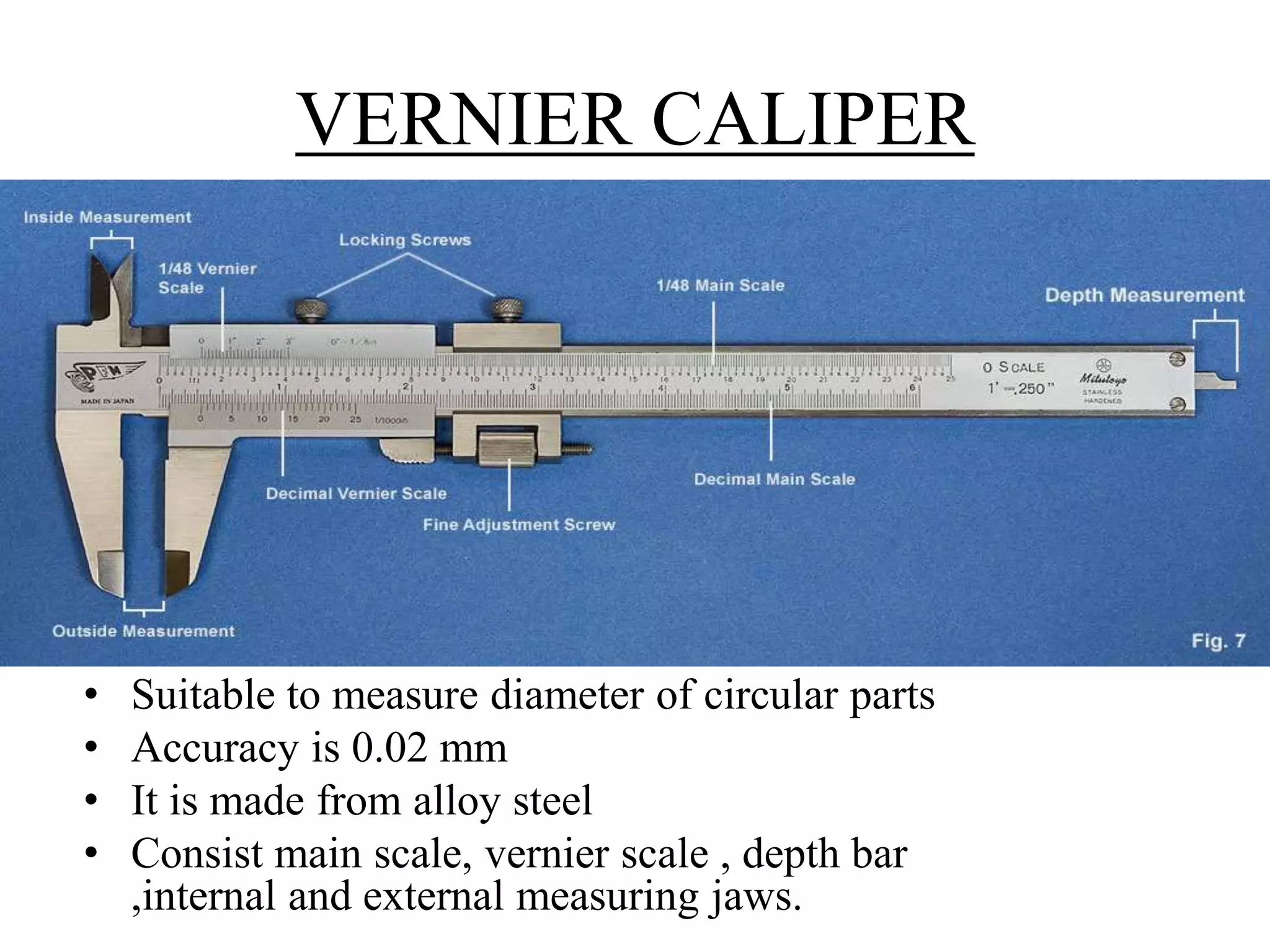

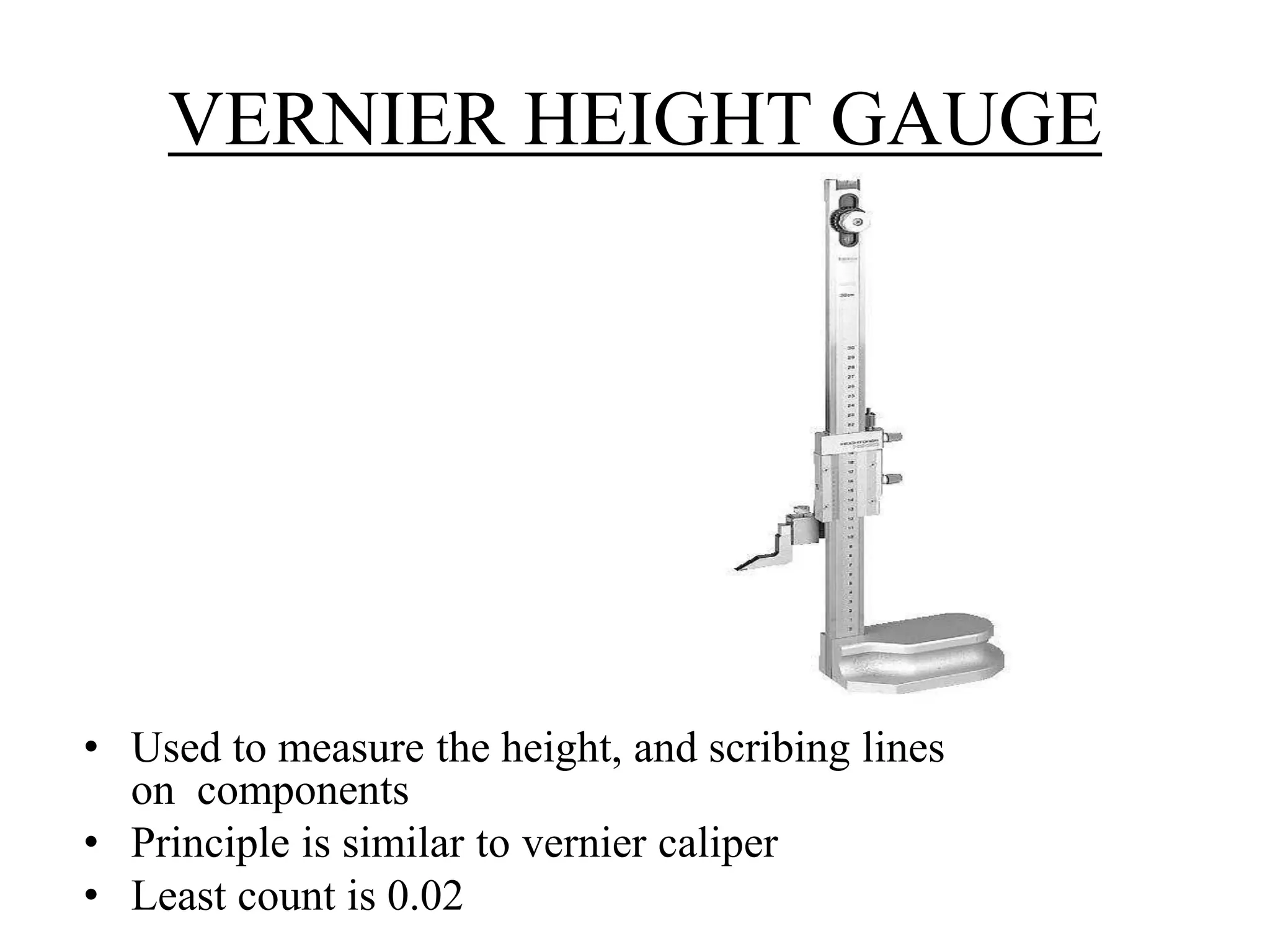

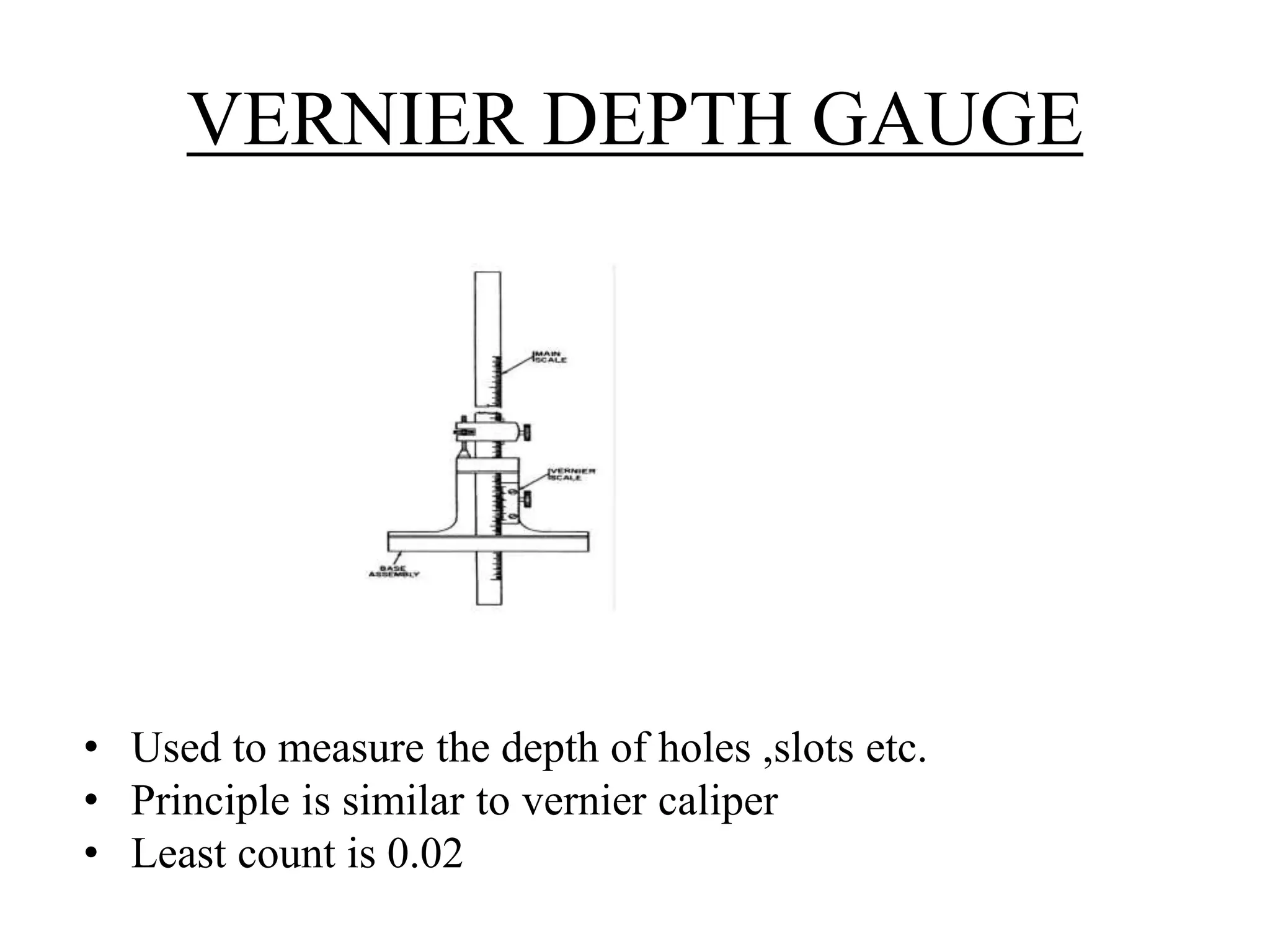

