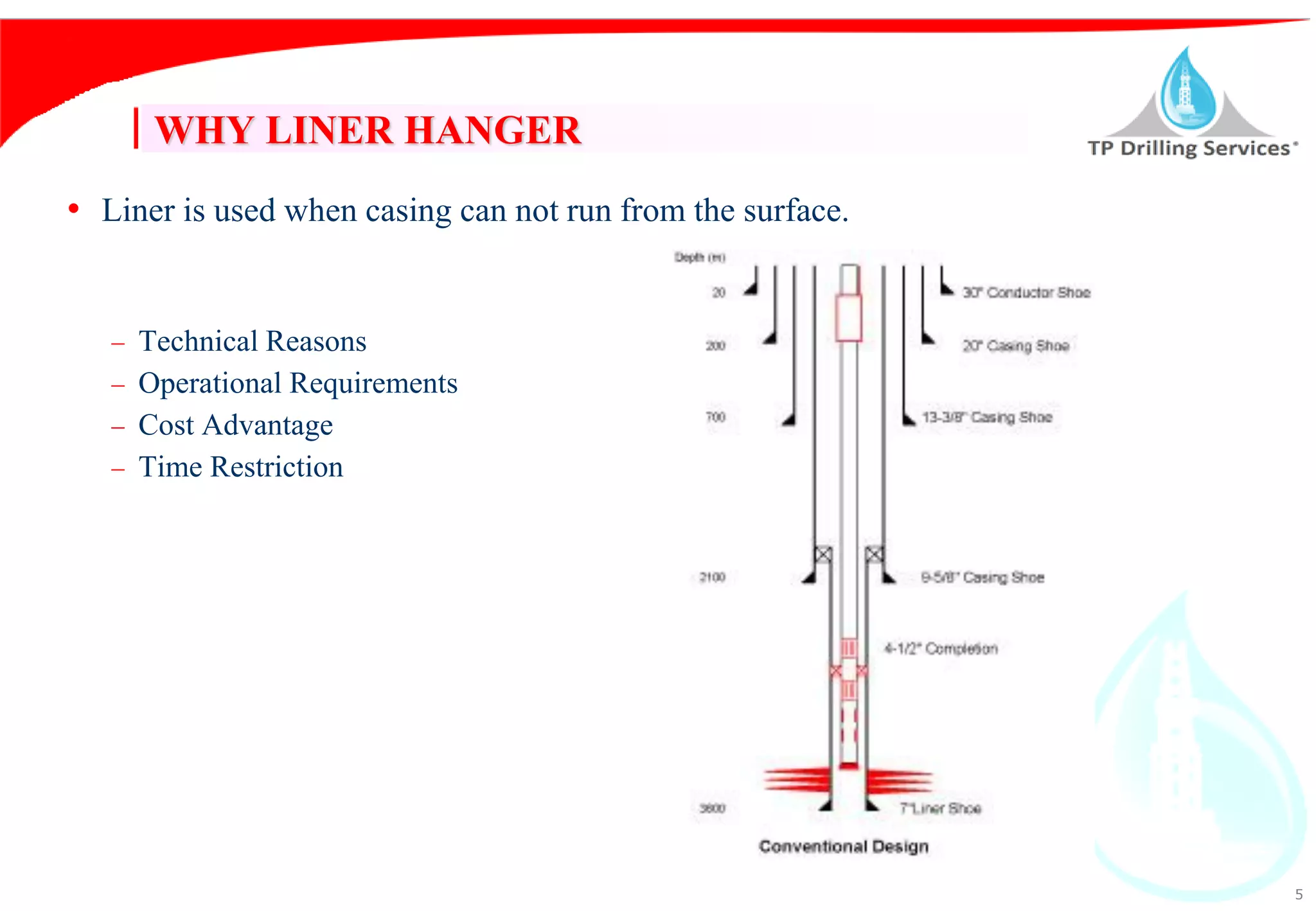

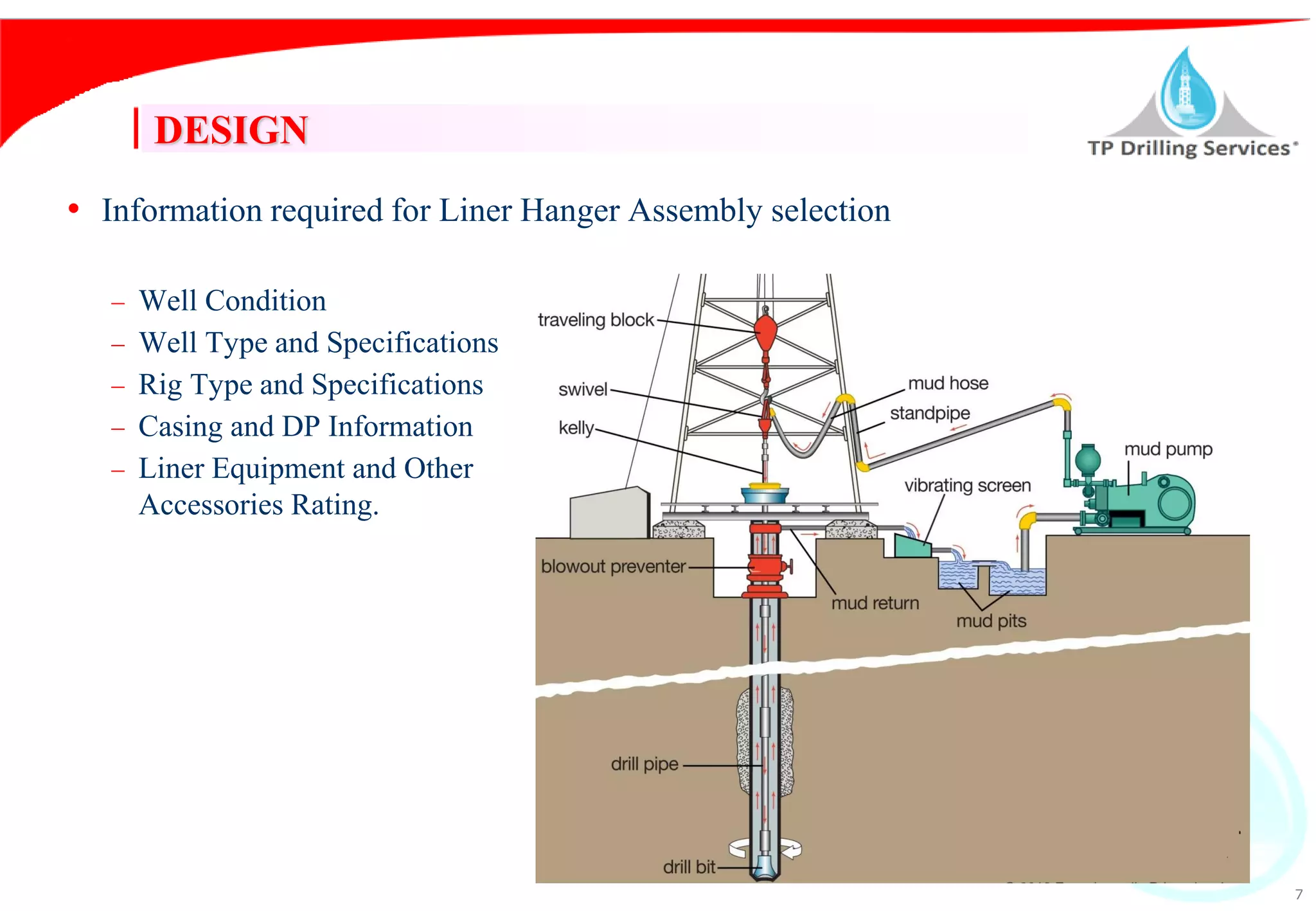

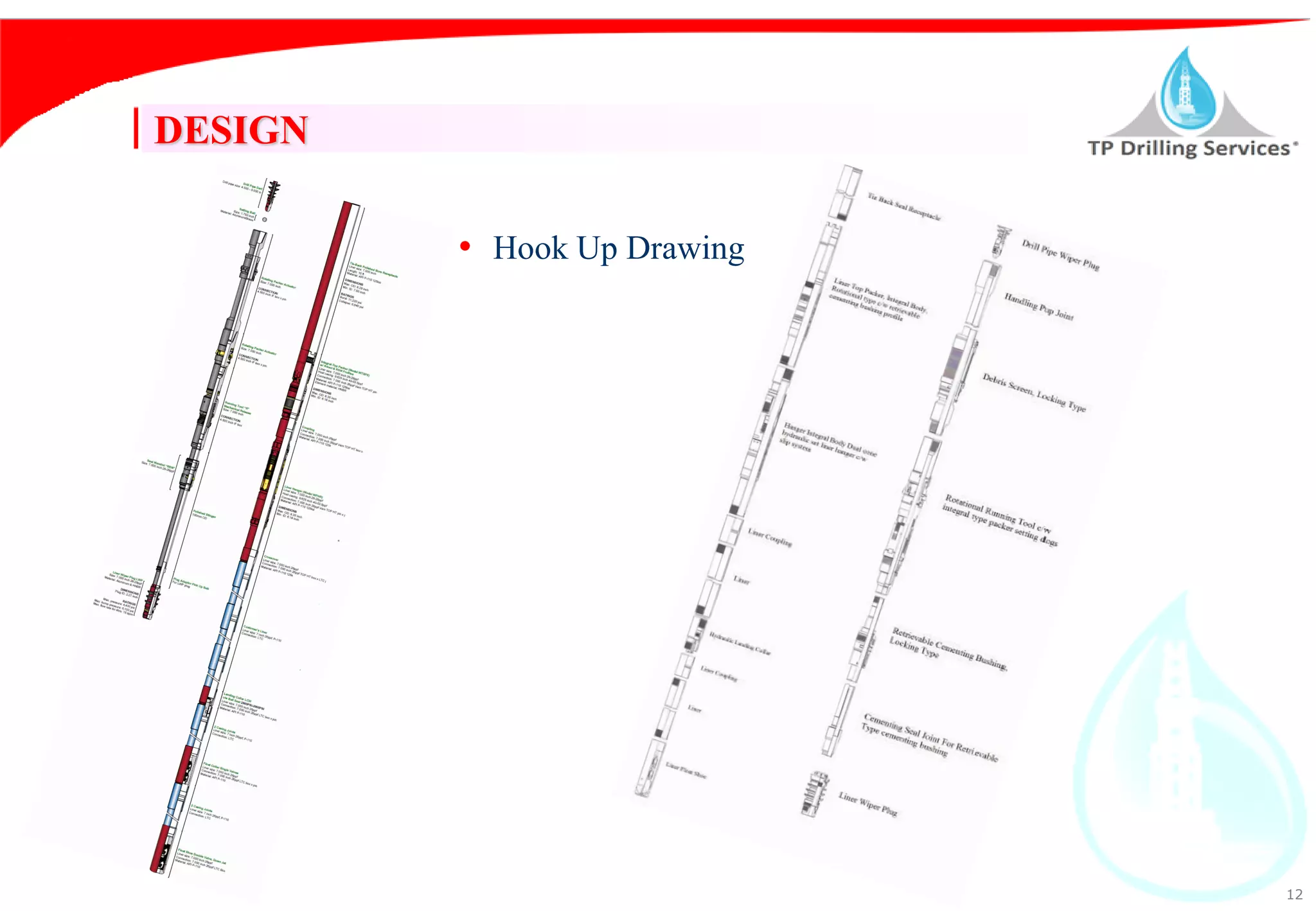

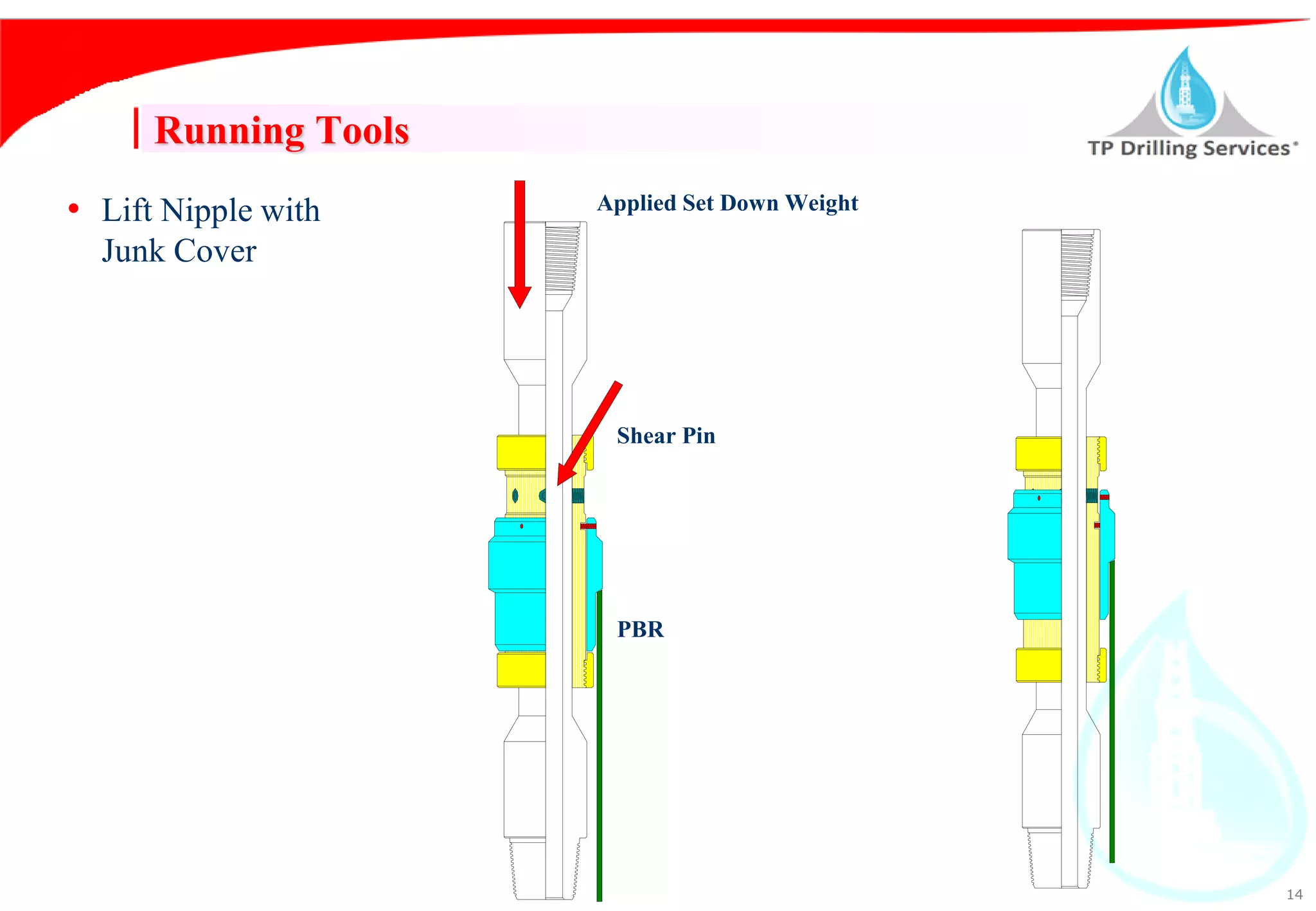

