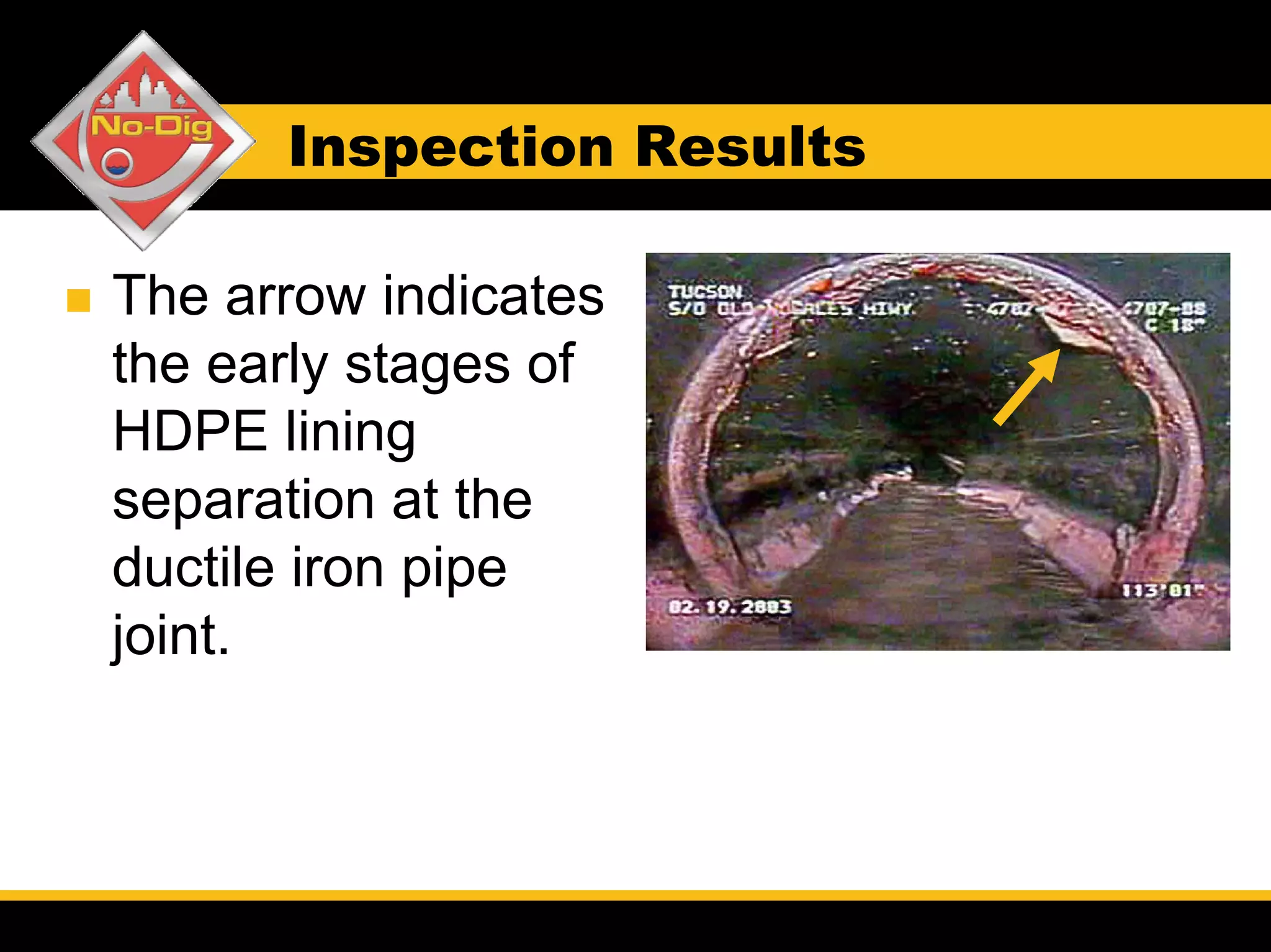

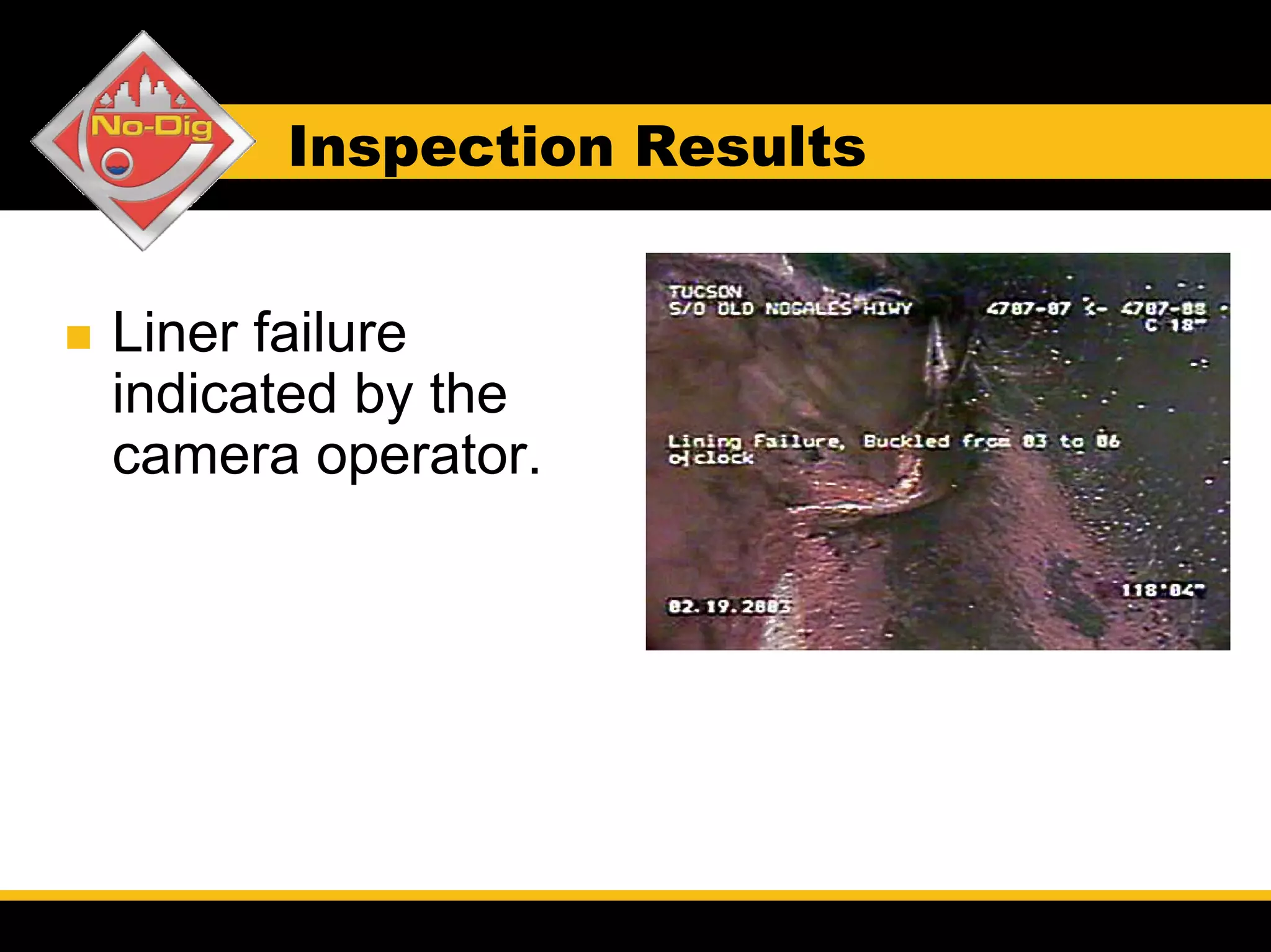

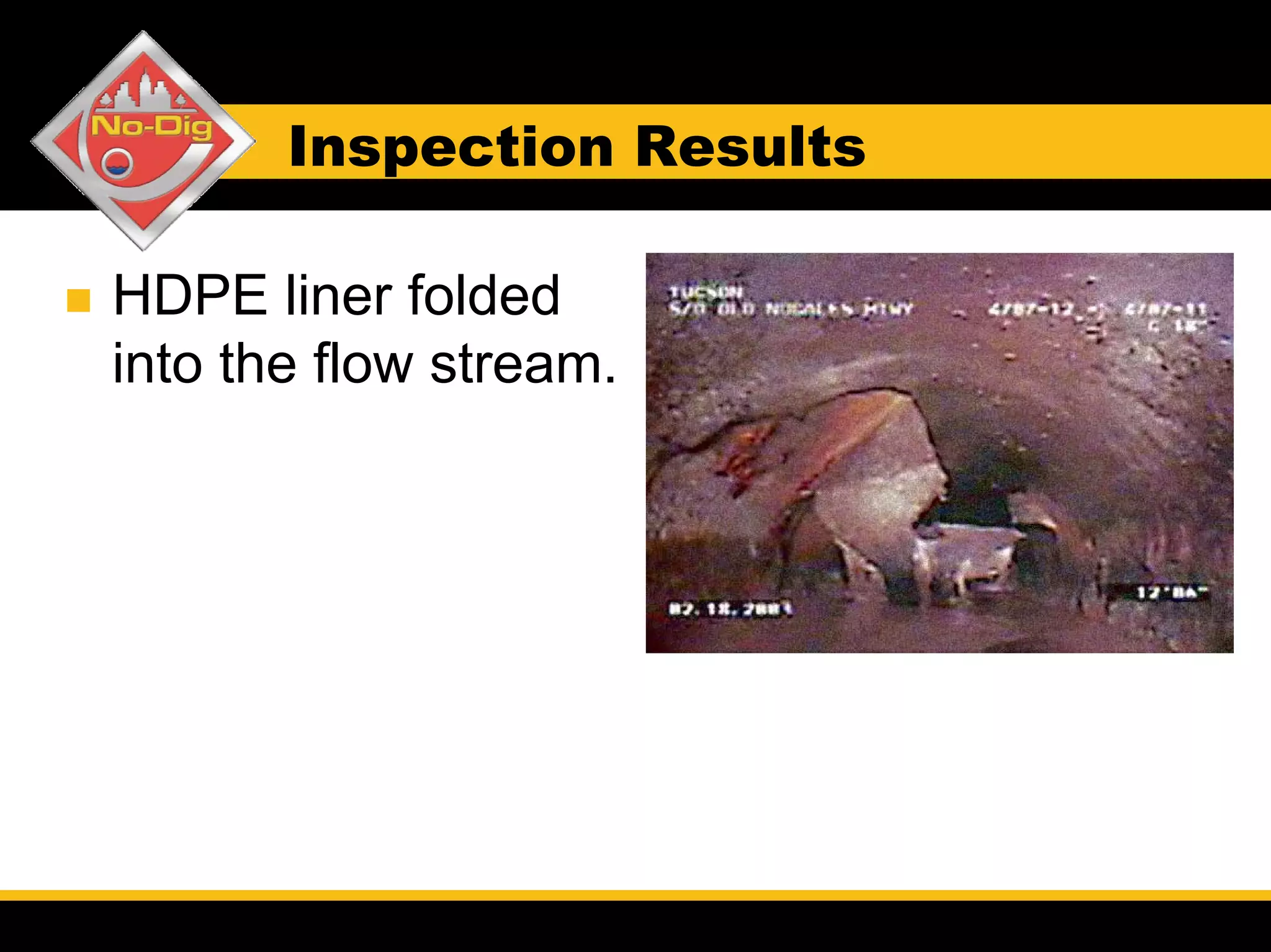

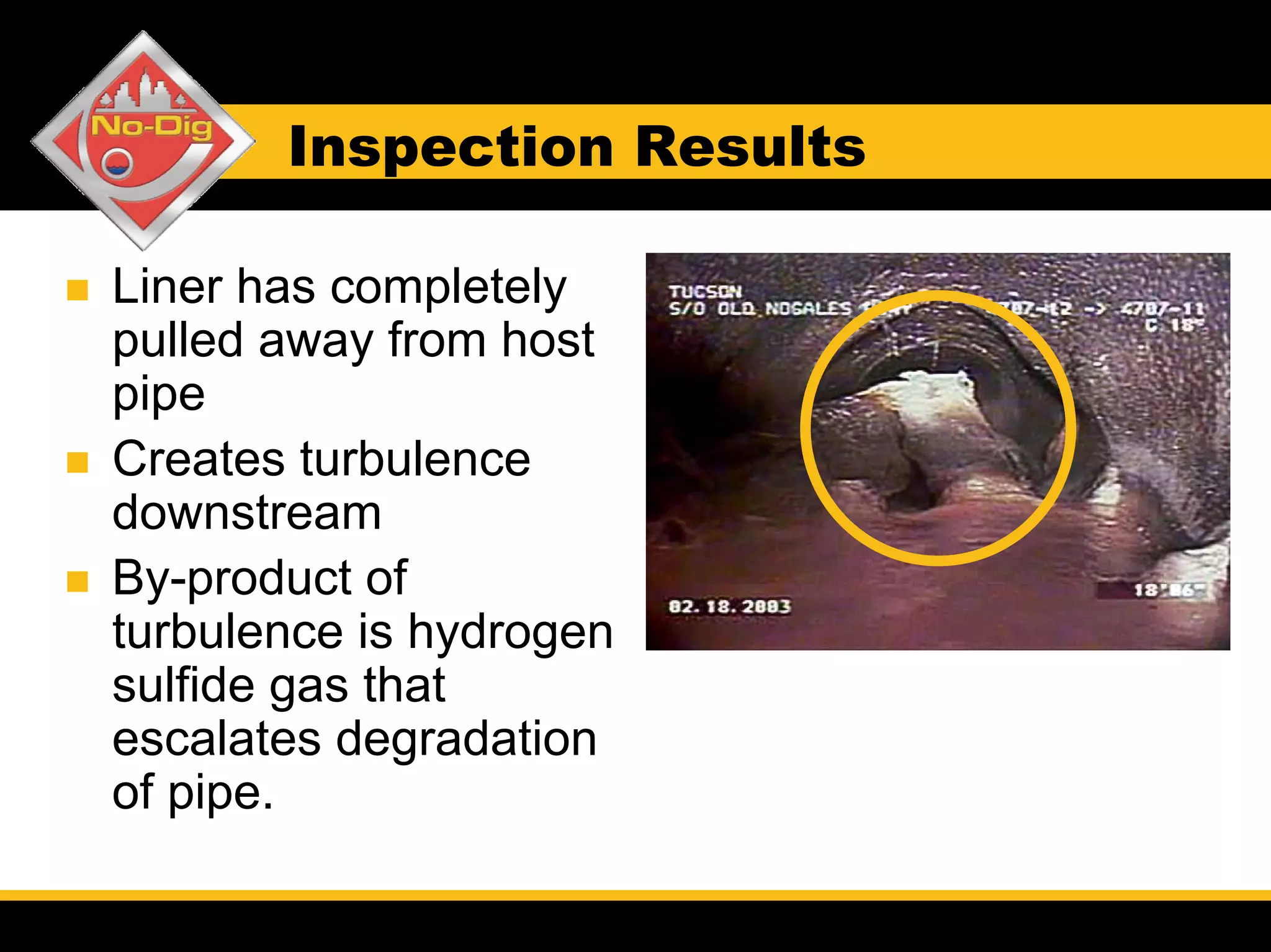

