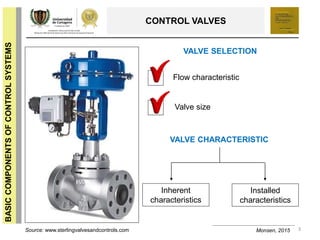

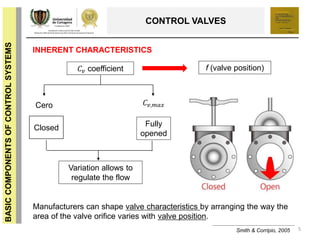

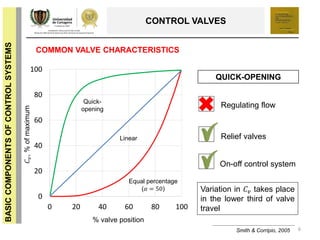

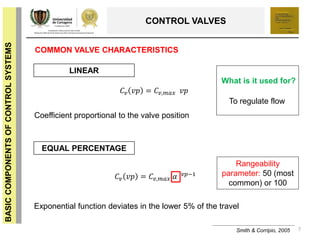

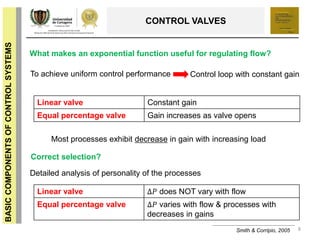

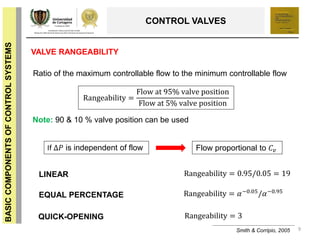

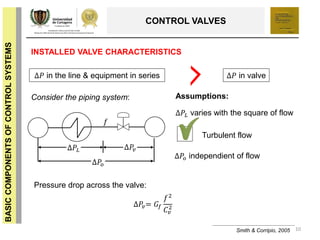

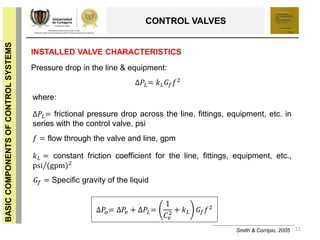

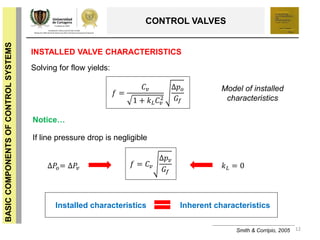

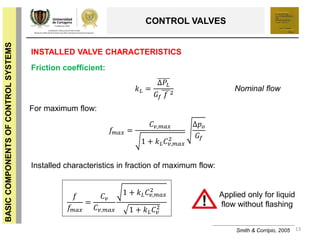

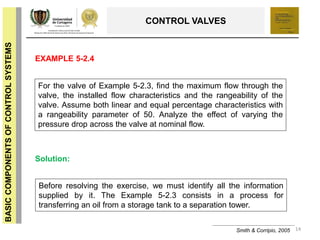

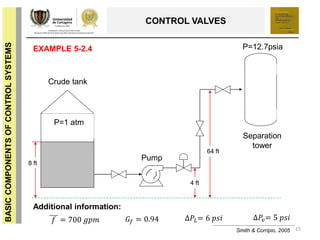

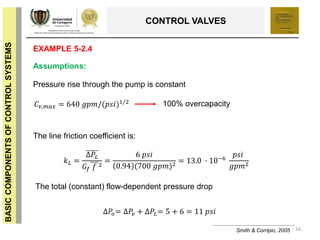

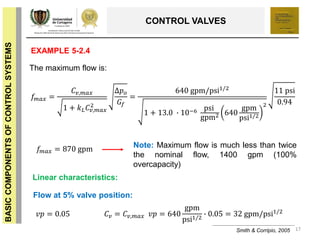

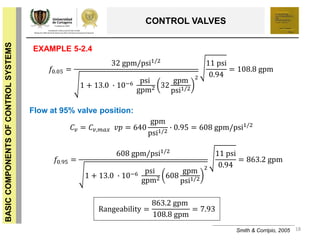

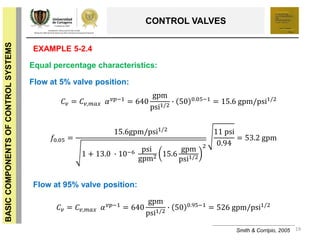

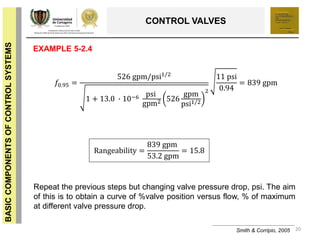

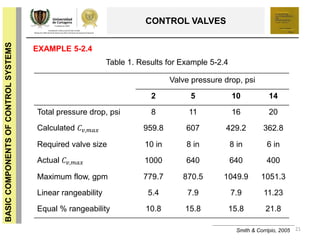

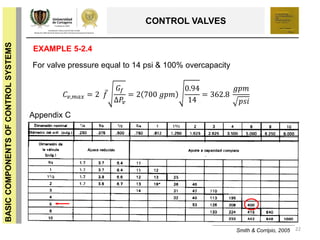

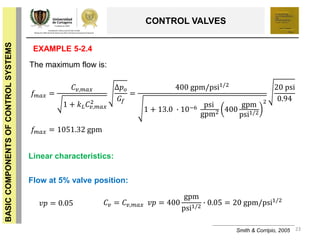

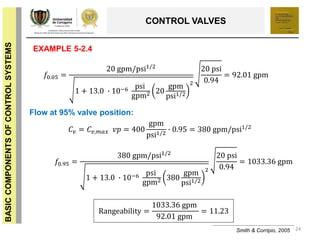

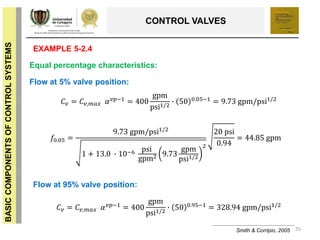

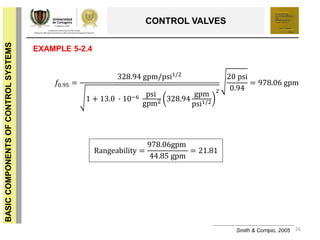

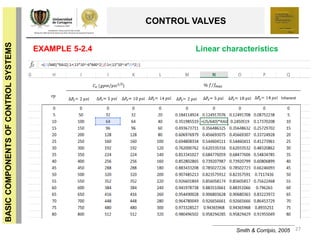

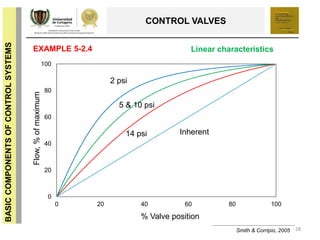

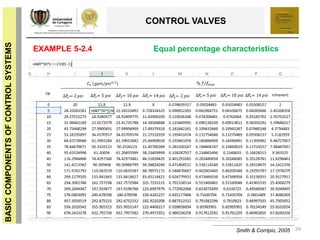