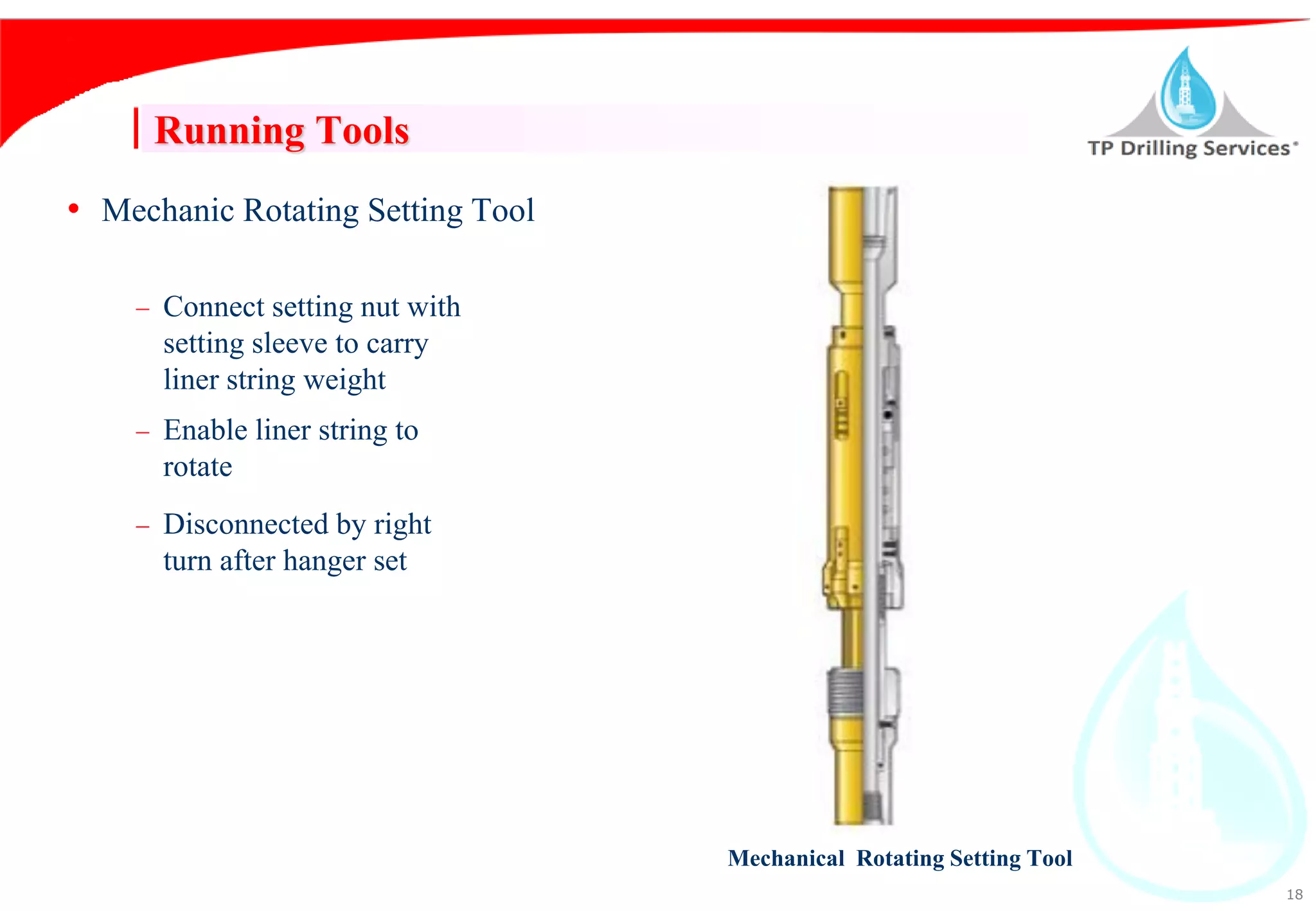

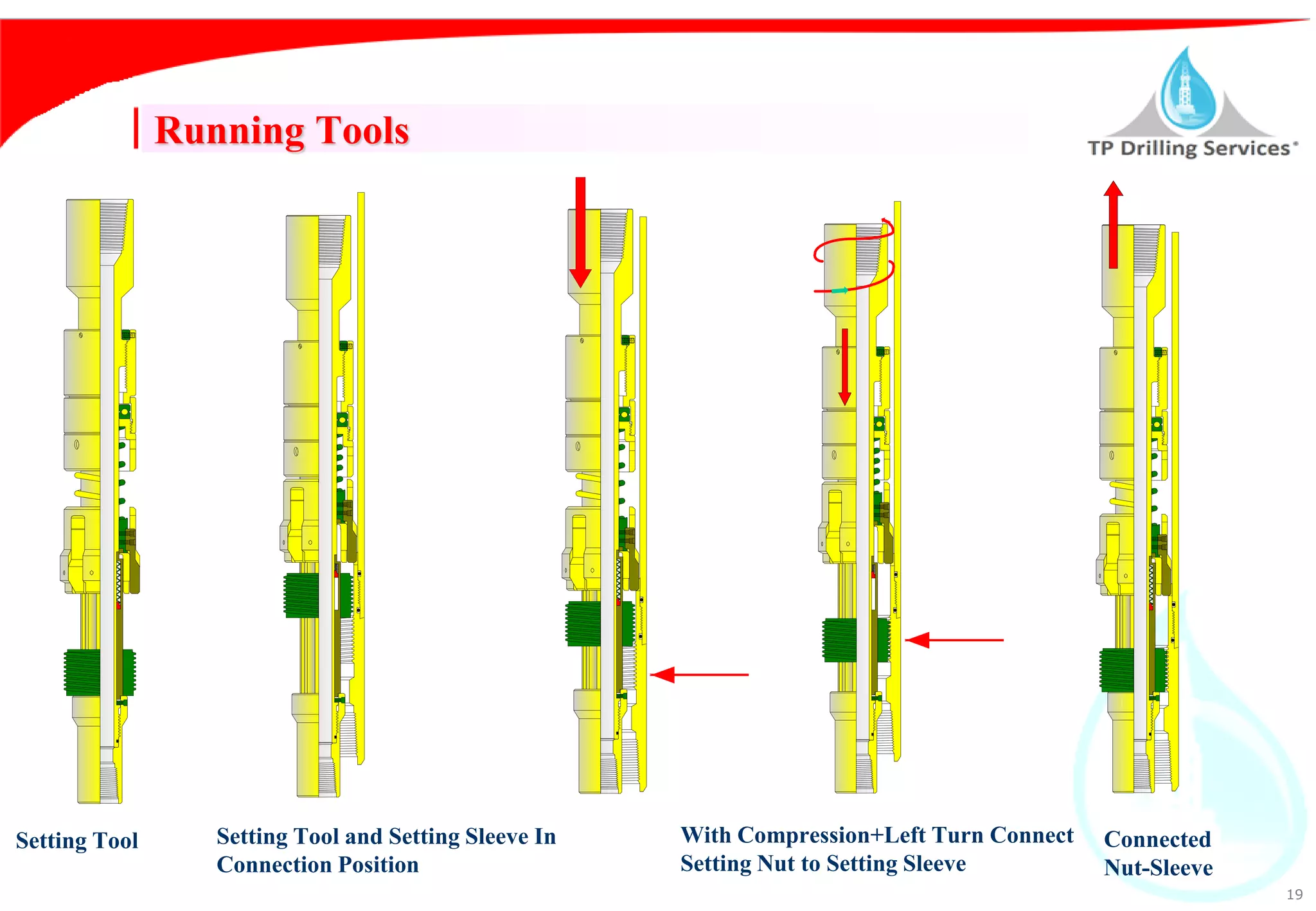

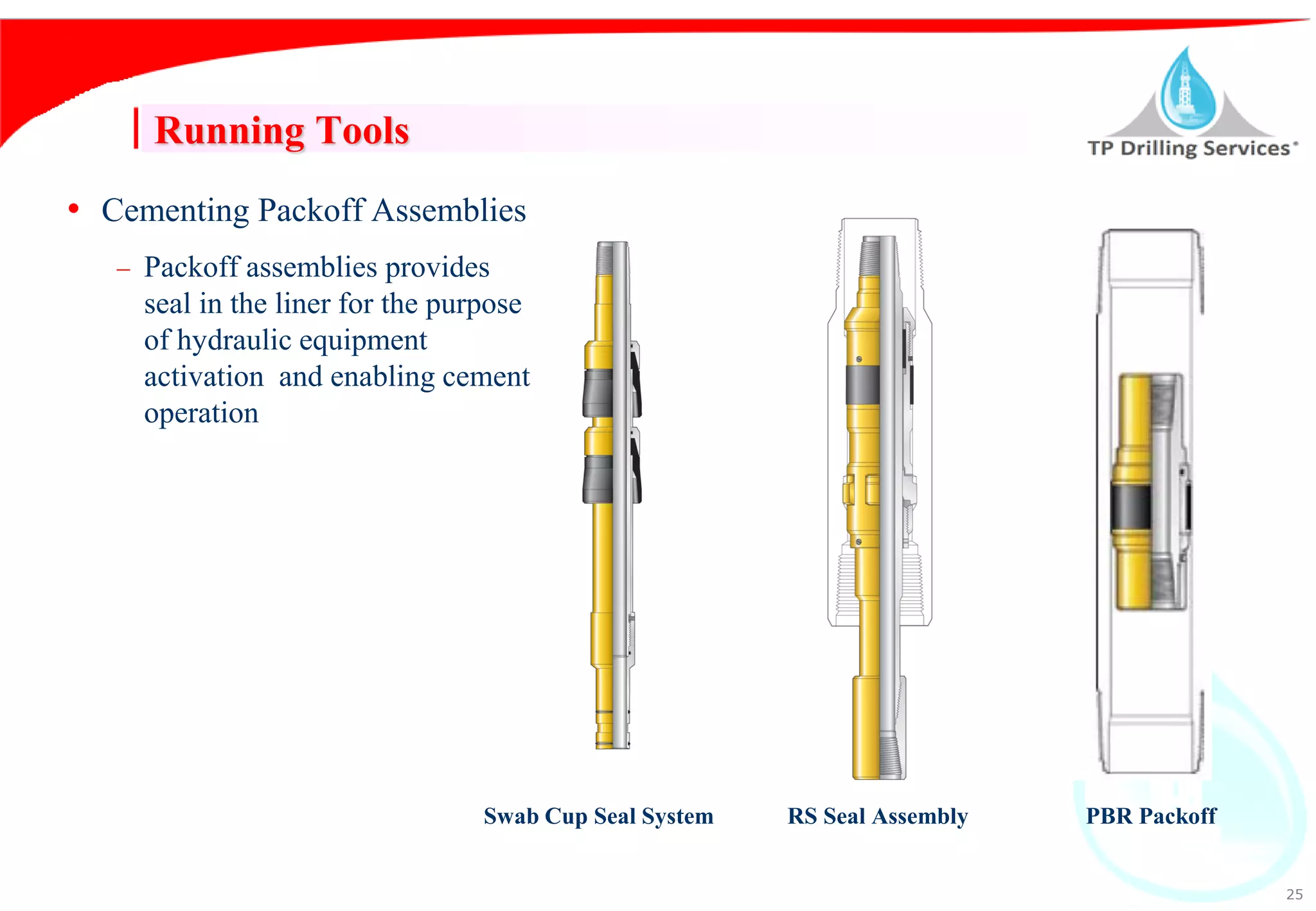