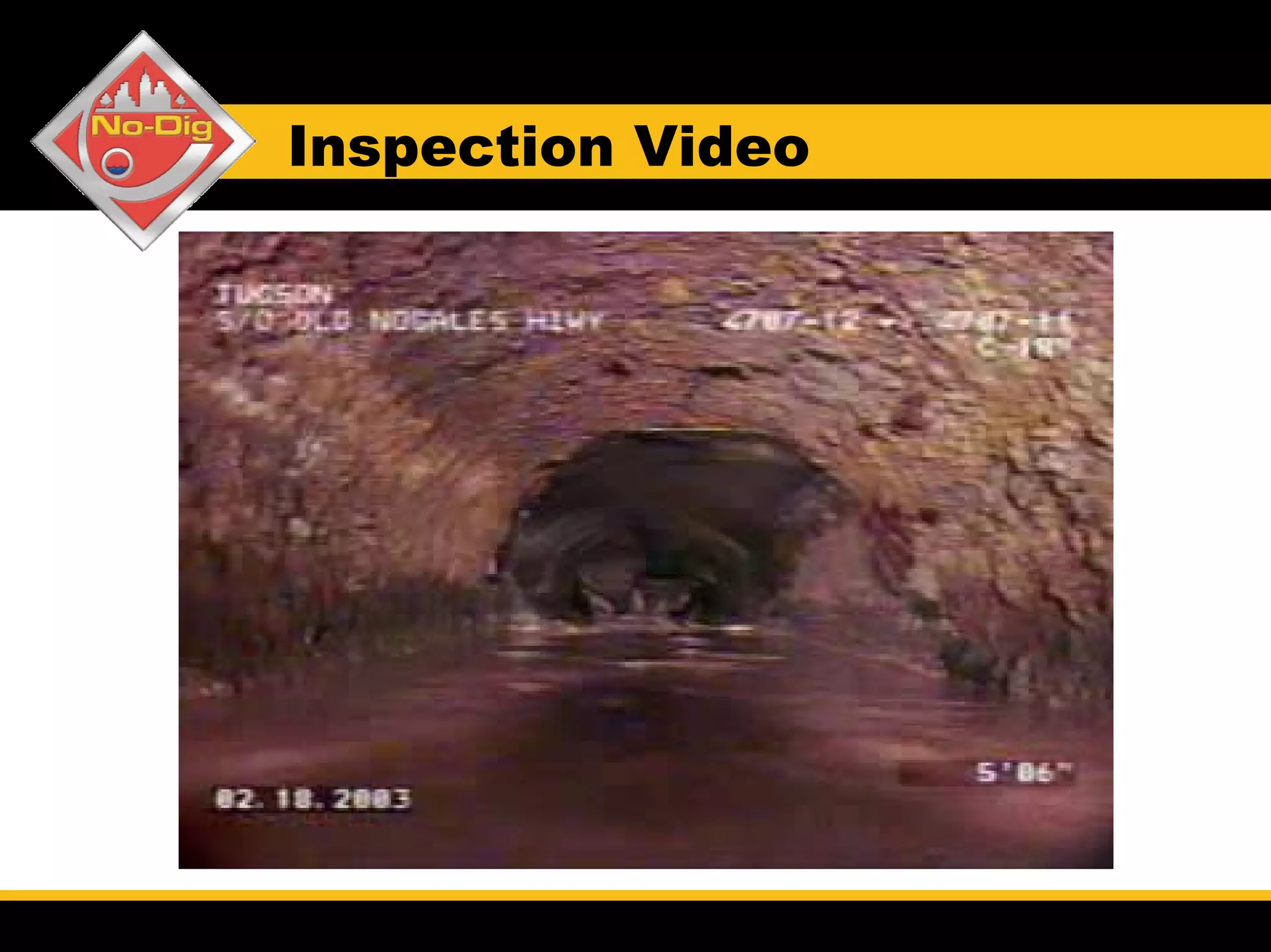

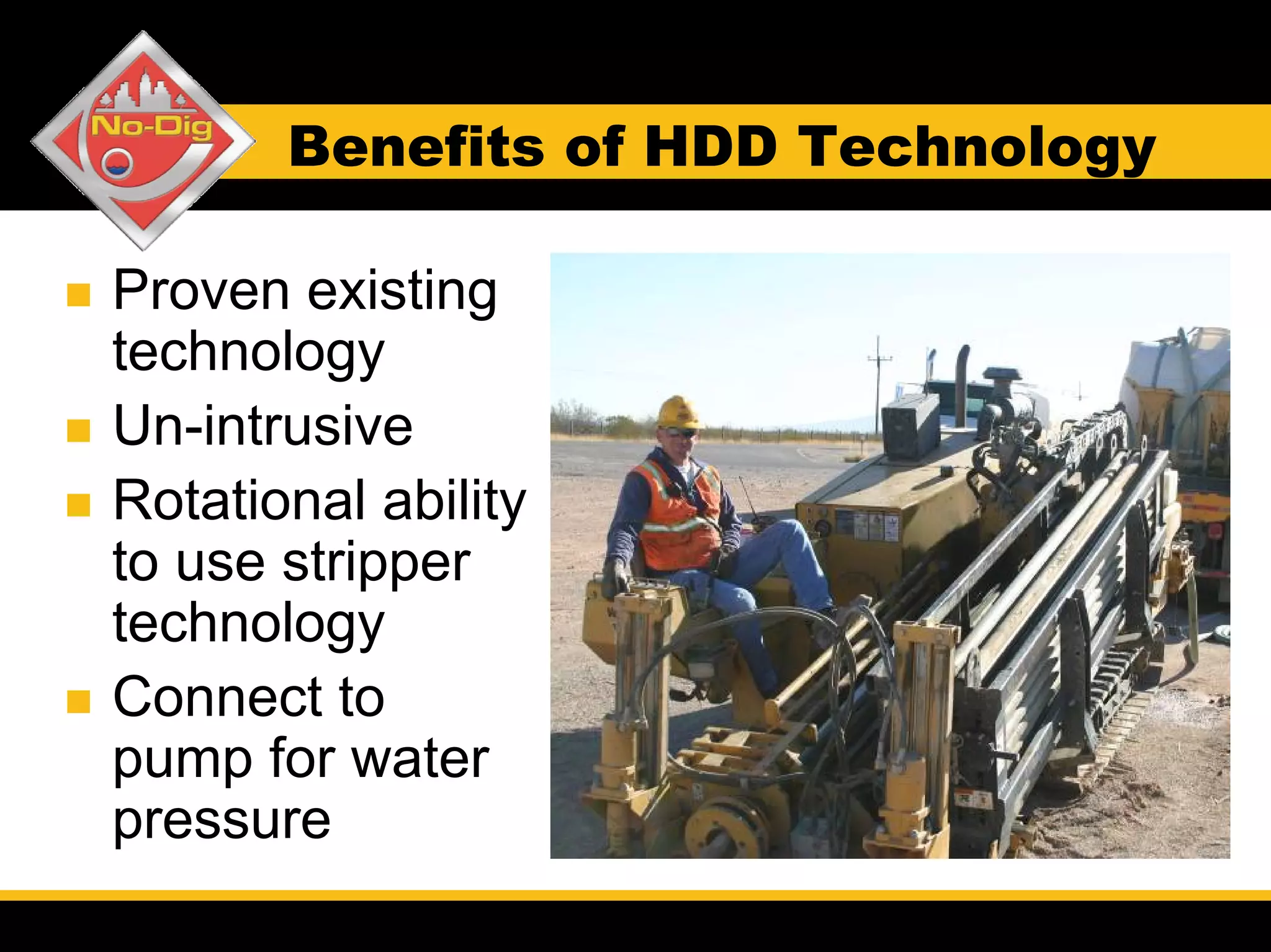

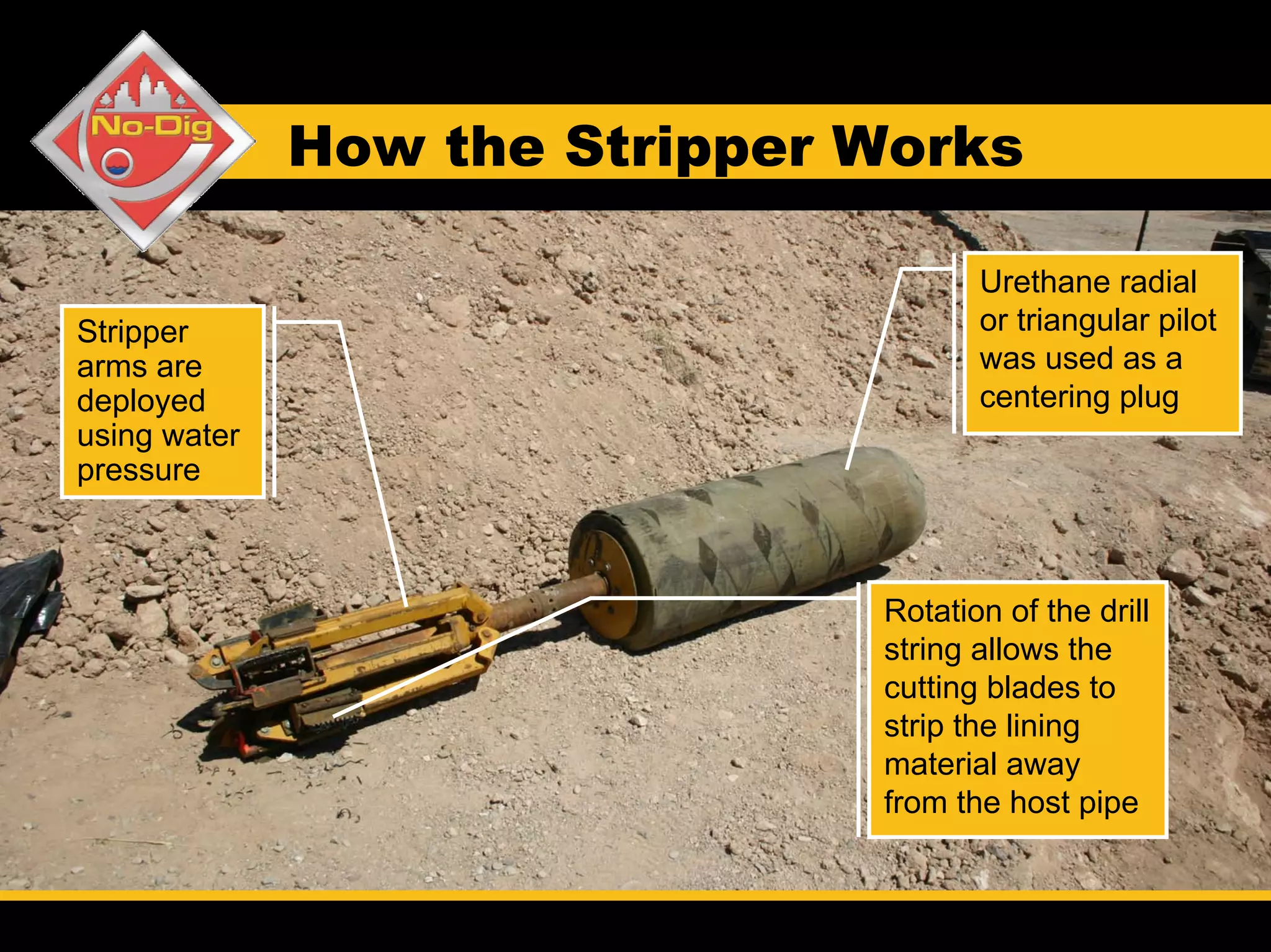

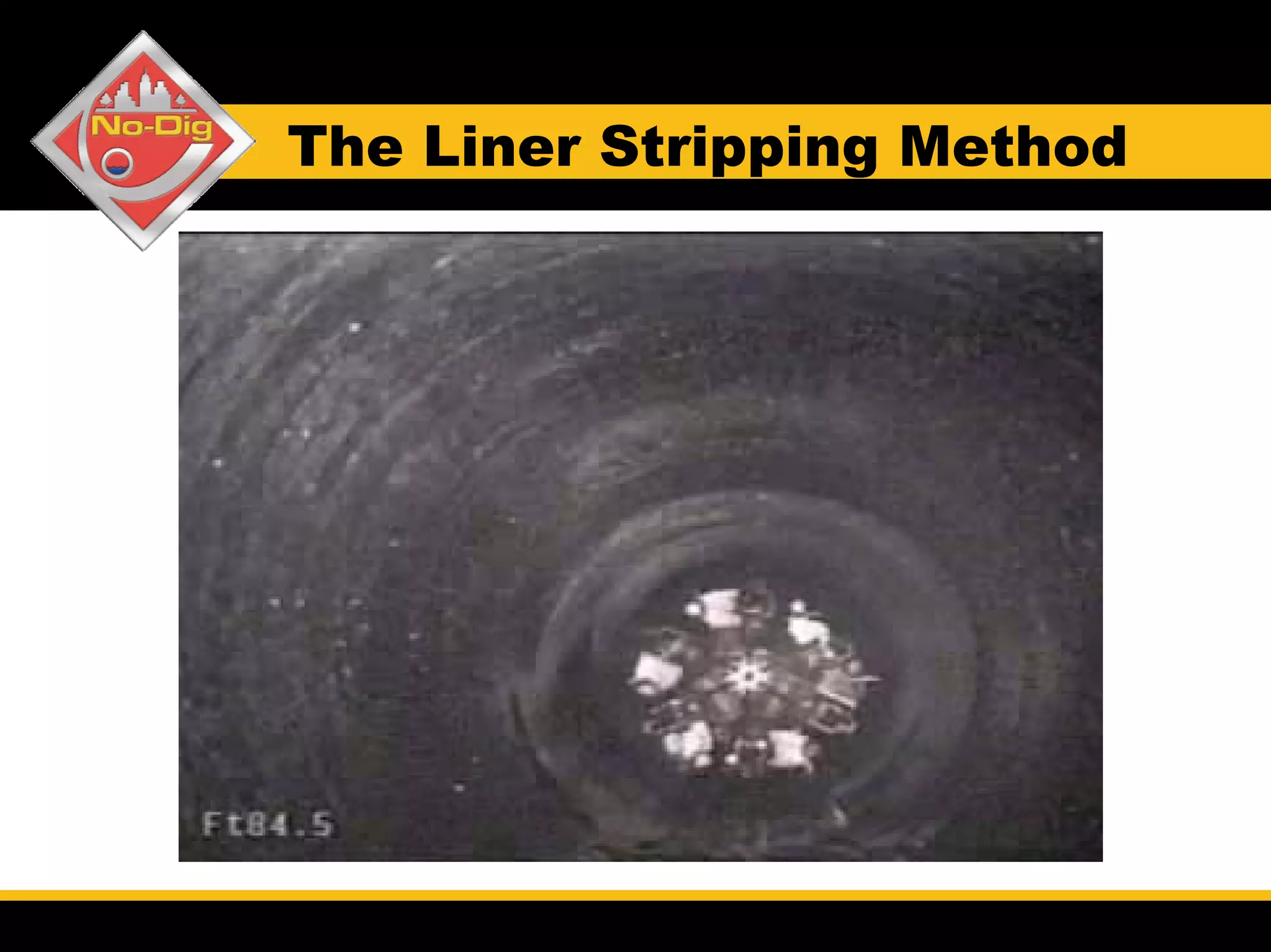

