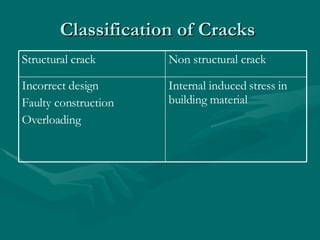

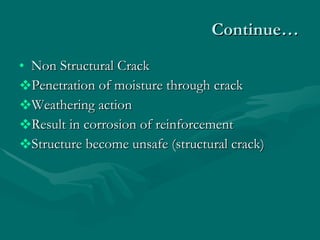

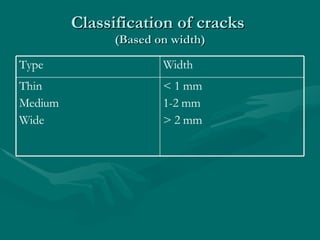

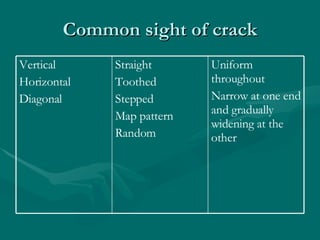

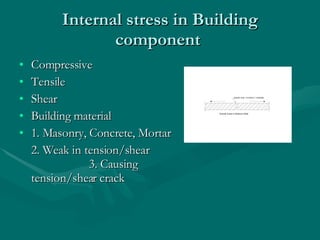

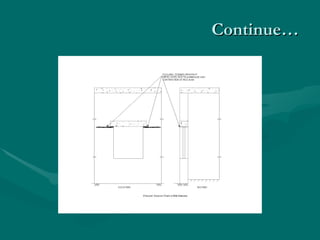

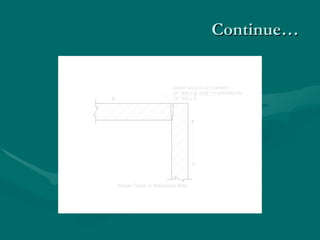

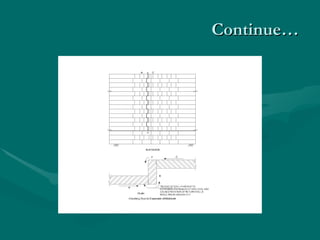

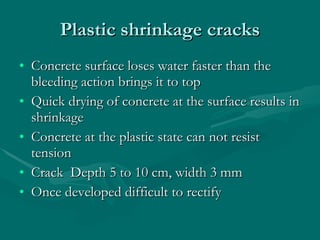

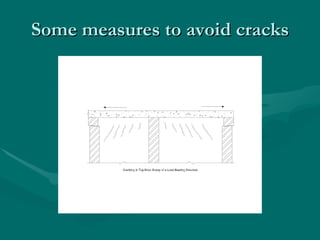

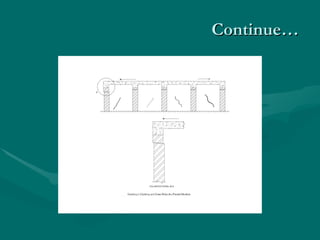

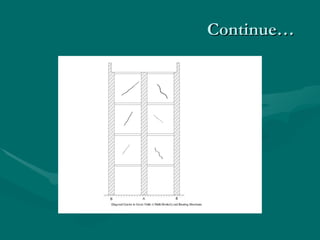

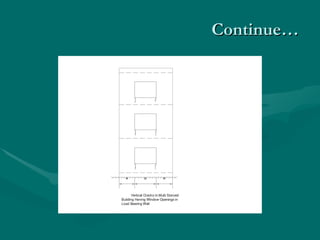

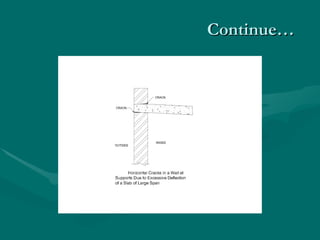

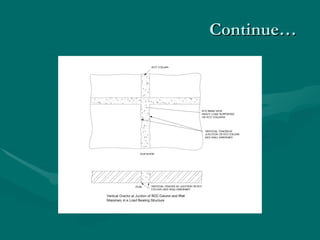

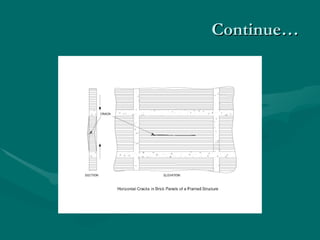

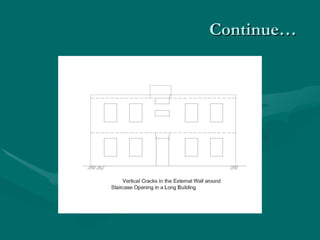

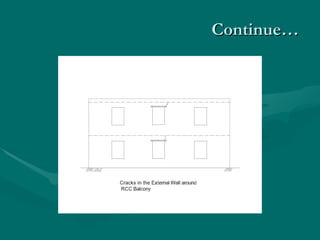

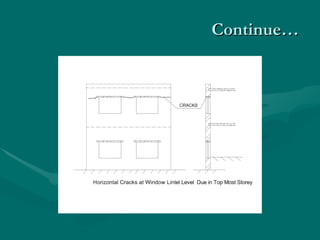

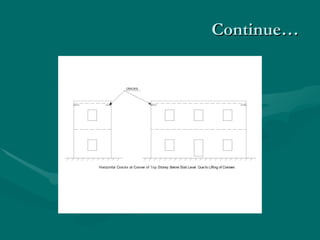

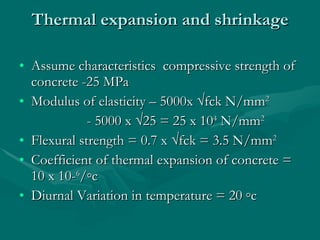

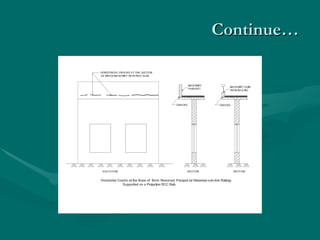

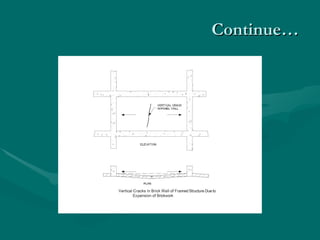

