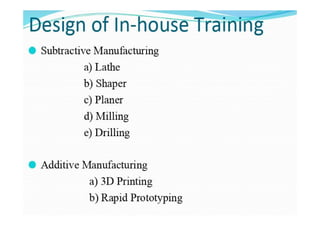

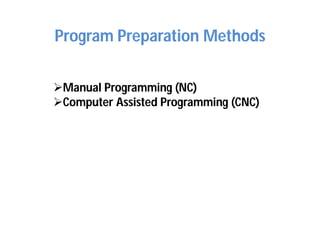

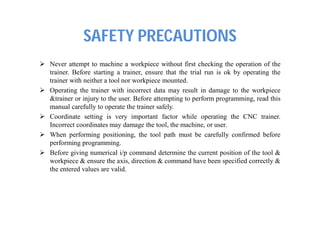

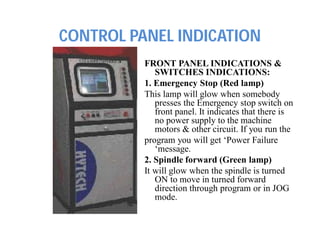

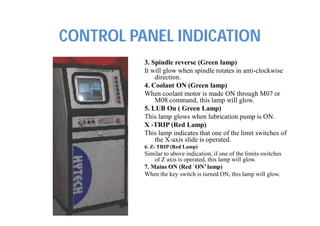

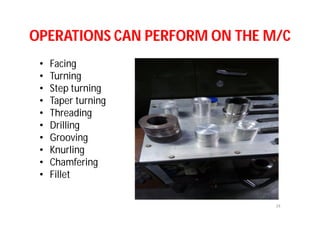

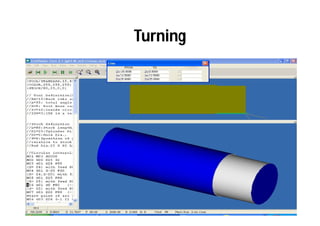

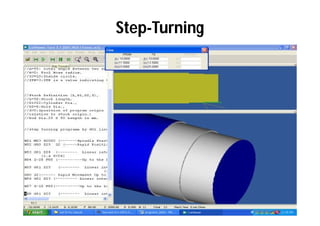

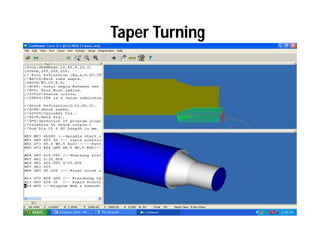

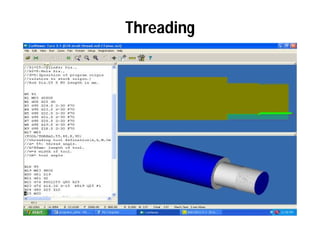

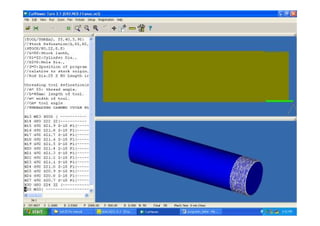

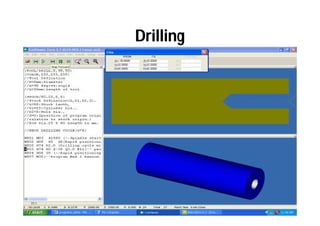

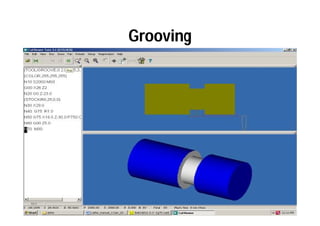

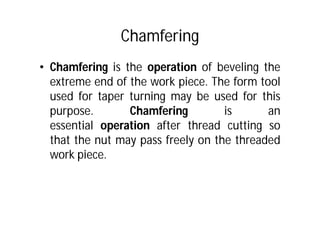

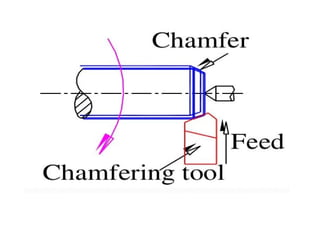

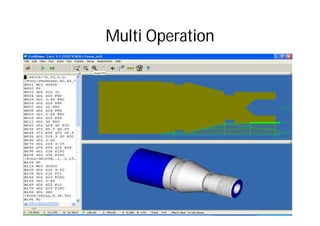

The document provides information about conducting an in-house summer training on CNC lathe machines. It discusses the aims of the training, which are to familiarize trainees with basic CNC machine operations, teach theoretical and practical CNC concepts, and help increase confidence. It also outlines safety precautions and covers various machining operations that can be performed on a CNC lathe like turning, threading, and drilling.