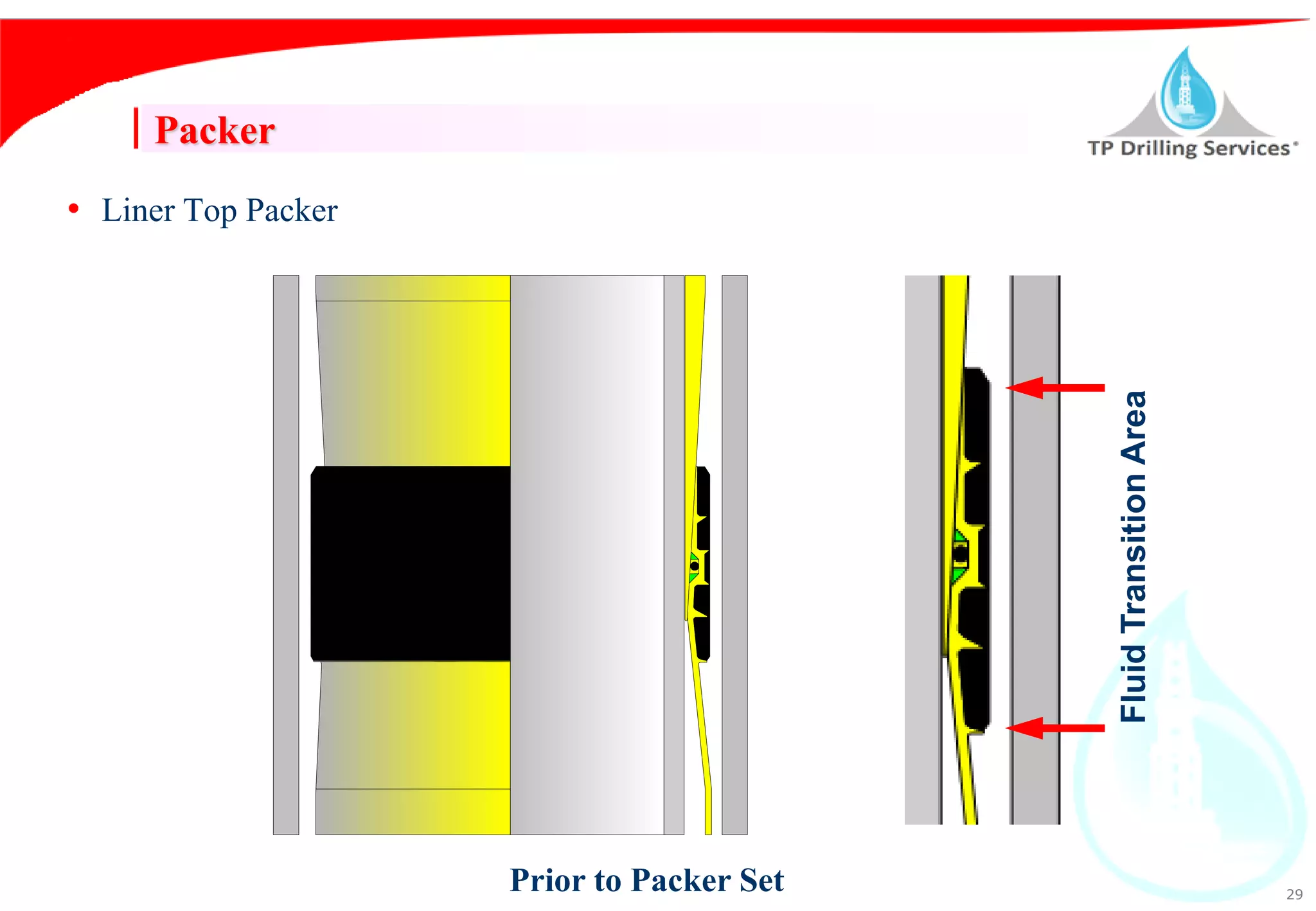

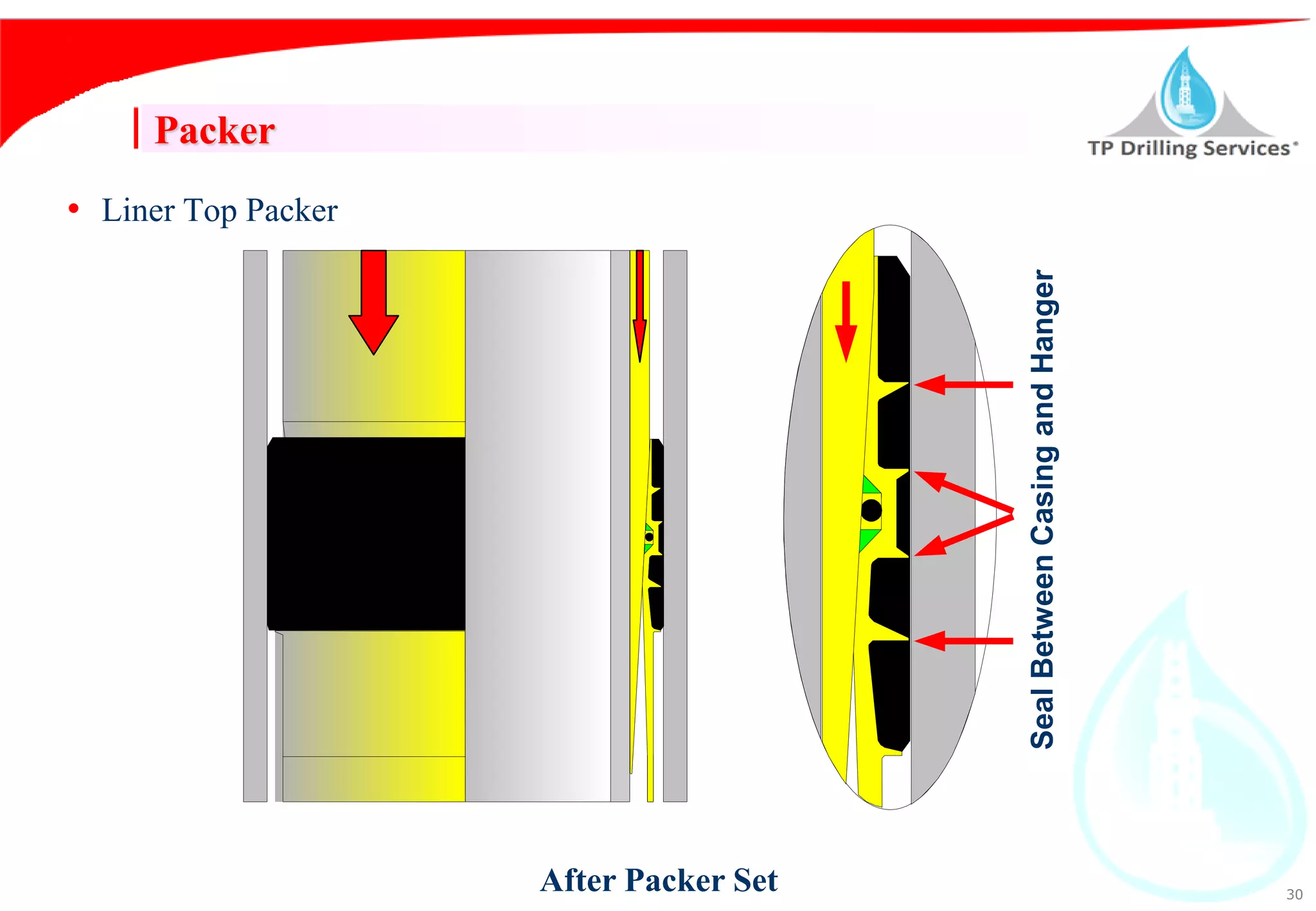

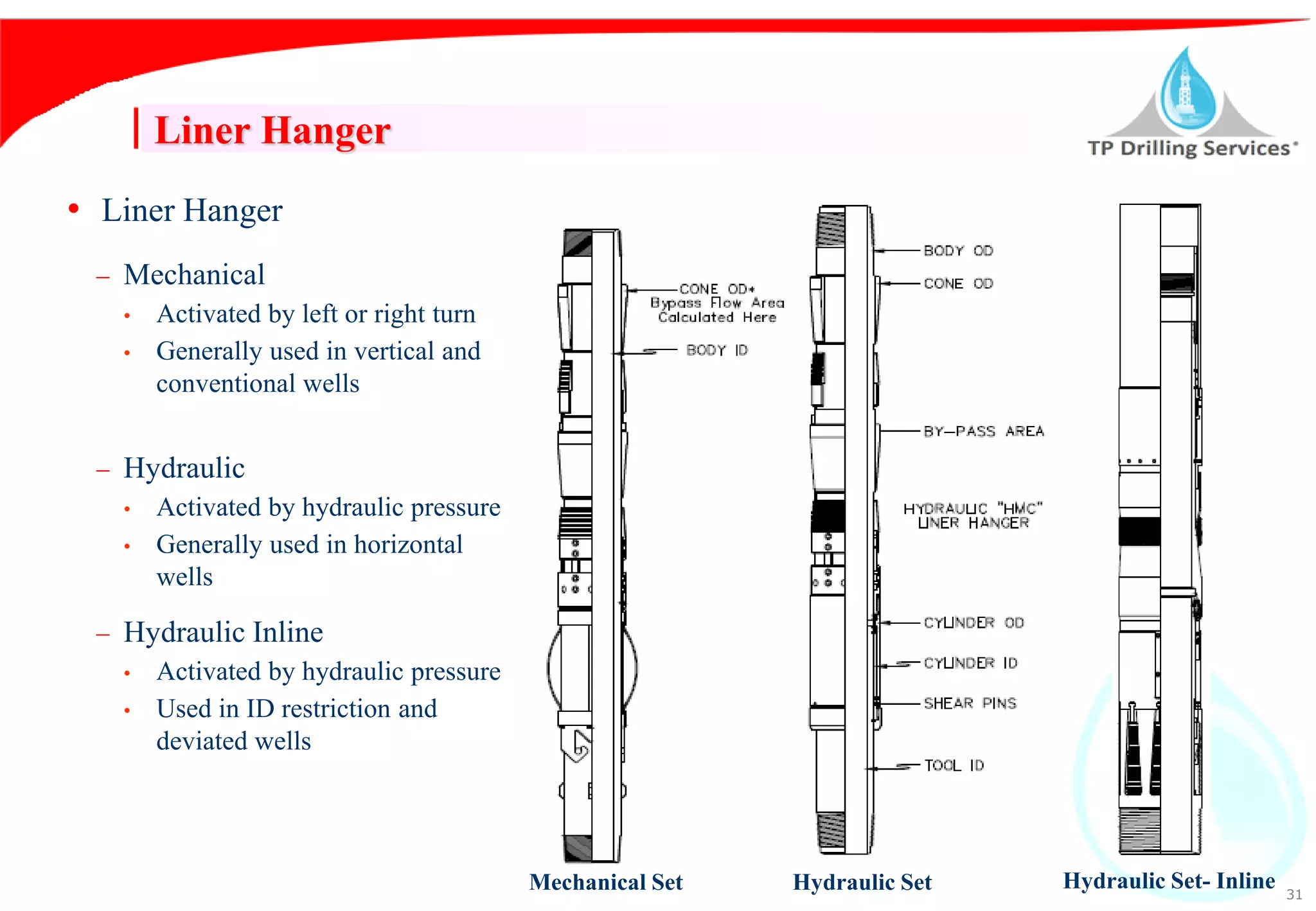

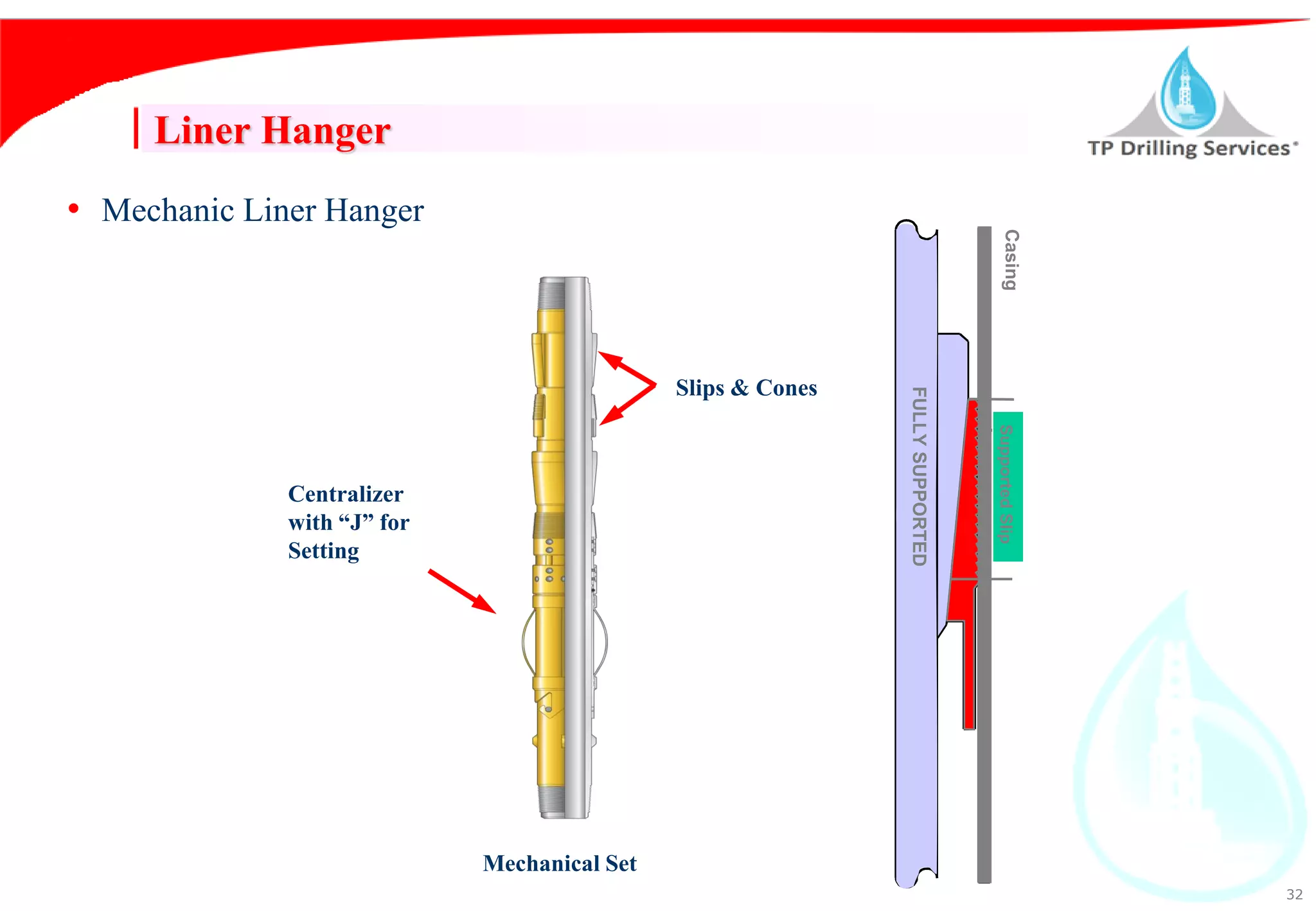

