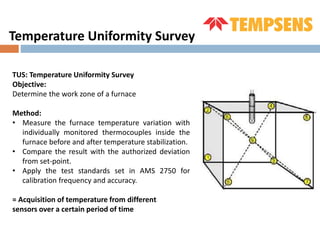

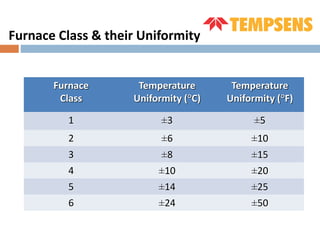

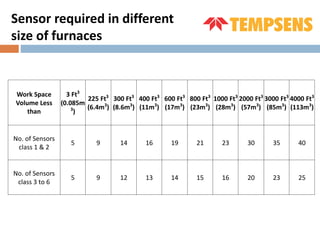

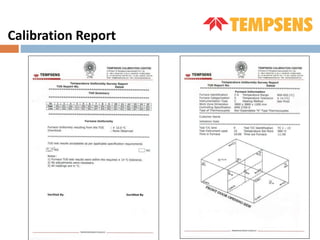

The document discusses furnace calibration requirements according to the AMS 2750E aerospace standard. It describes the need for temperature uniformity surveys (TUS) to determine a furnace's work zone and ensure uniform heating. TUS involves measuring temperature variations across a furnace using thermocouples and comparing results to the standard's allowable deviations. The document also covers furnace classes and their uniformity requirements, sensor requirements, how to conduct a TUS, and the related system accuracy test (SAT) to determine temperature control errors.