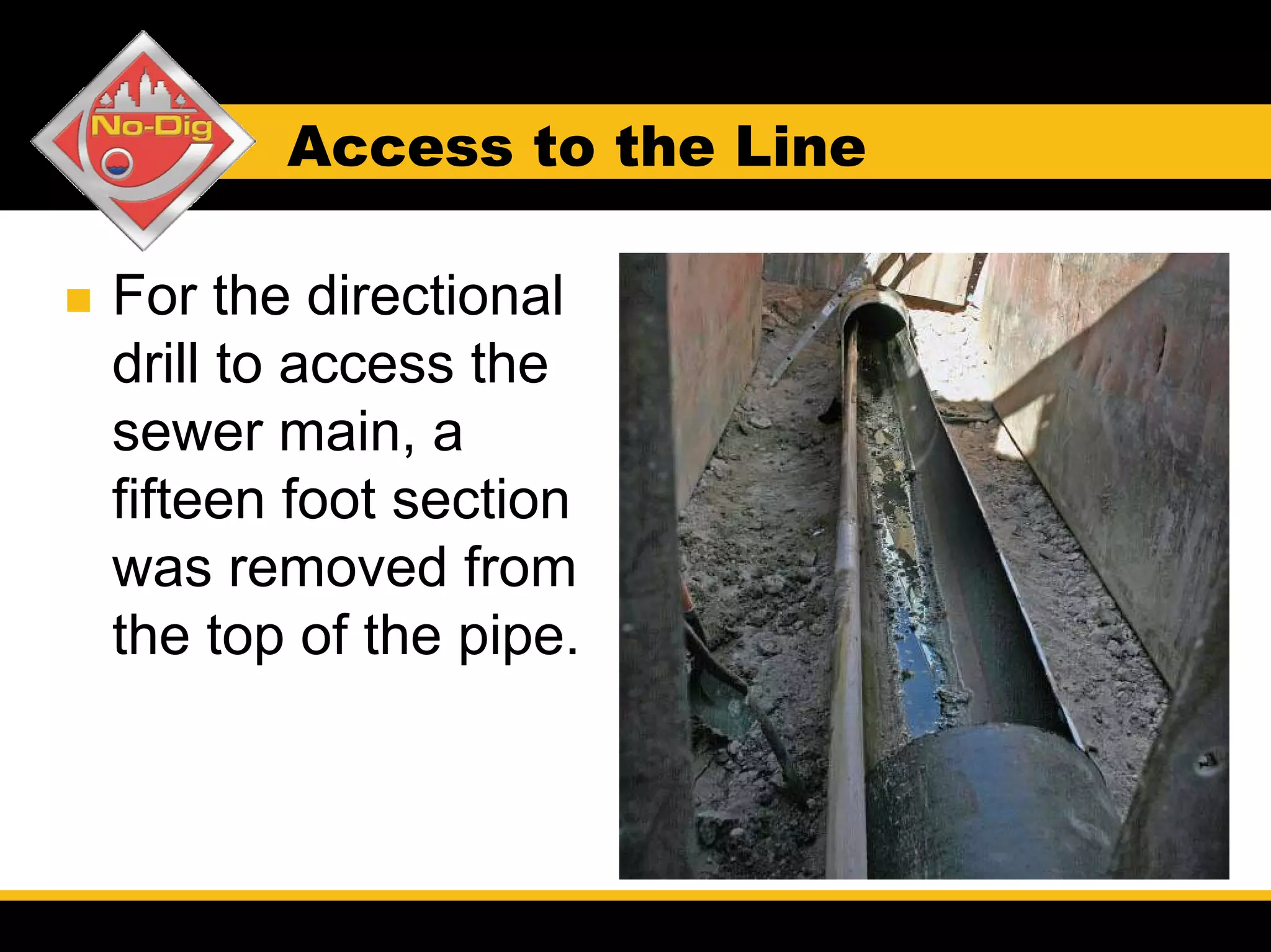

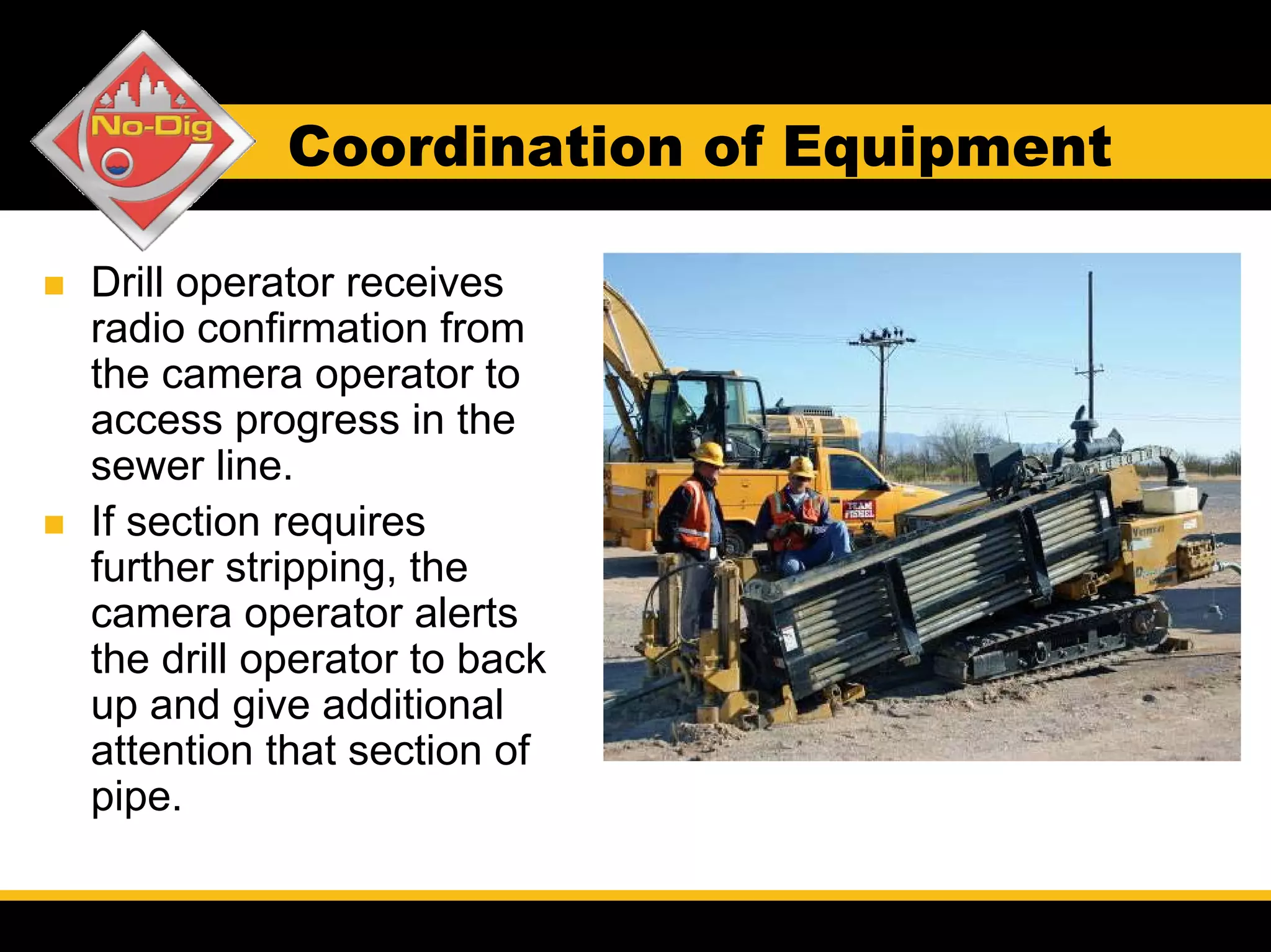

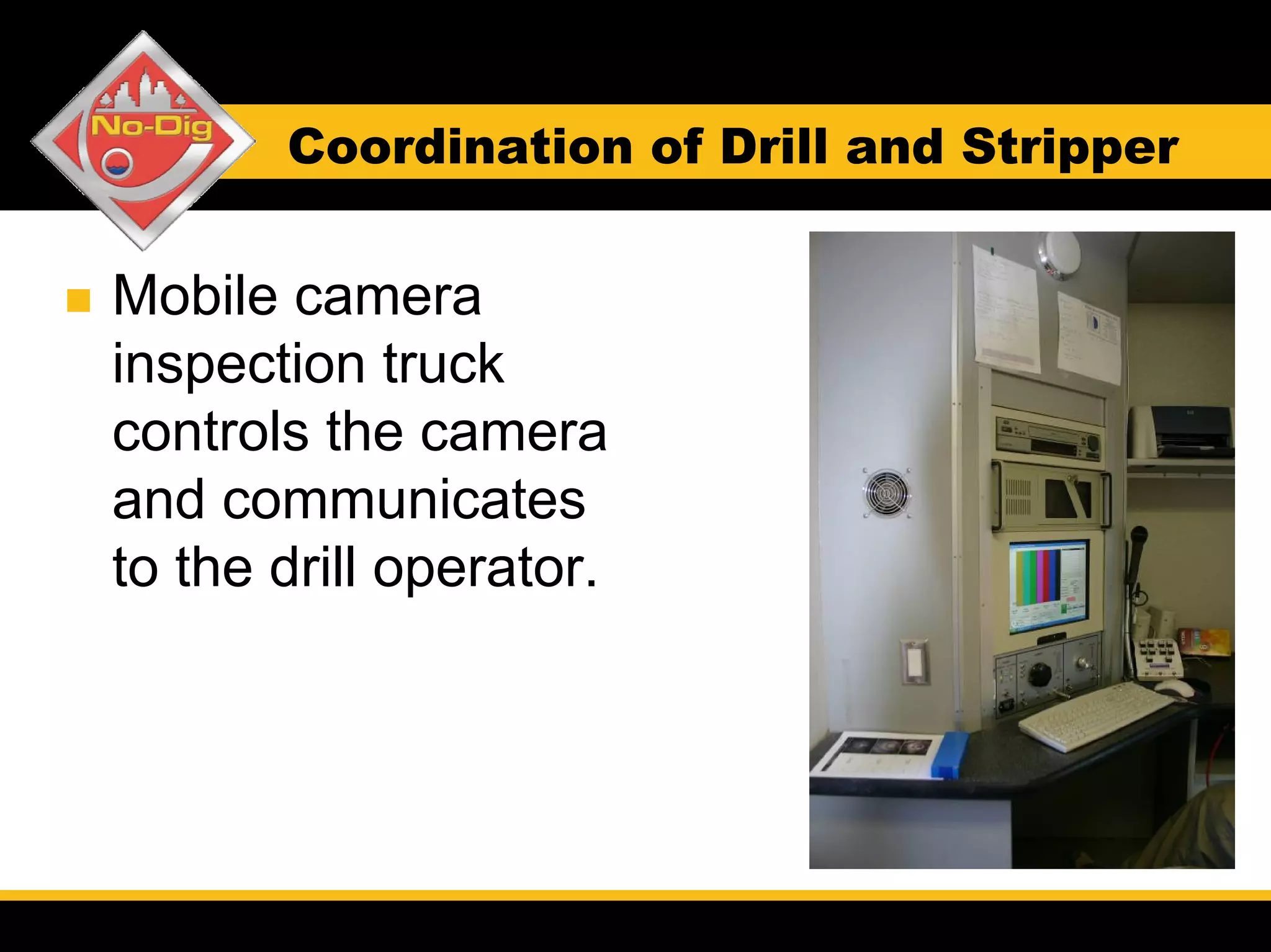

