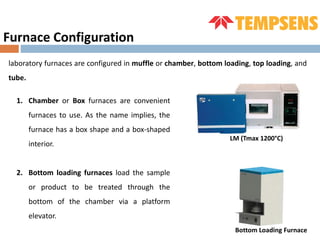

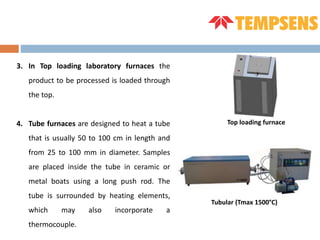

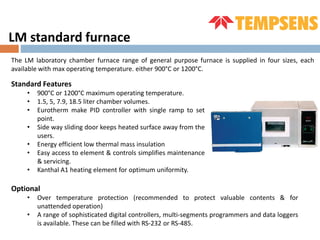

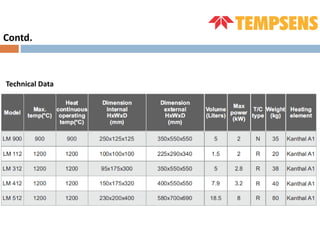

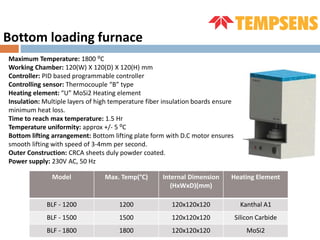

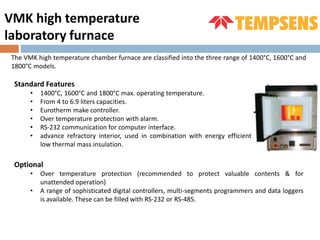

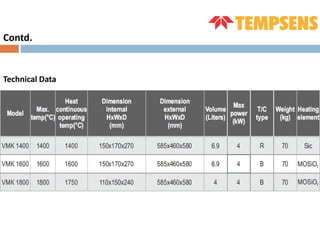

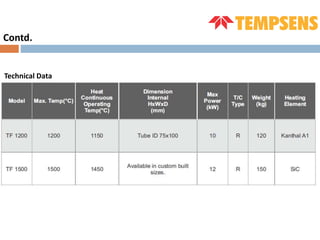

The document details various types of laboratory furnaces, including chamber, bottom loading, top loading, and tubular models, along with their specifications and applications. It emphasizes critical considerations such as maximum temperature, chamber dimensions, and heating elements for effective selection and usage in research and industrial settings. Additionally, features like over-temperature protection and programmable controllers are highlighted for enhanced performance and safety.