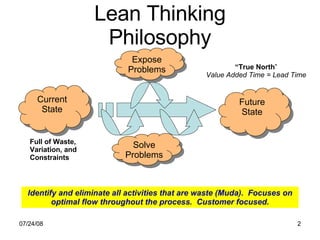

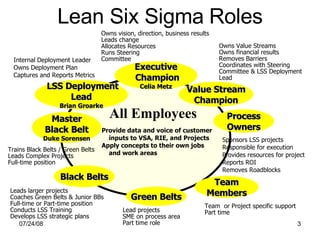

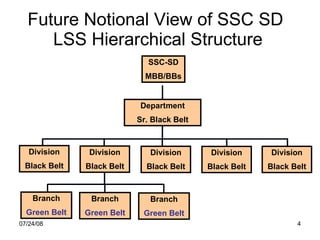

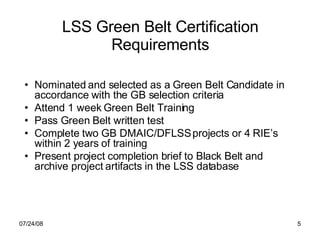

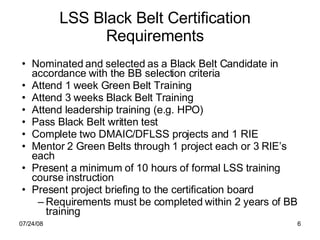

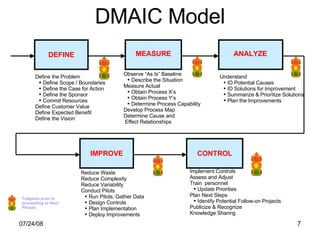

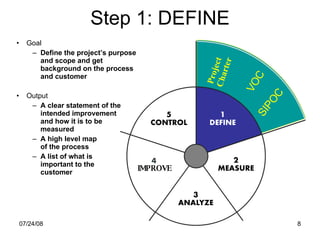

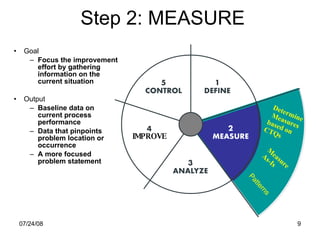

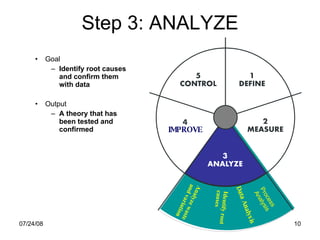

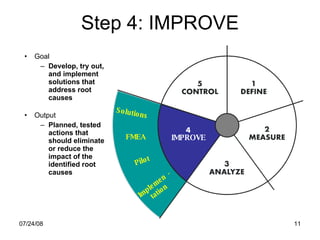

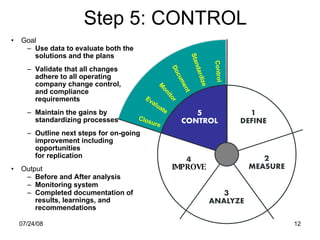

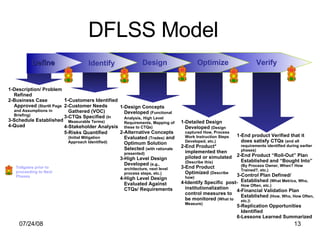

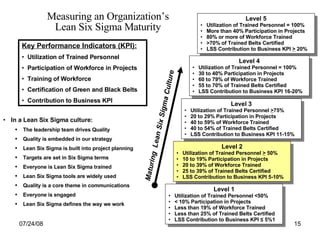

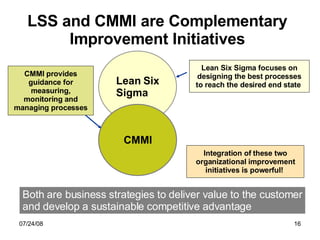

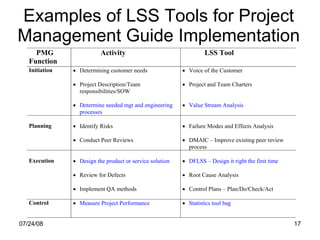

The document provides information on Lean Six Sigma, including its roles, models, and tools. It discusses the Lean Six Sigma hierarchy and certification requirements for Green Belts and Black Belts. The DMAIC model for process improvement is described along with metrics for measuring an organization's Lean Six Sigma maturity. Lean Six Sigma and CMMI are presented as complementary process improvement initiatives.