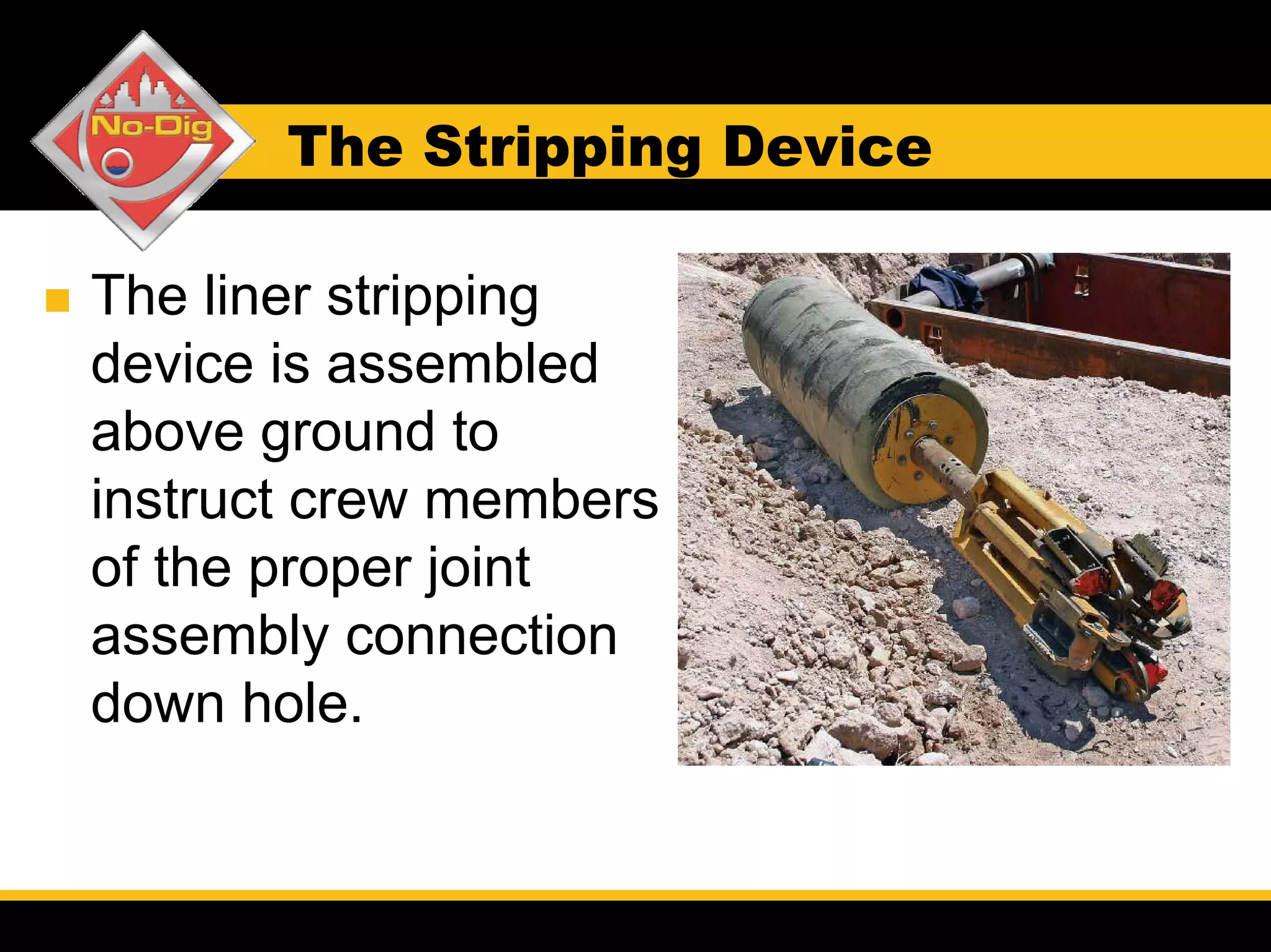

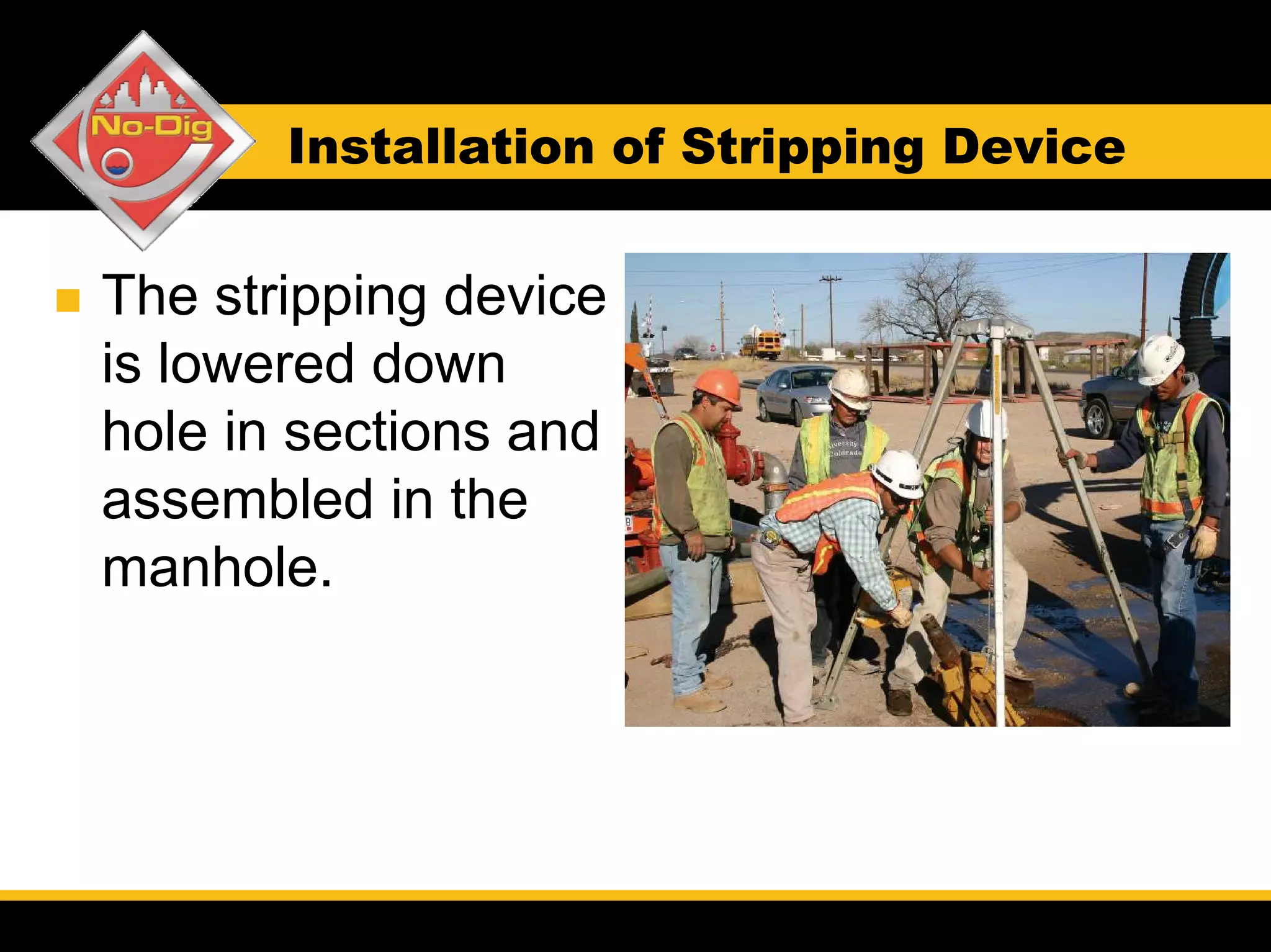

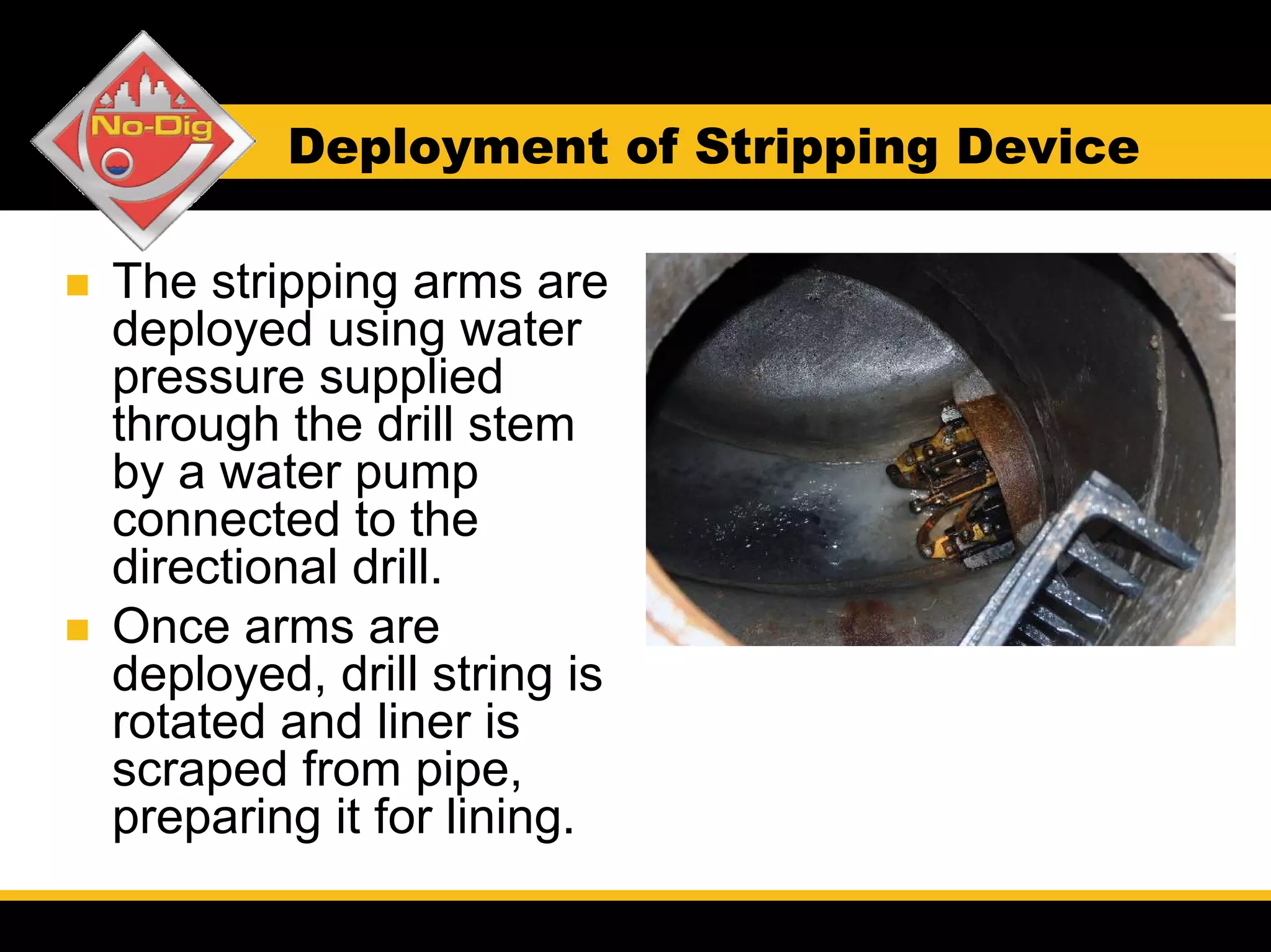

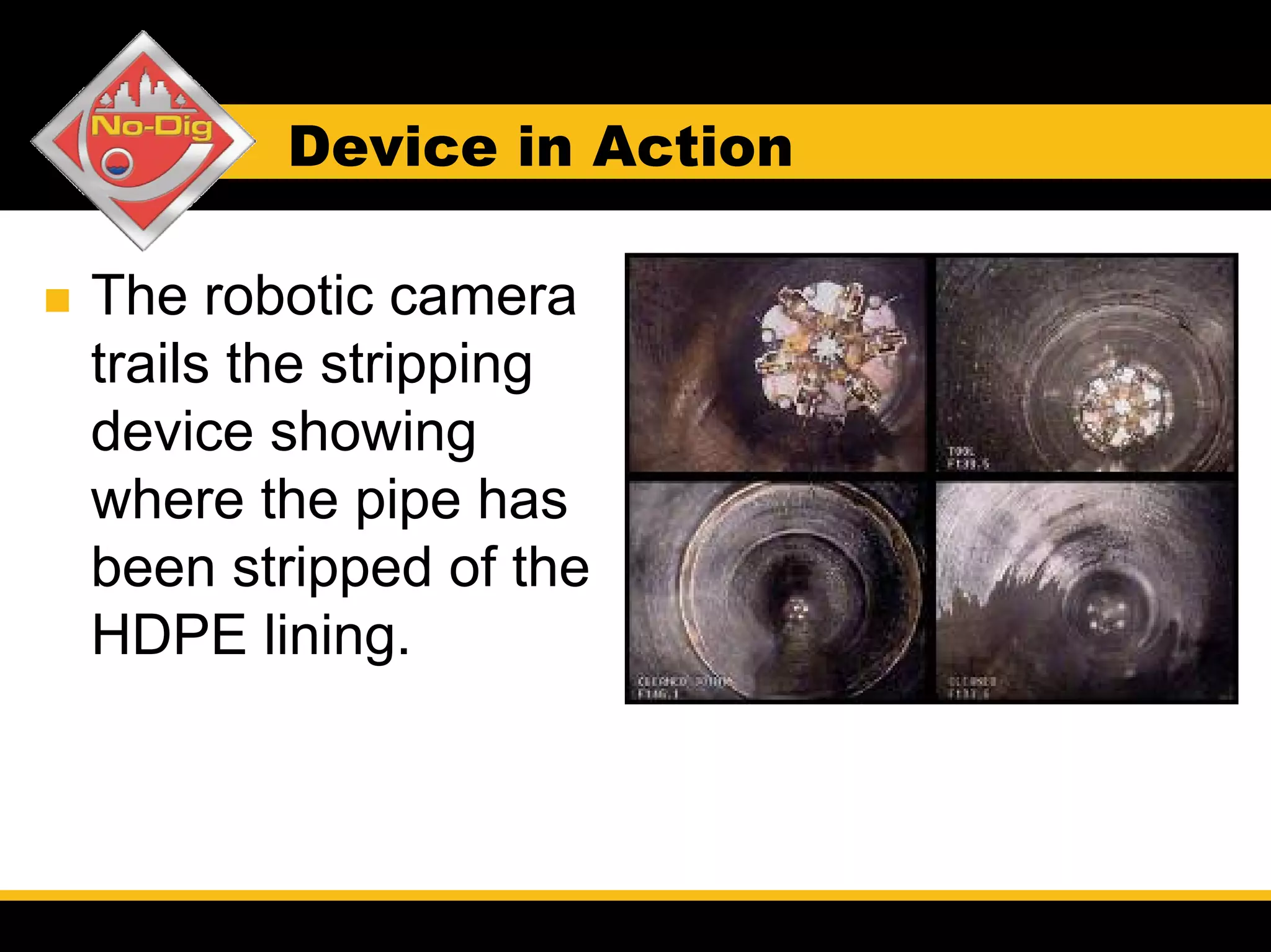

