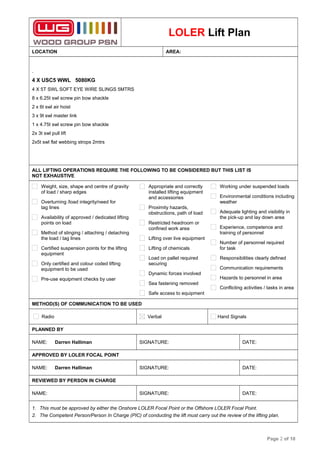

This LOLER lift plan details the steps for installing Mod 9 PA SDV-20253 valves. It involves pre-rigging lifting points and slinging the 3000kg load. The valves will be lifted using 4 air hoists and soft eye wire slings, transferred across structure, and lowered into position. Riggers will follow safety procedures like using harnesses, erecting barriers, and inspecting equipment. The lift requires multiple personnel and will be supervised by a rigging foreman.