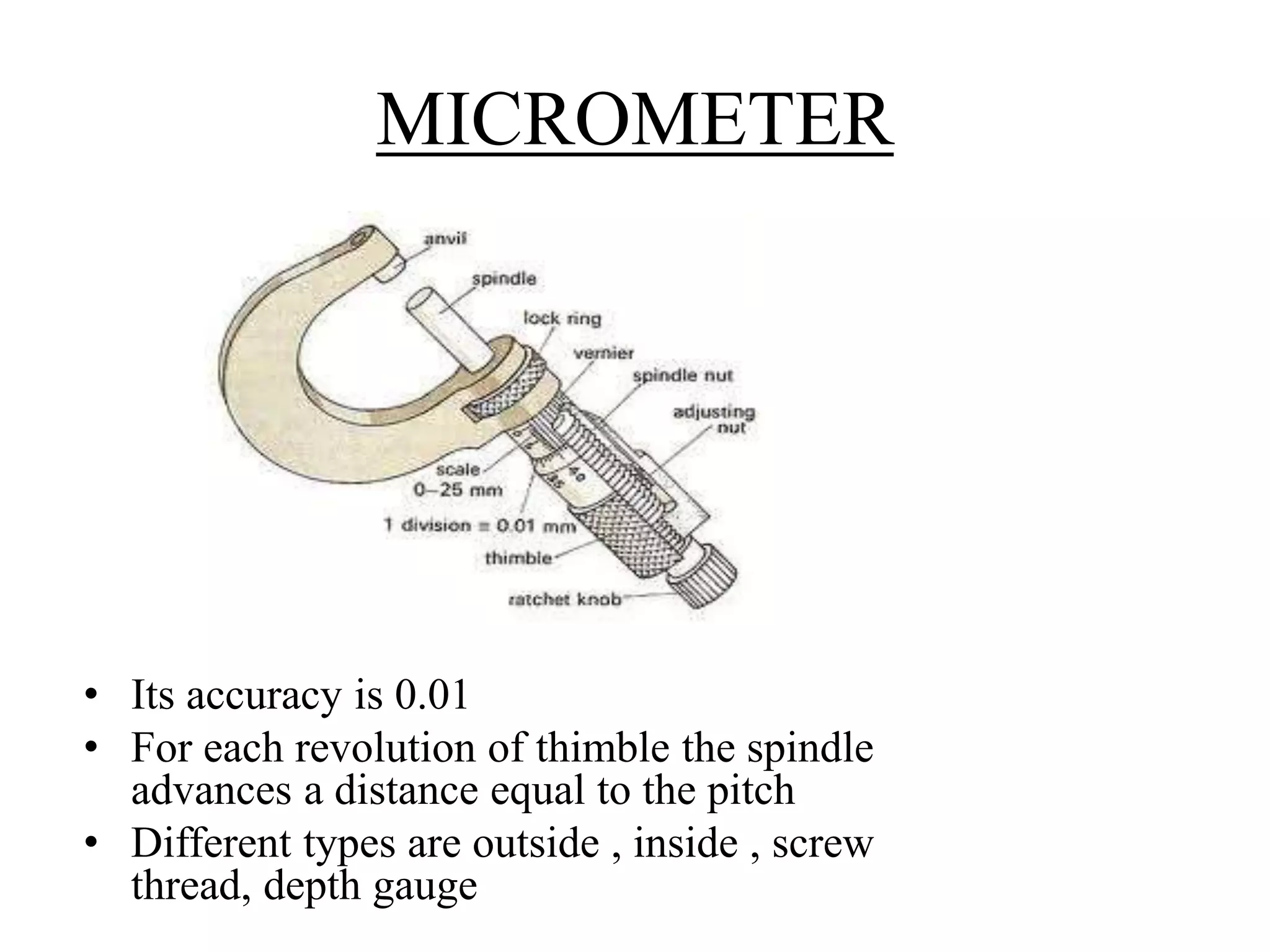

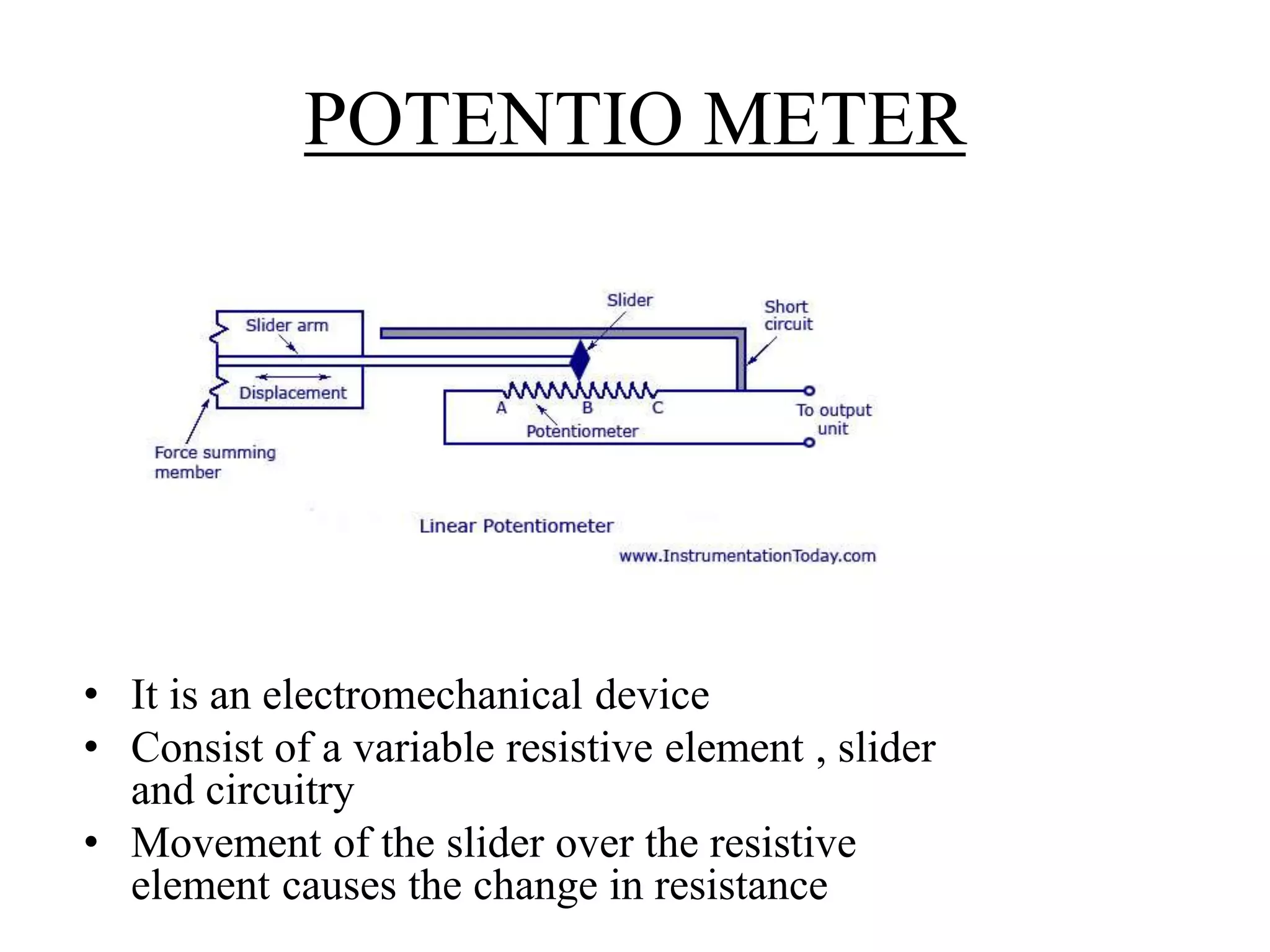

