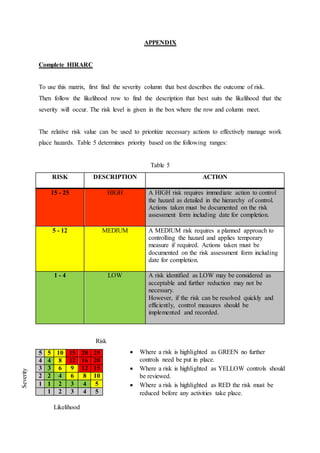

Where a risk is highlighted as GREEN no further controls need be put in place. Where a risk is highlighted as YELLOW controls should be reviewed. Where a risk is highlighted as RED the risk must be reduced before any activities take place. The document then provides tables to assess risk based on severity and likelihood, and determines if the risk is low, medium, or high. It provides actions required based on these risk levels.