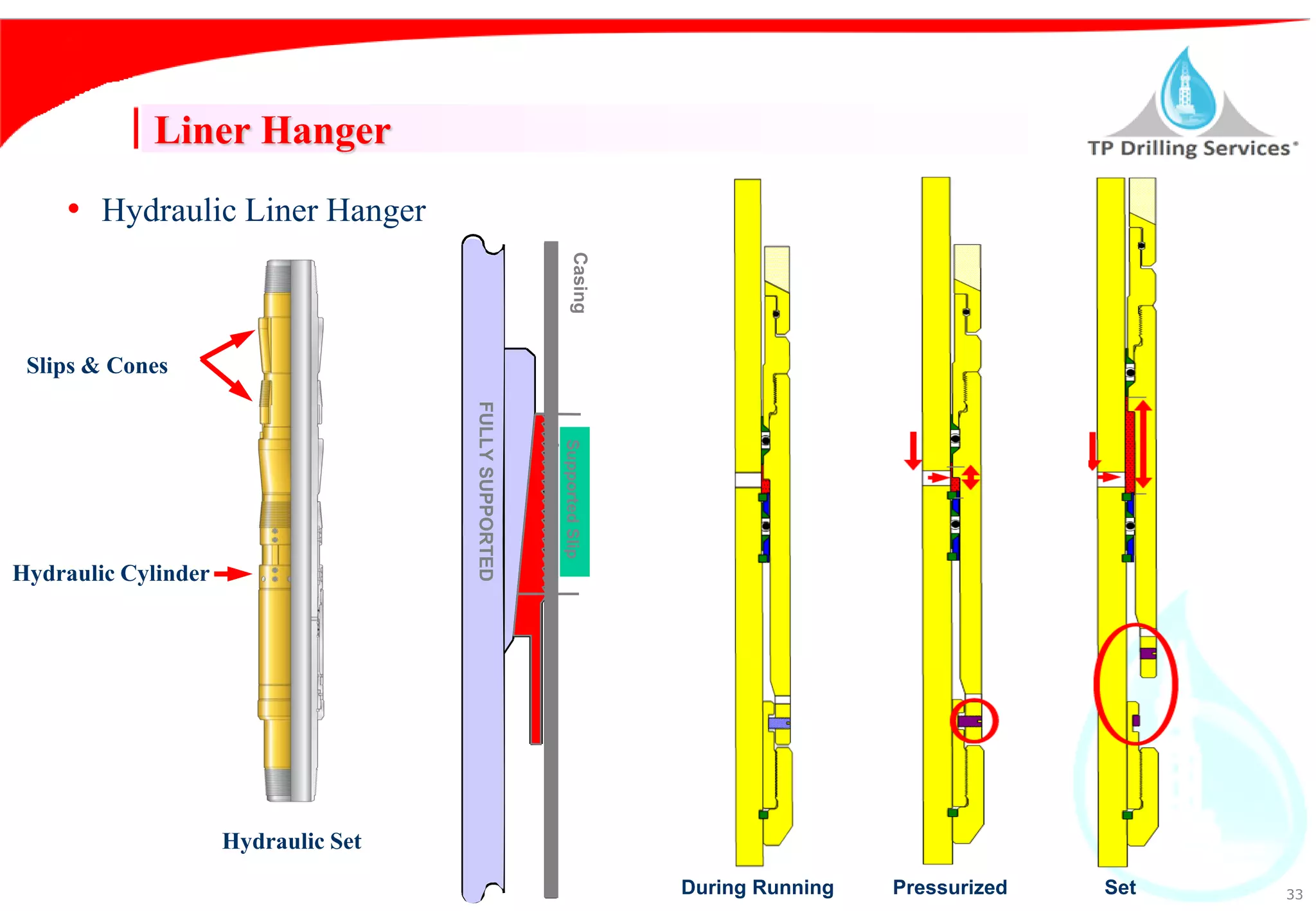

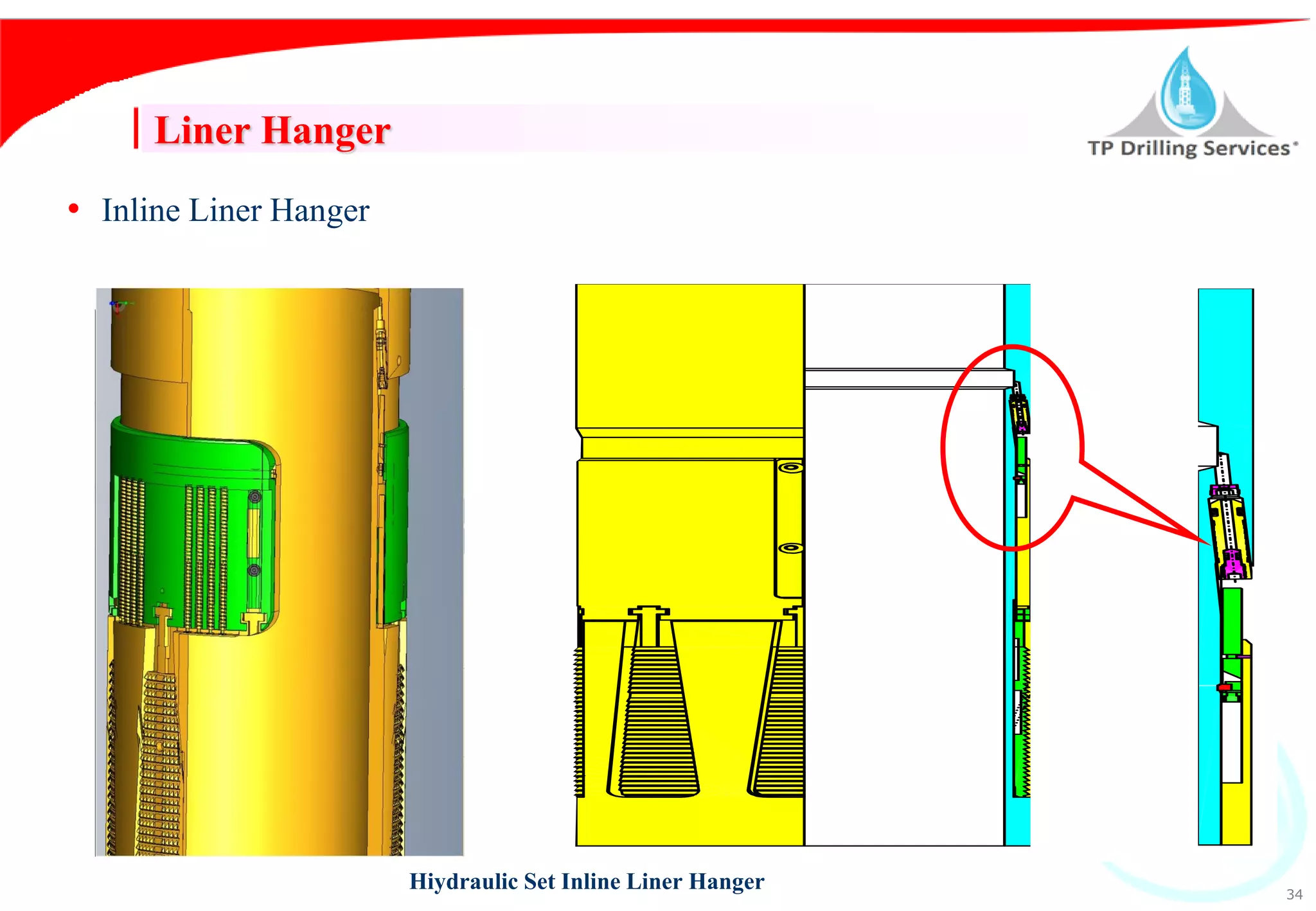

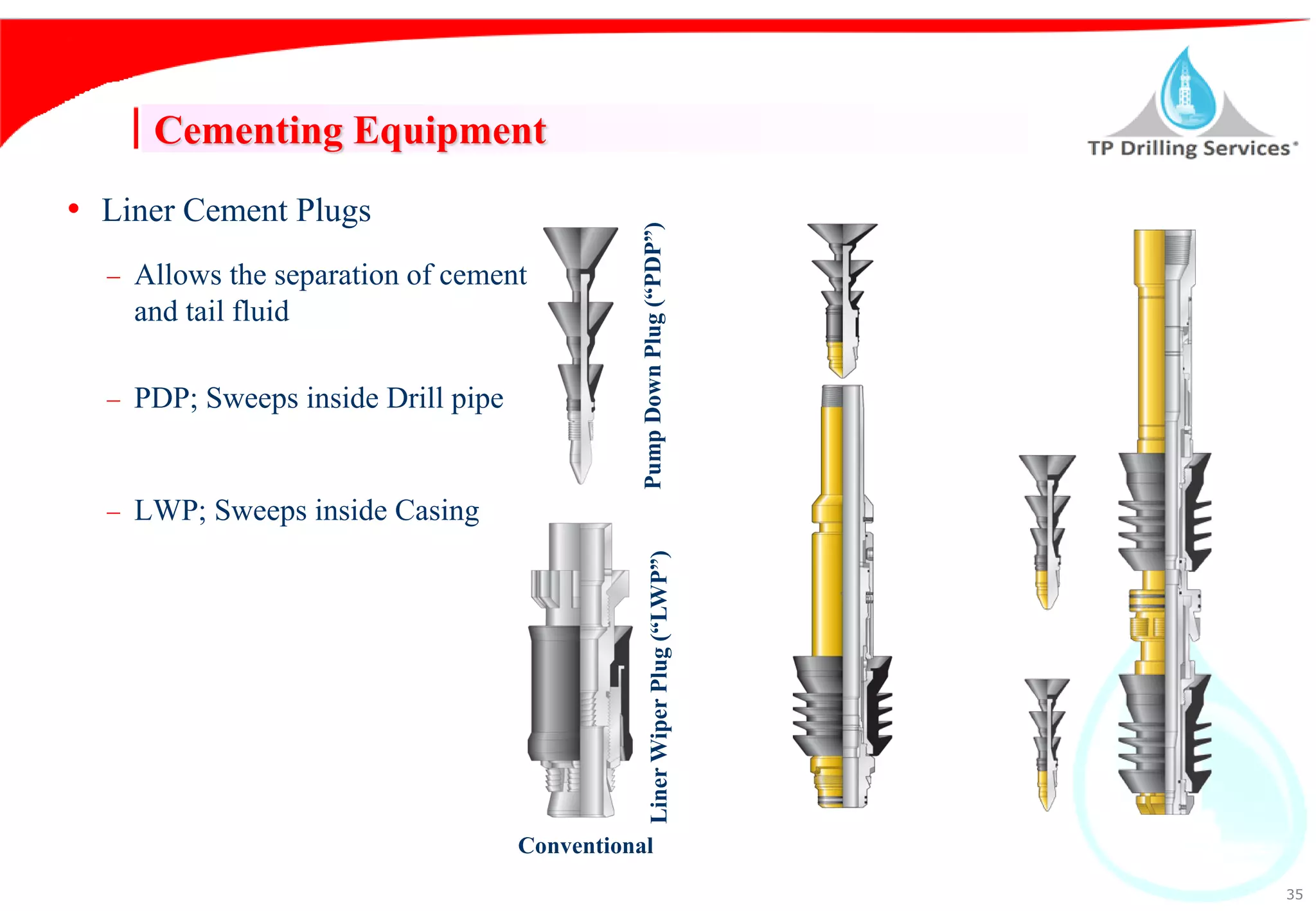

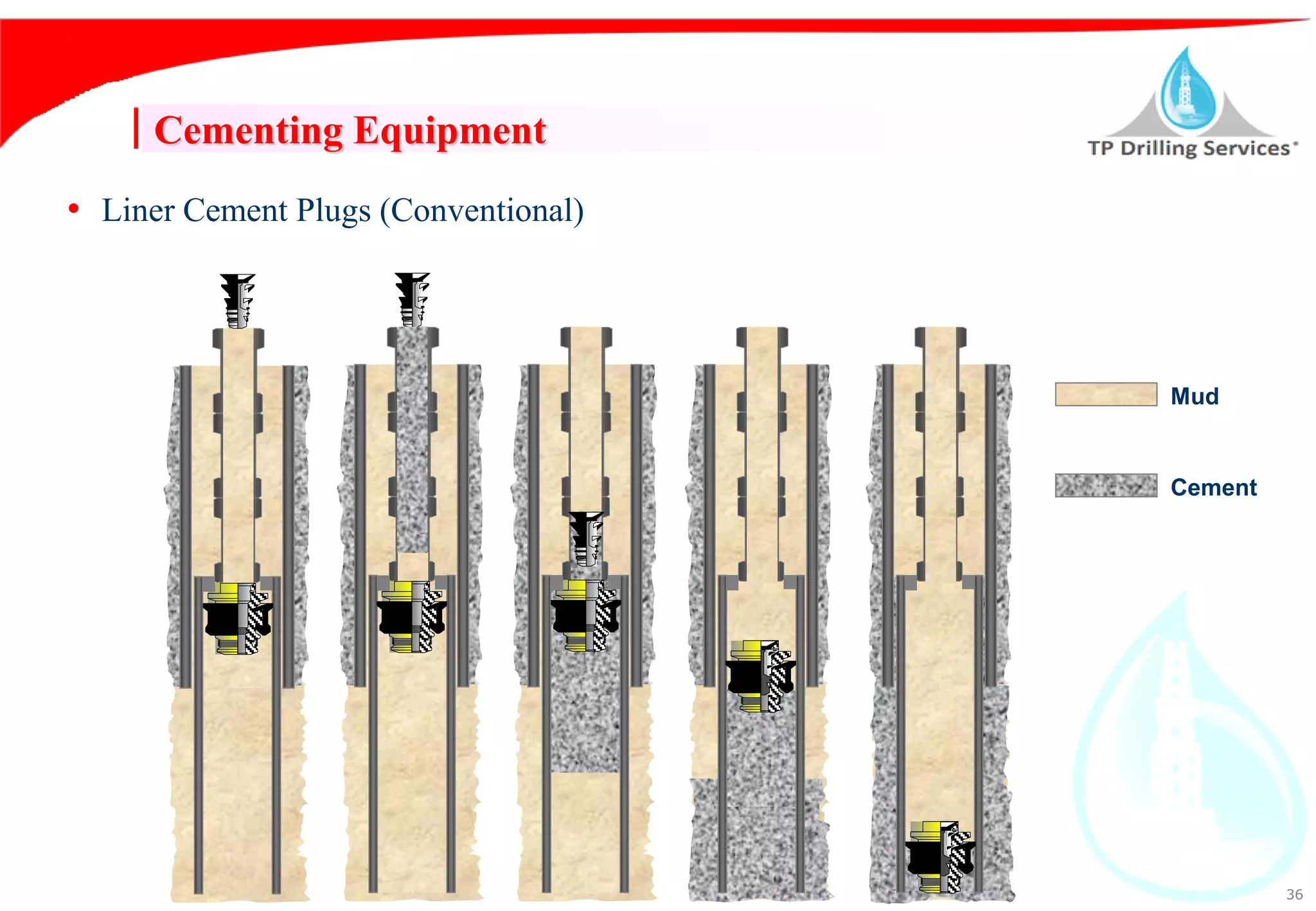

