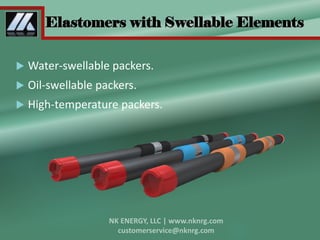

NK Energy Partners has a large network of strategic partners with 450 machines across multiple partner parks. In 2014, partners launched a new test site with proper storage facilities including industrial and warehouse bases. Factories are certified to quality, environmental, and health and safety standards. The company provides equipment and materials for drilling and completion like liner hangers, packers, and centralizers in various diameters for horizontal directional wells. It also produces protectolizers, mandrels, swellable packers, and rubber seals.