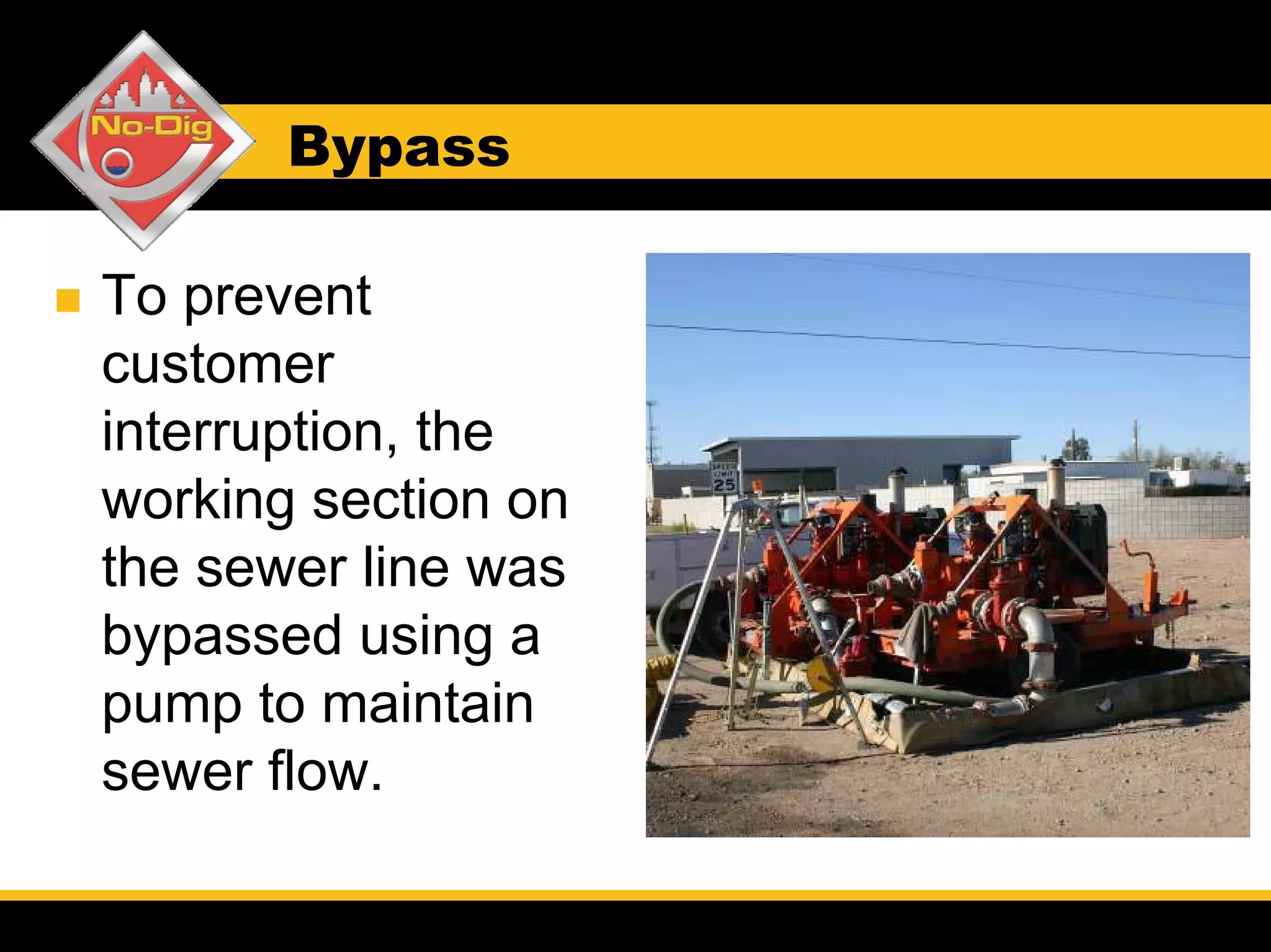

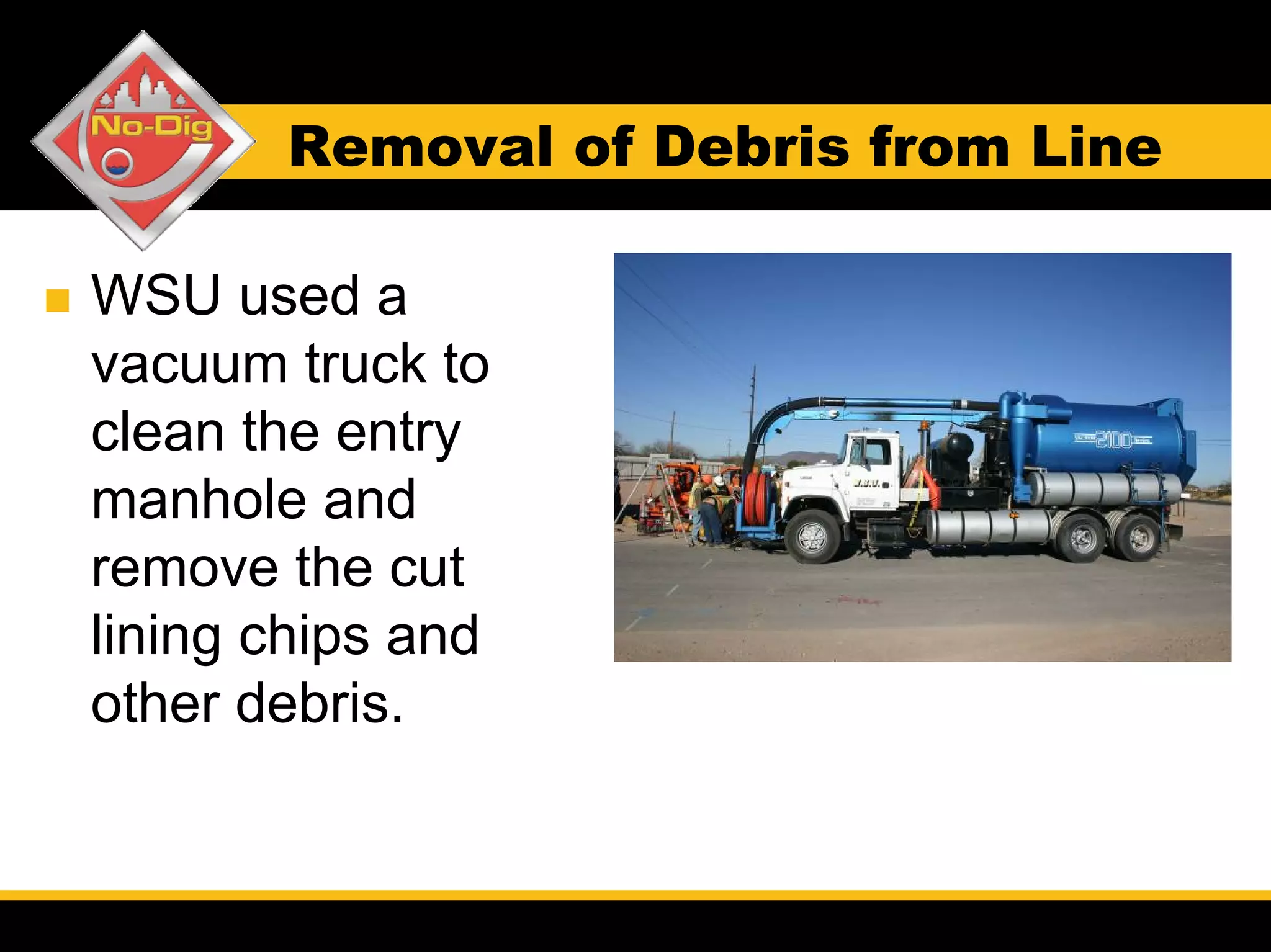

The document discusses the use of HDD technology for stripping de-laminated HDPE liners from pipes, particularly in a Pima County project. It describes the failure of the original HDPE liner due to various factors leading to turbulent flow and associated problems, prompting the development of a new trenchless methodology for efficient removal. The methodology involves a innovative robotic stripping device that prepares pipes for the installation of new liners, resulting in the effective cleaning of approximately 5,700 feet of pipe over two and a half months.