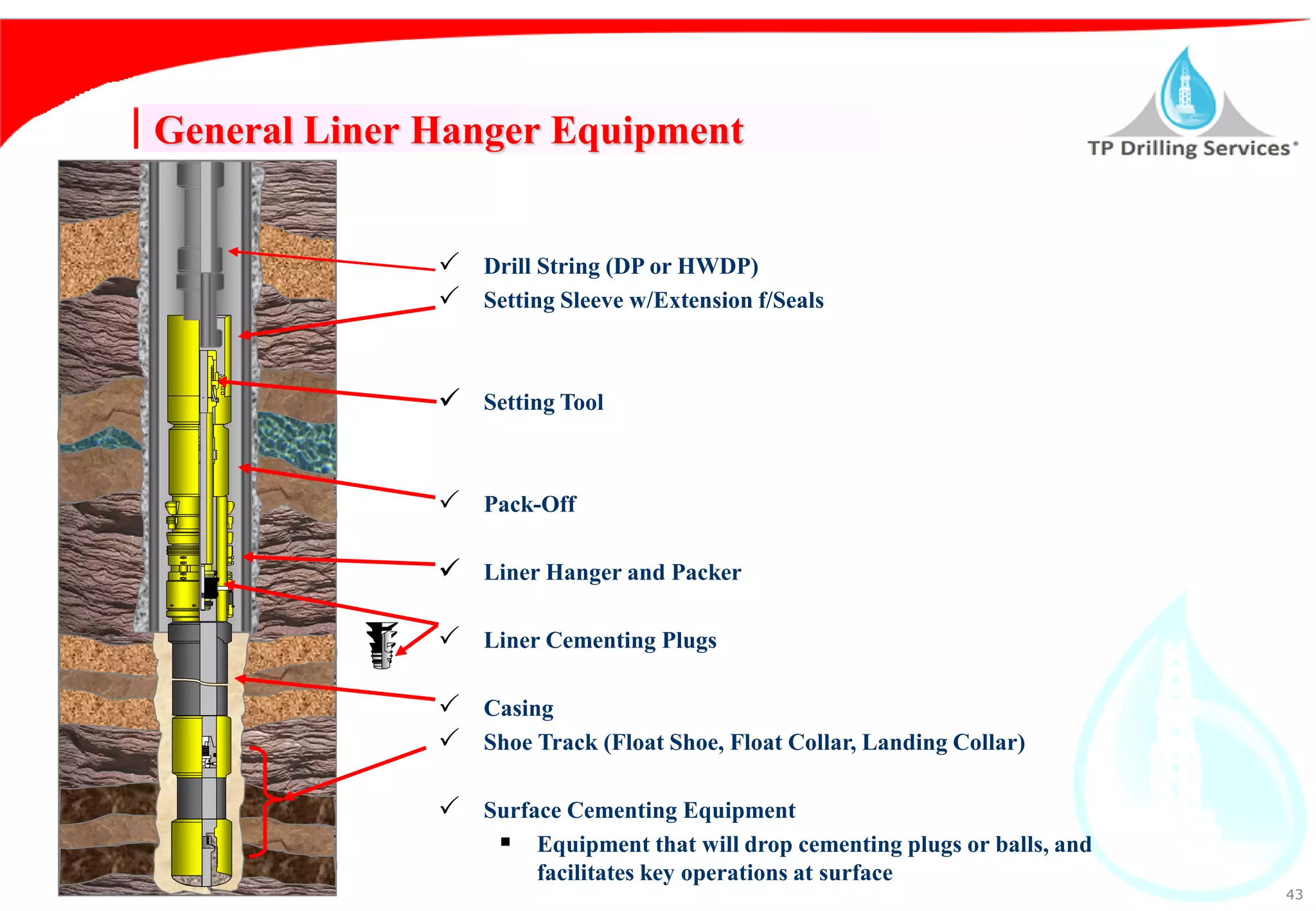

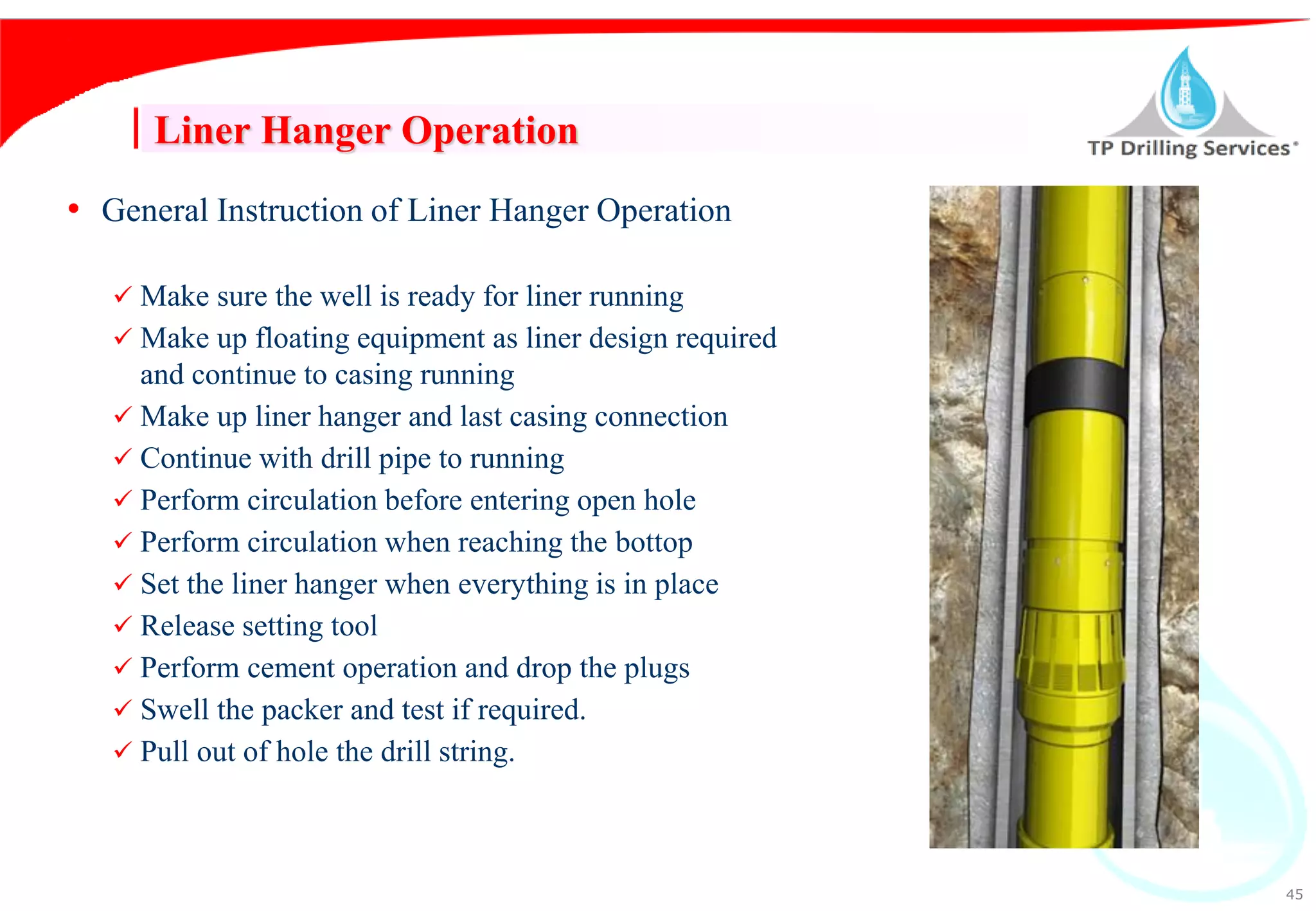

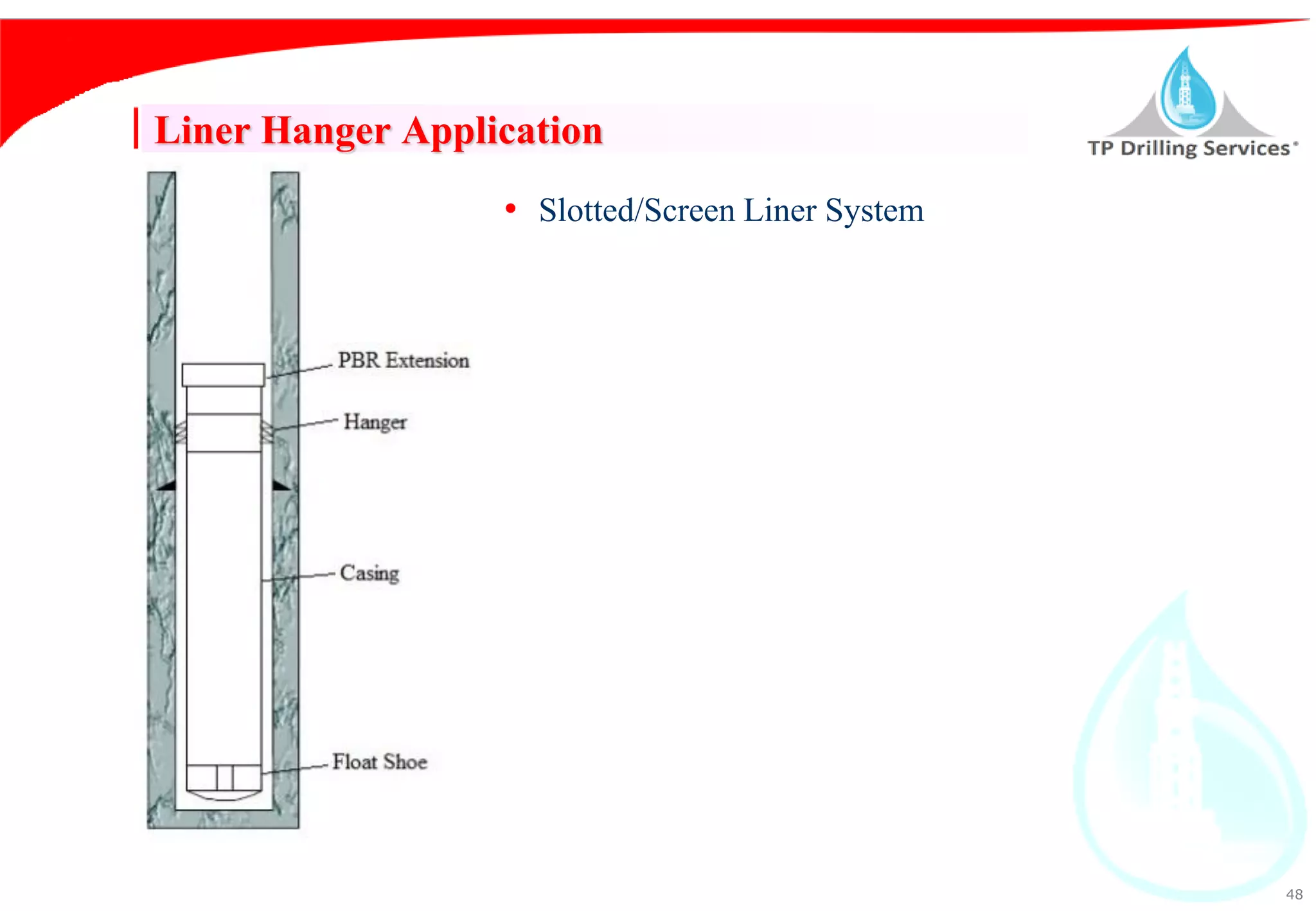

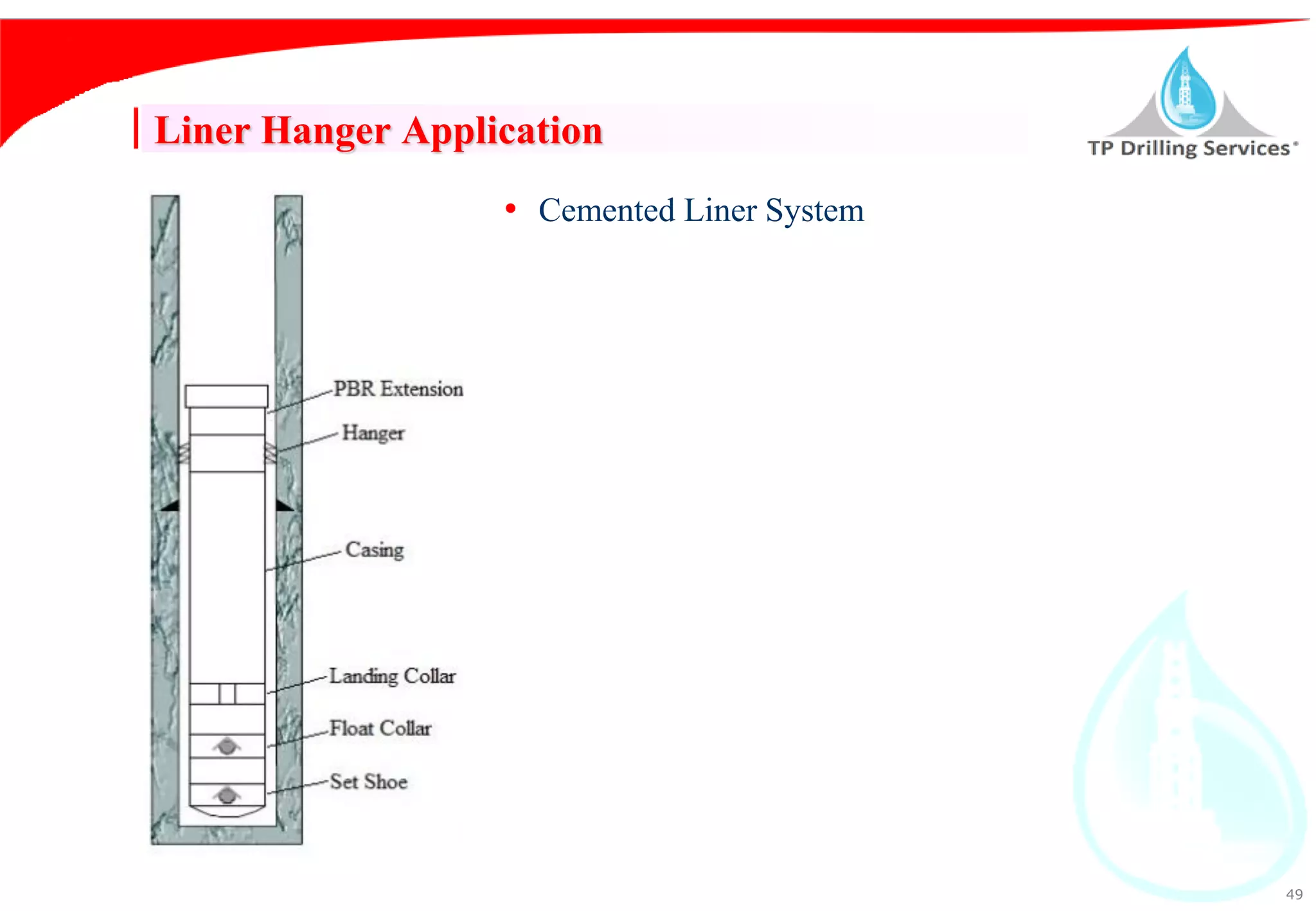