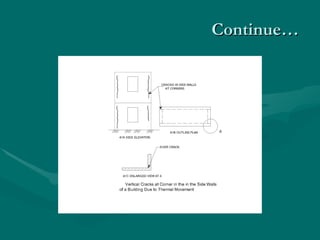

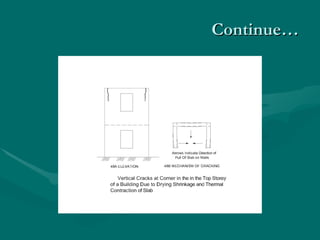

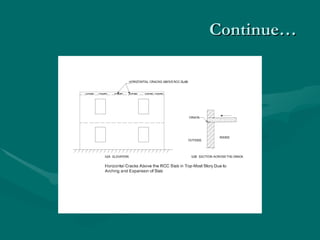

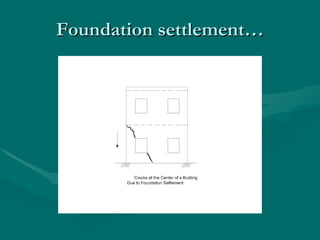

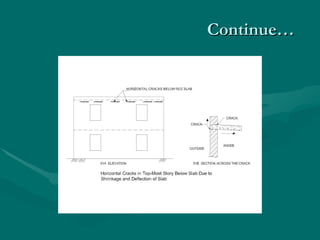

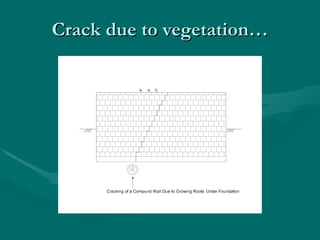

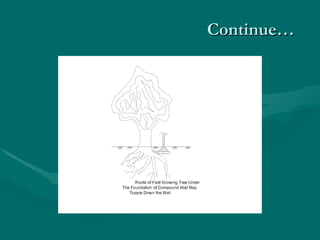

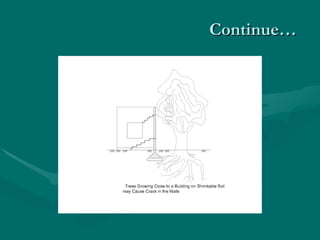

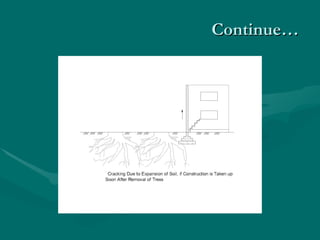

The document discusses various causes and classifications of cracks in buildings, highlighting internal stress factors, material properties, and construction practices that lead to structural and non-structural cracks. It emphasizes the importance of moisture control, proper curing, and other preventive measures to mitigate crack formation during and after the construction process. The text also addresses the significance of understanding the mechanics of concrete behavior under various environmental conditions to maintain structural integrity.