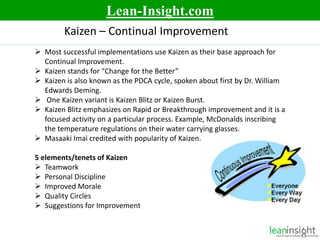

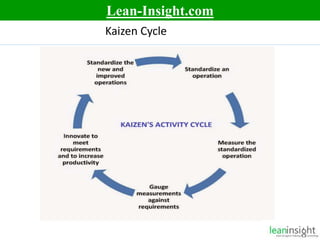

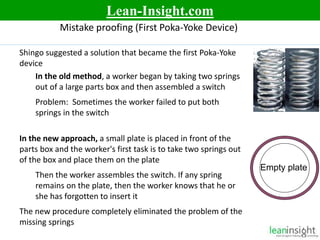

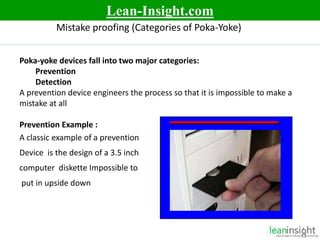

The document discusses the concept of kaizen, a Japanese term for continuous improvement which emphasizes the involvement of all employees in making incremental changes for better performance. It explains the kaizen blitz approach, a focused short-term event aimed at rapid improvements, and outlines the principles of mistake-proofing (poka-yoke) to prevent errors in processes. Additionally, it touches on statistical process control (SPC) as a method for monitoring process variations and improving overall quality management.