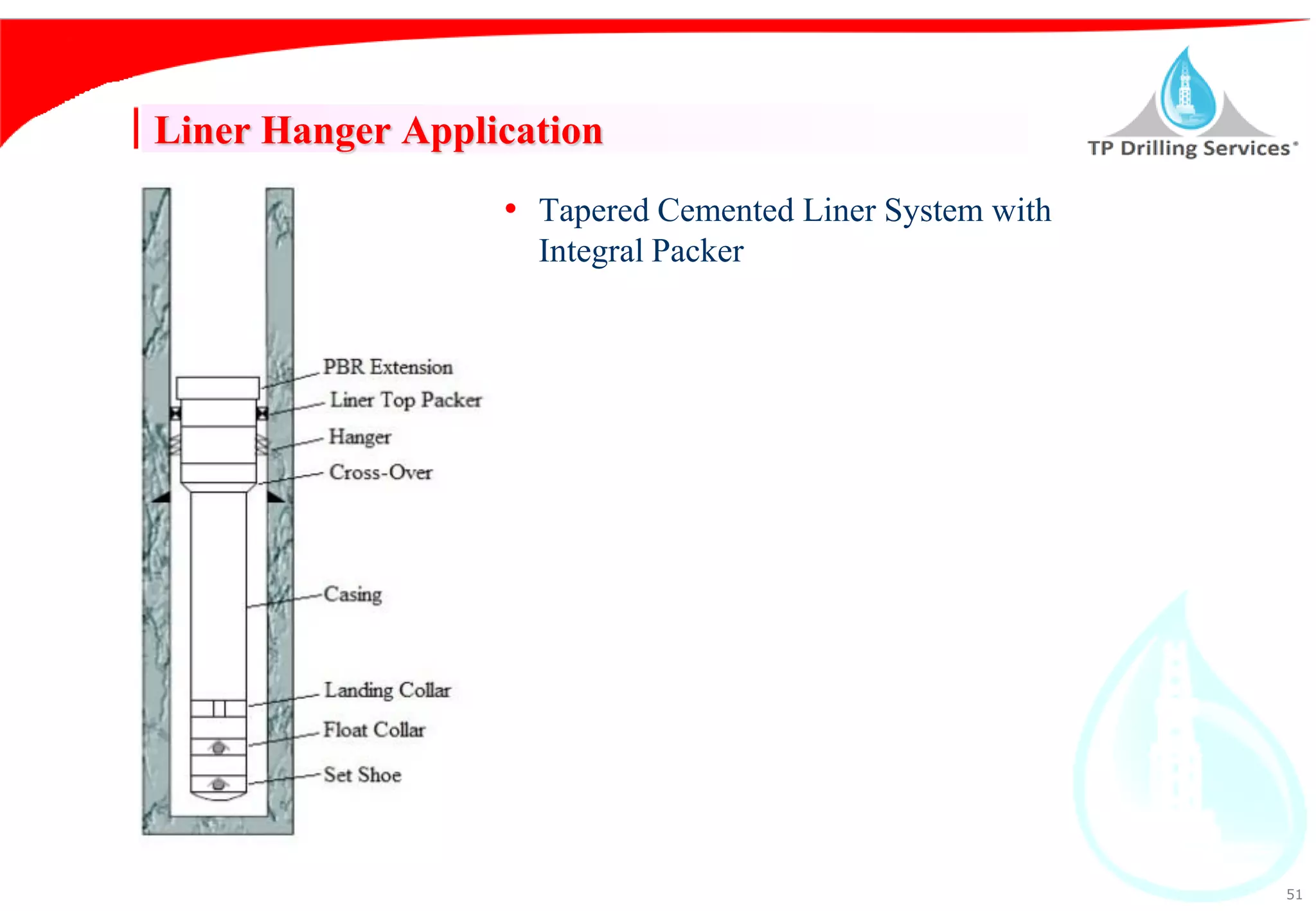

The document outlines the design and operational aspects of liner hangers, including their purpose, various components, and operational procedures. It details the design specifications and ratings for different tools and equipment used in the installation and cementing of liner hangers. Additionally, it provides information on general checklists and specific applications for liner hangers in various well conditions.