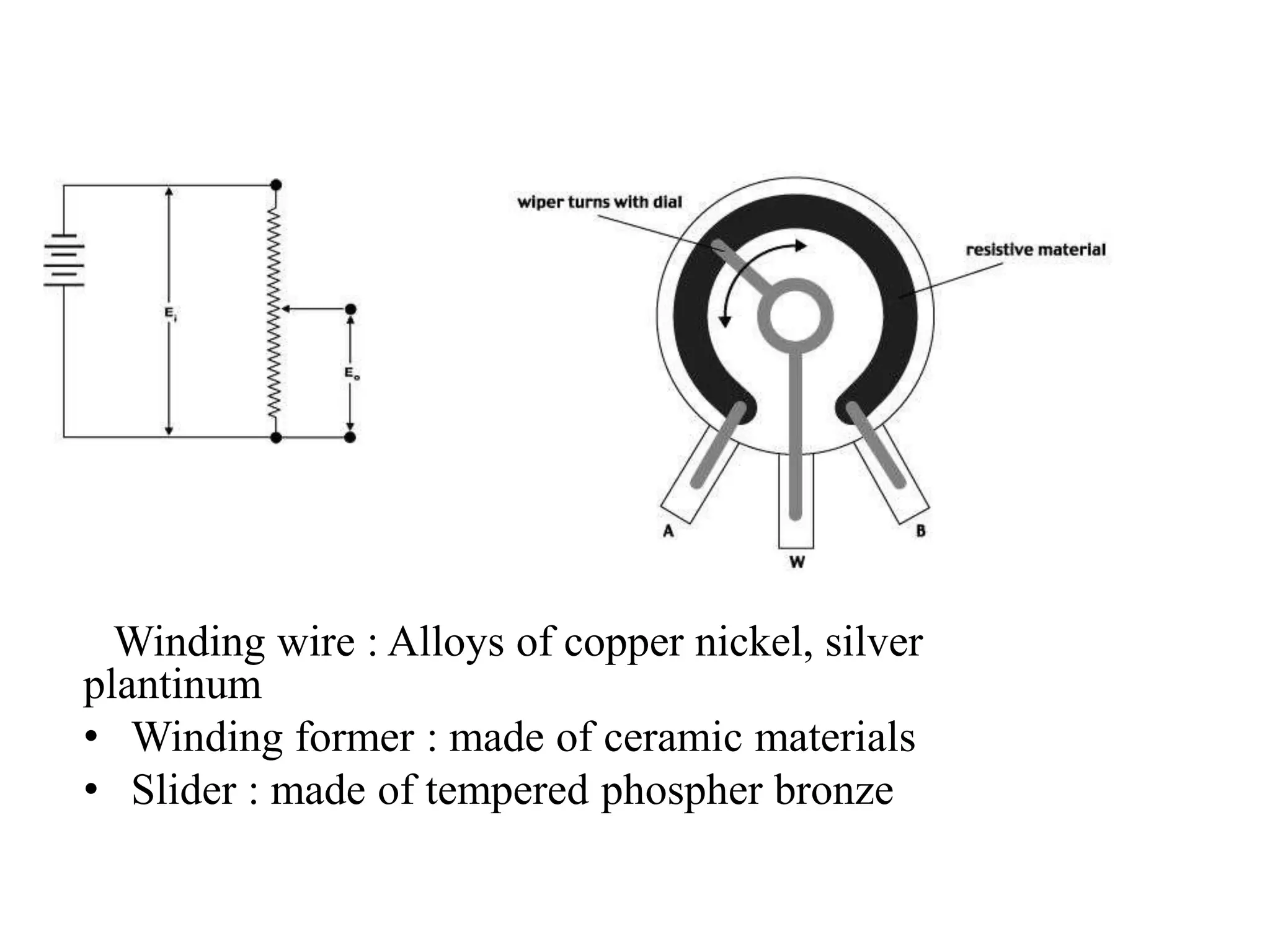

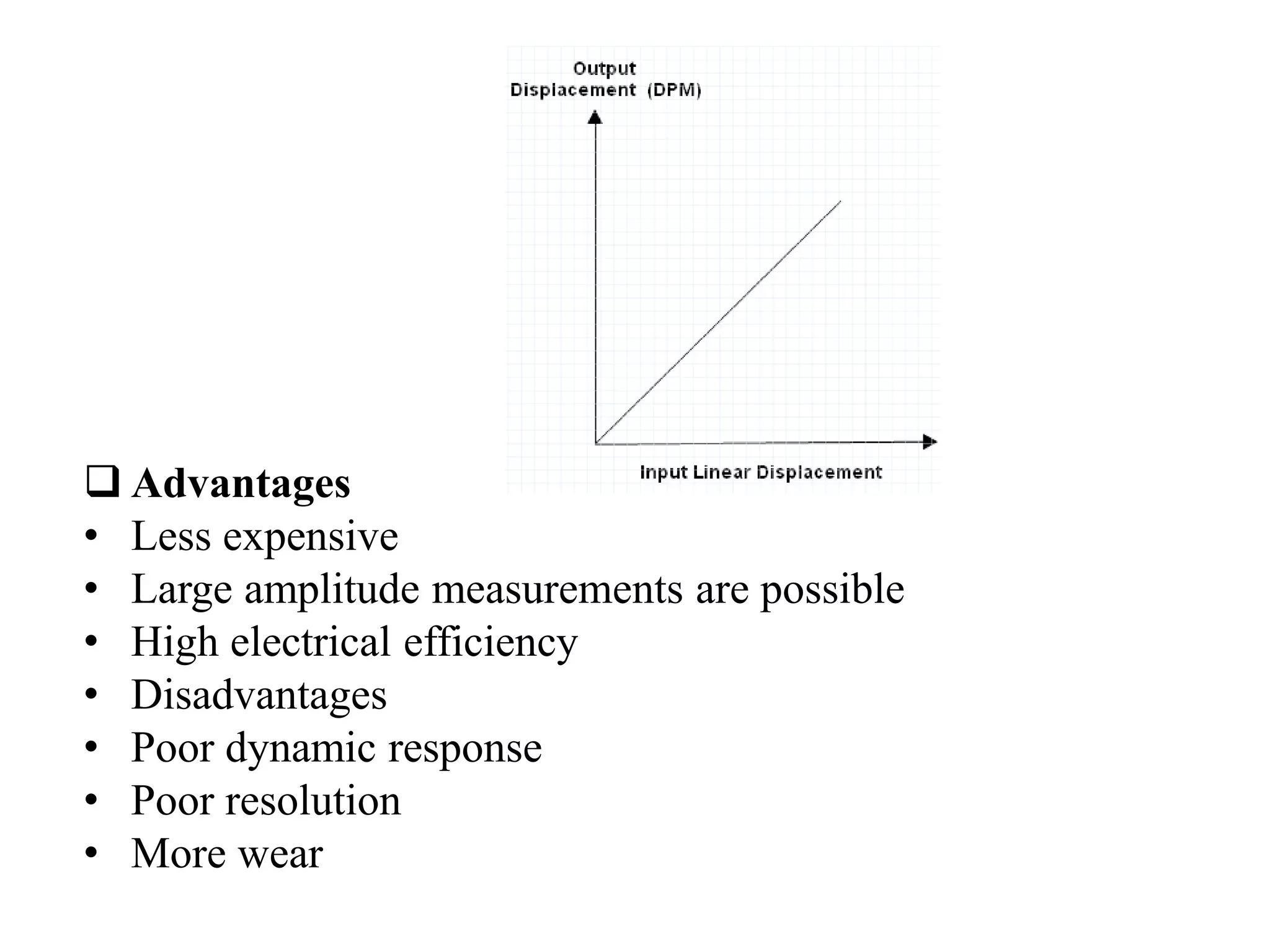

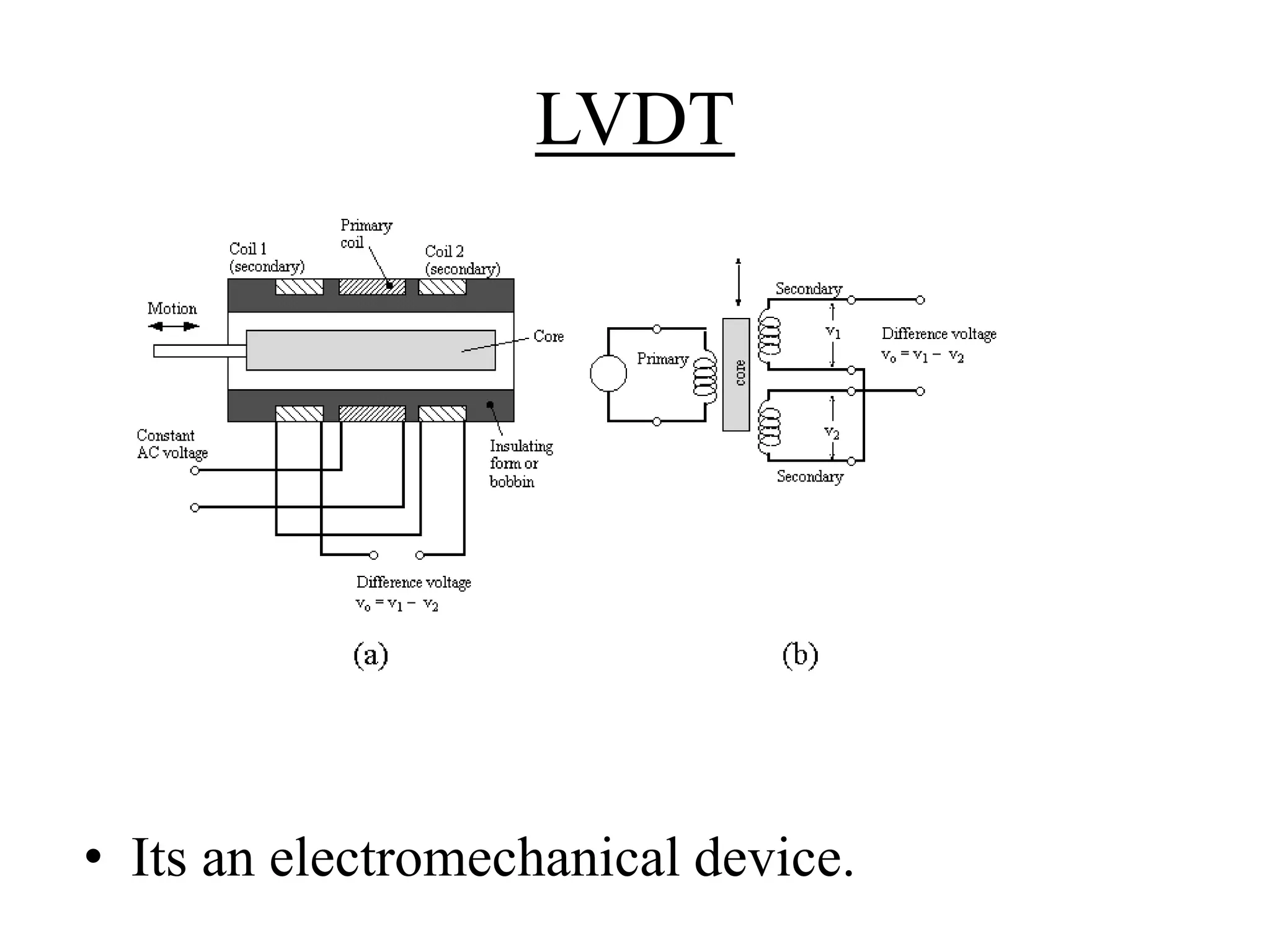

