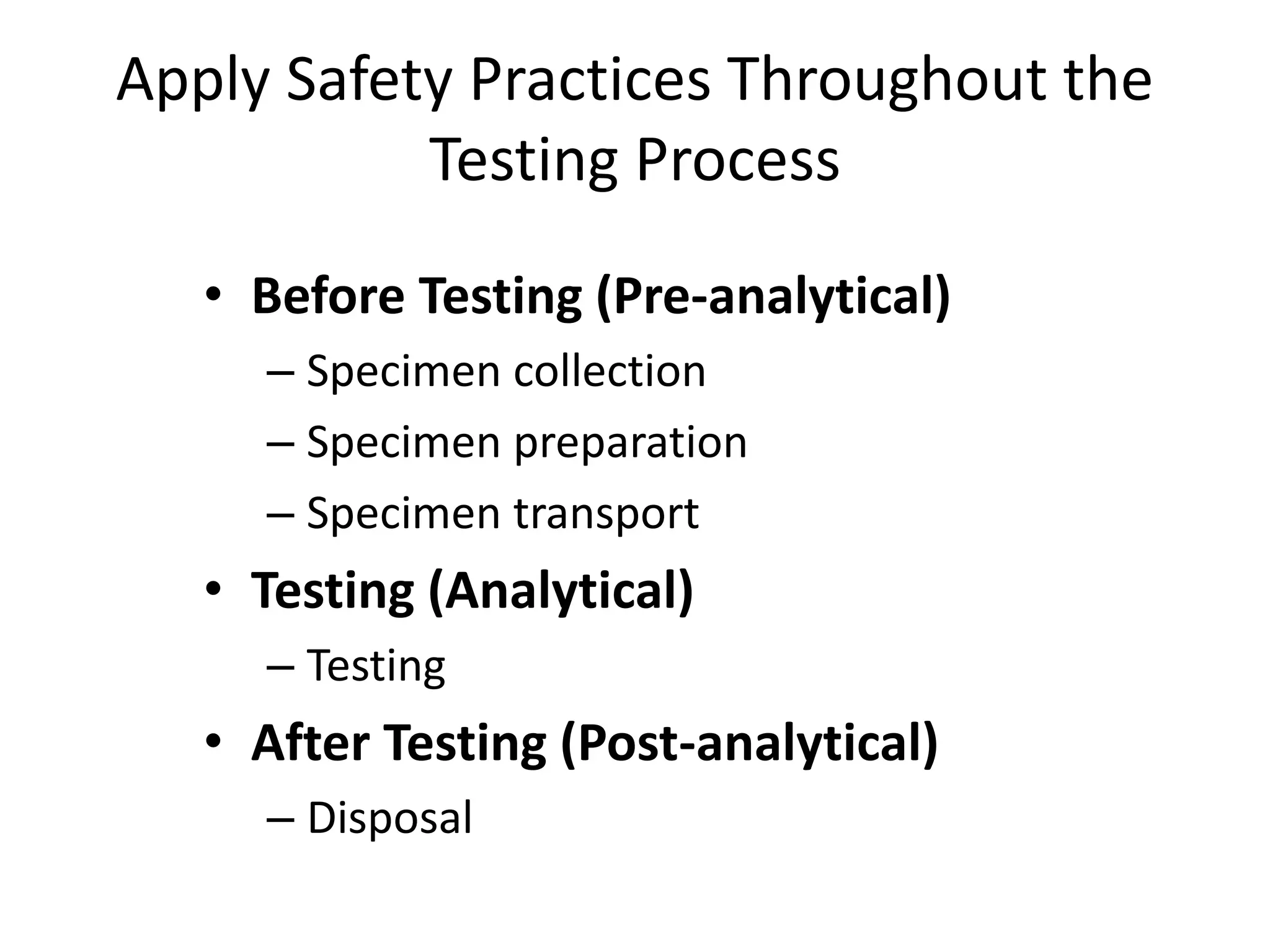

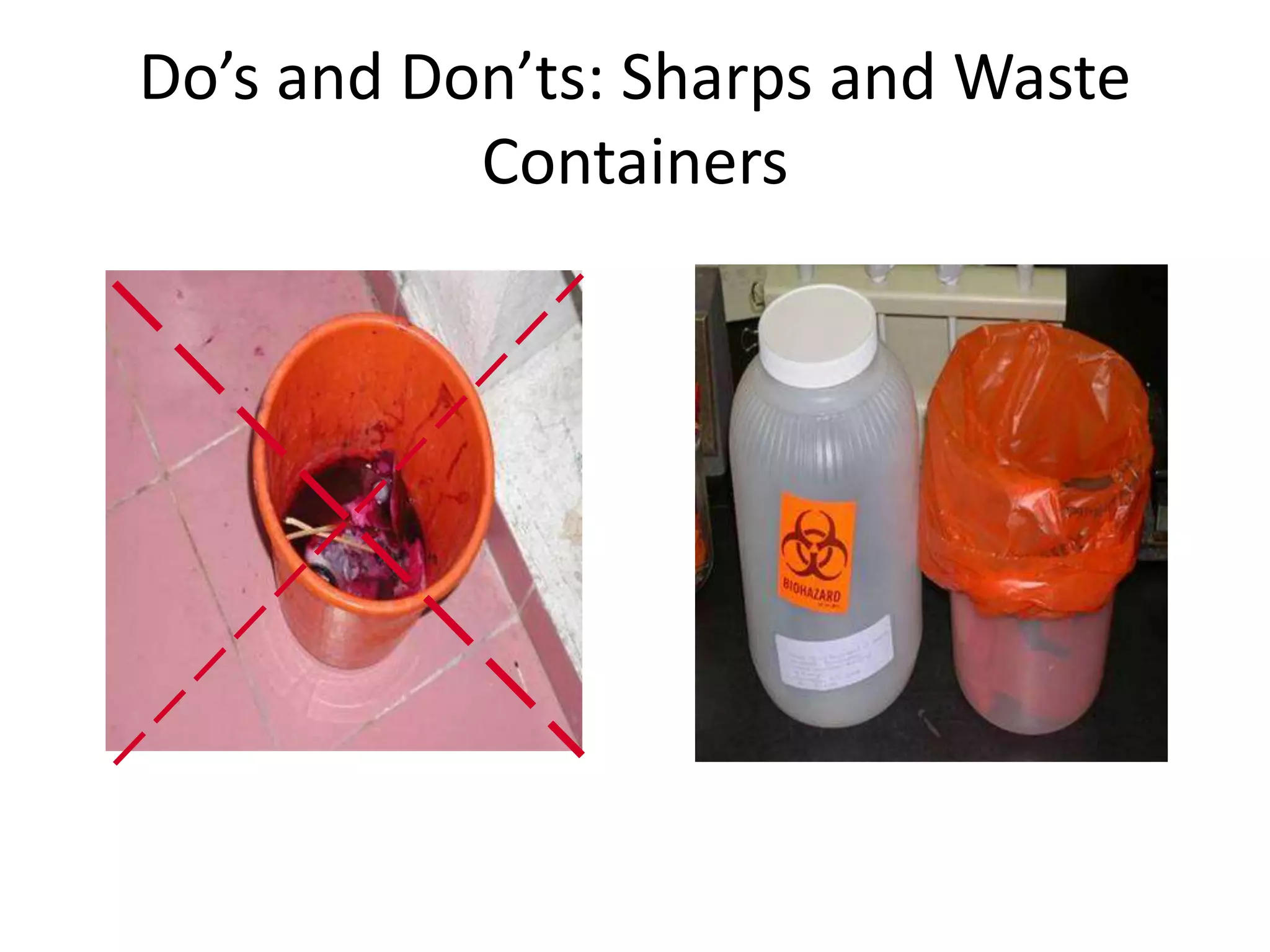

This document outlines various laboratory safety measures that should be followed. It discusses following universal precautions by treating all specimens as infectious. It describes relevant UK health and safety laws and the importance of performing risk assessments. It also provides guidance on proper use of personal protective equipment, developing safe work habits, maintaining a clean work space, safe sharps handling and waste disposal, disinfection procedures, classification of microorganisms, and responding to accidents. General laboratory hazards are identified and safe practices for equipment, materials, and electrical safety are outlined.