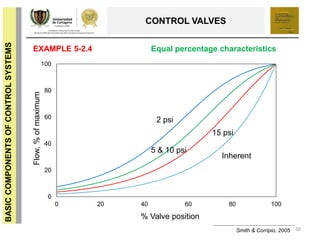

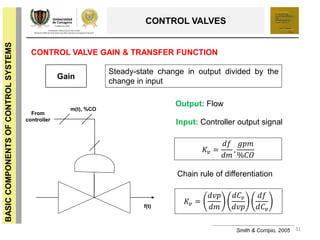

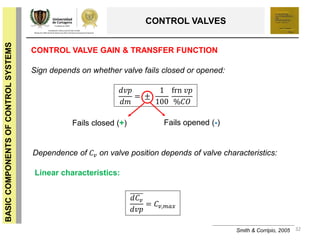

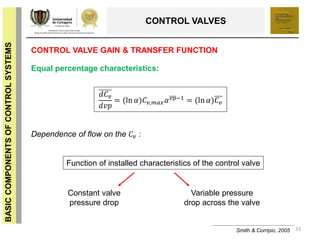

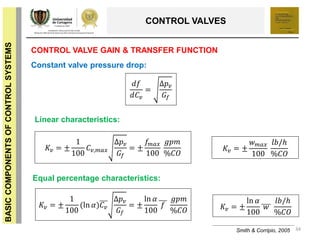

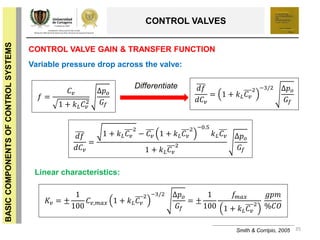

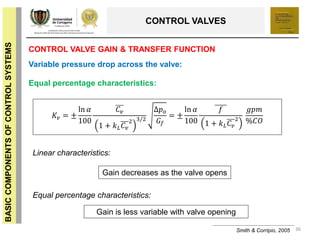

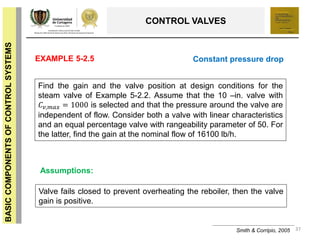

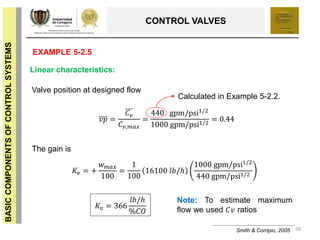

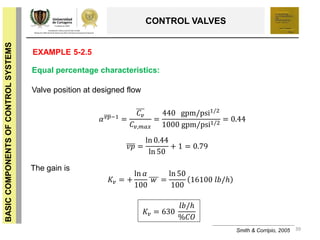

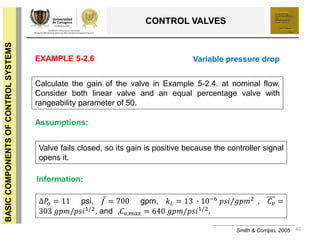

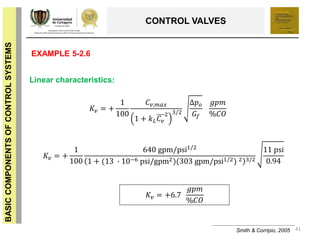

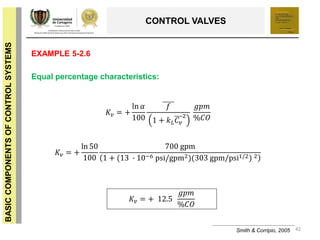

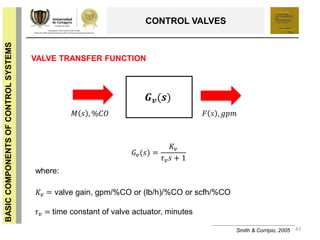

The document discusses control valves in chemical engineering, detailing their characteristics, gain, and transfer functions, emphasizing the importance of valve selection and performance analysis. It includes descriptions of inherent and installed characteristics, flow capacity, and the variation of flow control using different valve types such as linear and equal percentage. Additionally, it provides examples and calculations for understanding the operational rangeability and pressure drops across control valves.