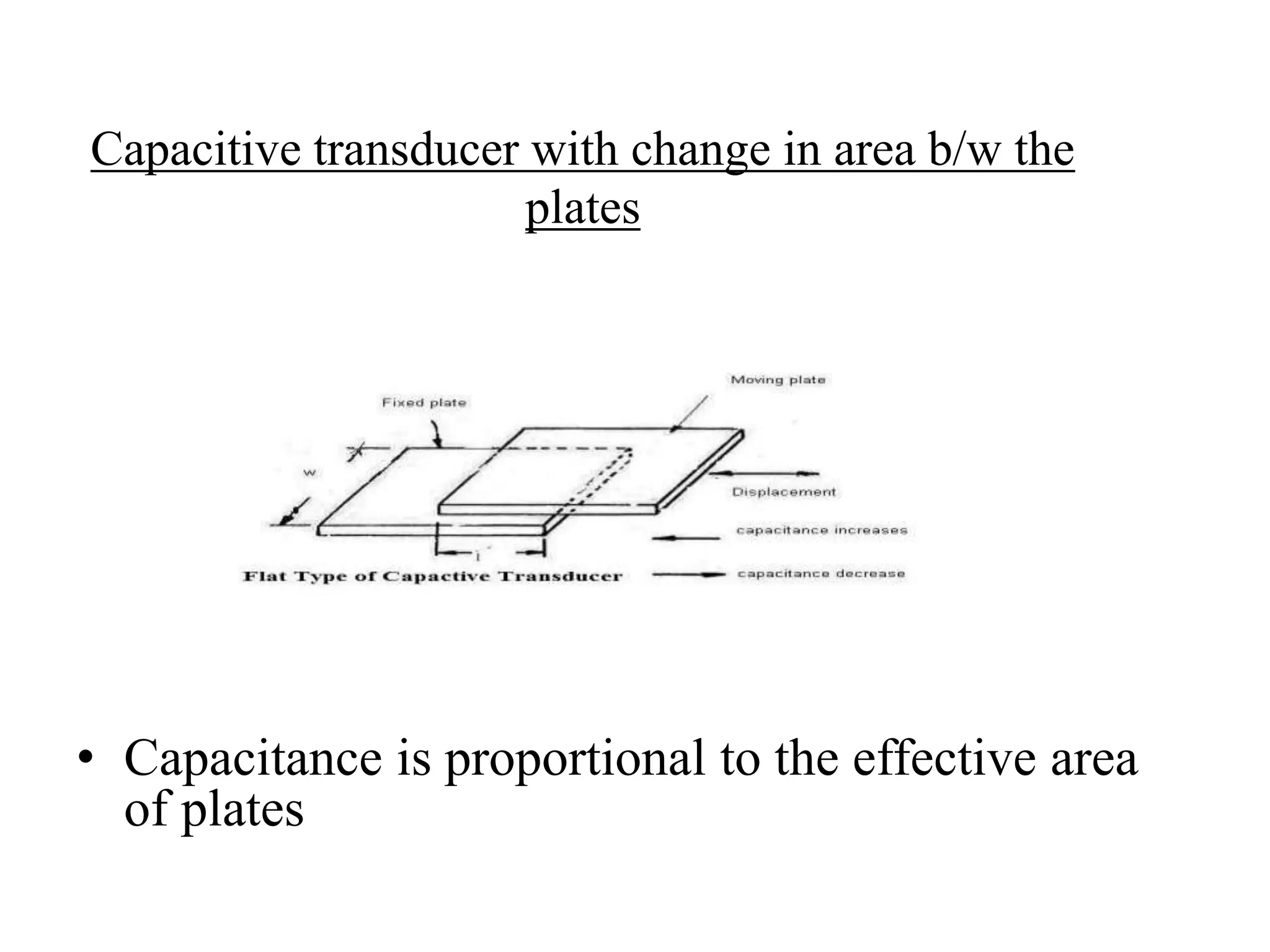

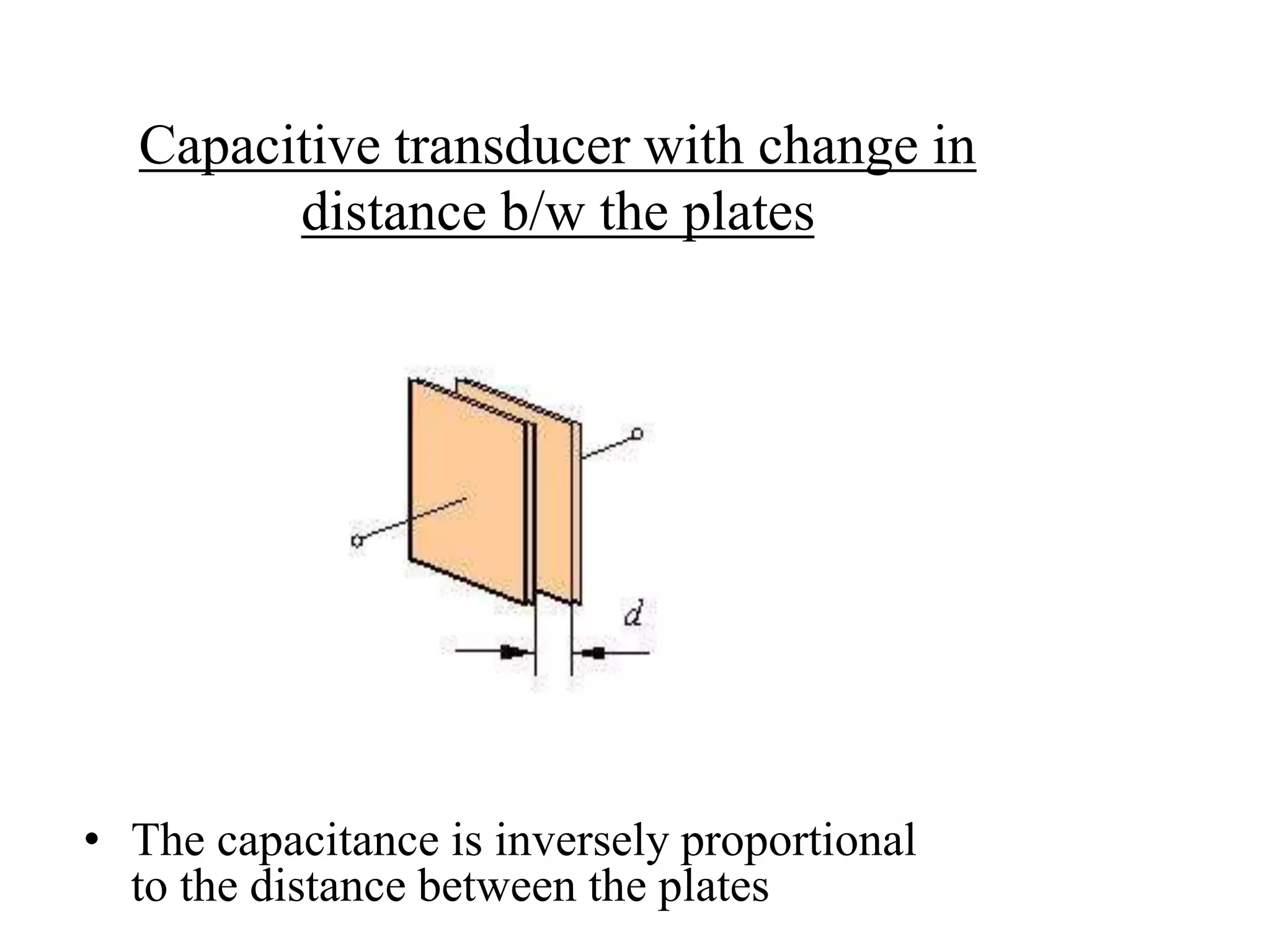

This document discusses various tools used for linear measurement. It describes steel rules, vernier calipers, micrometers, and other tools that can directly measure length, diameter, thickness and other linear dimensions. It also discusses transducers that convert linear displacement into an electrical signal, including linear variable differential transformers (LVDTs) and capacitive transducers. LVDTs and capacitive transducers allow linear measurements to be monitored electronically.