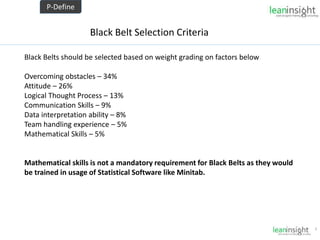

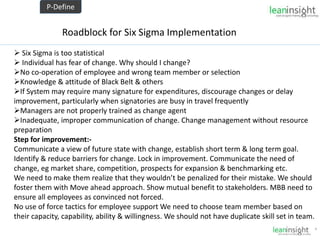

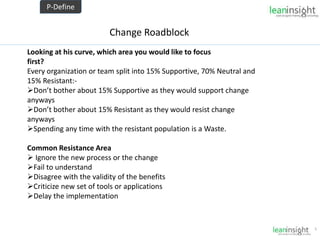

The document outlines the criteria for selecting Black Belts in Lean Six Sigma training, emphasizing the importance of attitude, communication, and team handling over mathematical skills. It discusses roadblocks to Six Sigma implementation such as fear of change and inadequate communication, highlighting the need for proper change management and employee buy-in. Additionally, it covers the concepts of continuous improvement and Kaizen, stressing the significance of incremental changes and the cyclical nature of process enhancement.