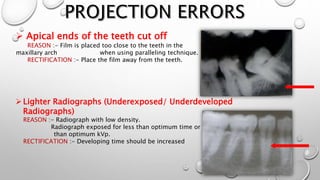

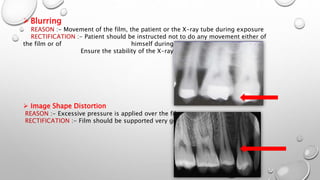

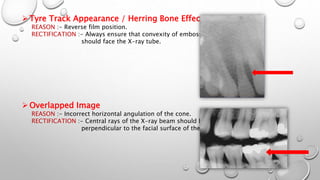

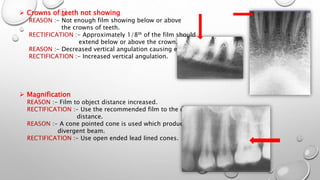

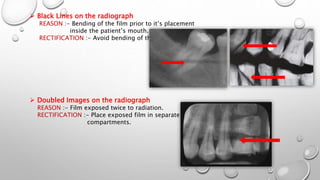

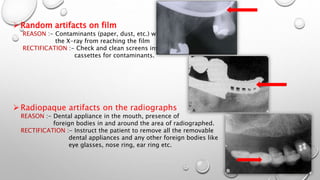

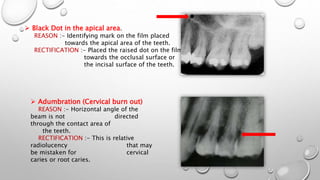

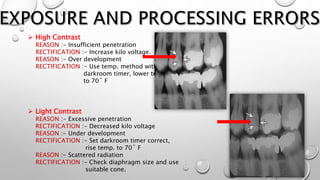

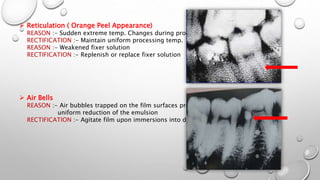

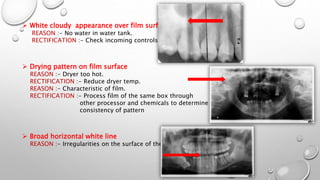

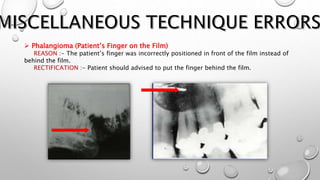

This document discusses common causes and remedies for faulty radiographs. It identifies projection errors, exposure and processing errors, automatic processing errors, and miscellaneous technique errors as broad categories of causes. It then provides specific examples of common errors like apical ends cut off, lighter or darker films, cone cuts, blurring, distortions, overlapped images, magnification errors, and artifacts. For each error, it describes the likely reason and provides recommendations for rectification. The document serves as a guide for identifying and addressing issues that can arise during the x-ray taking and processing stages.