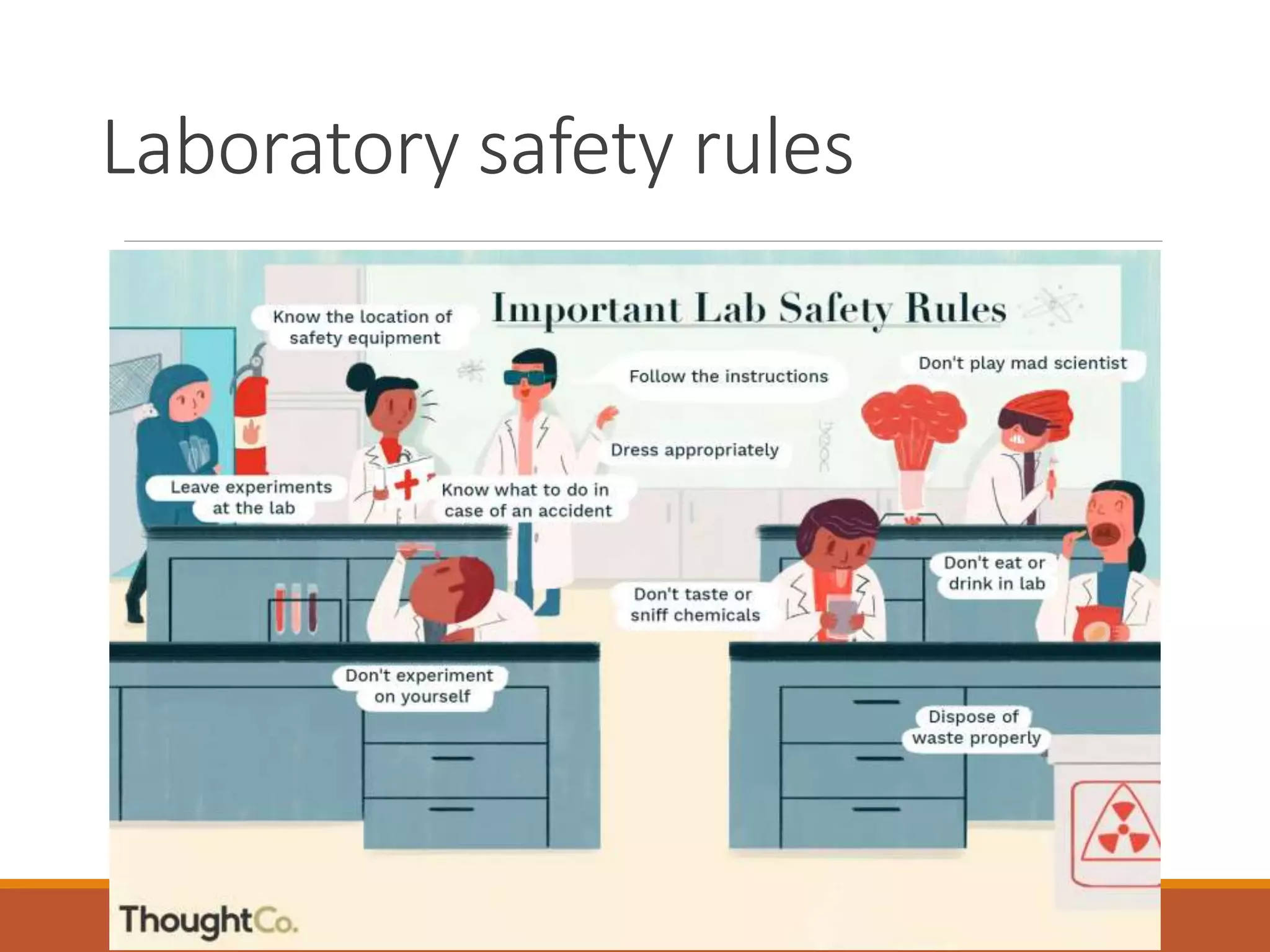

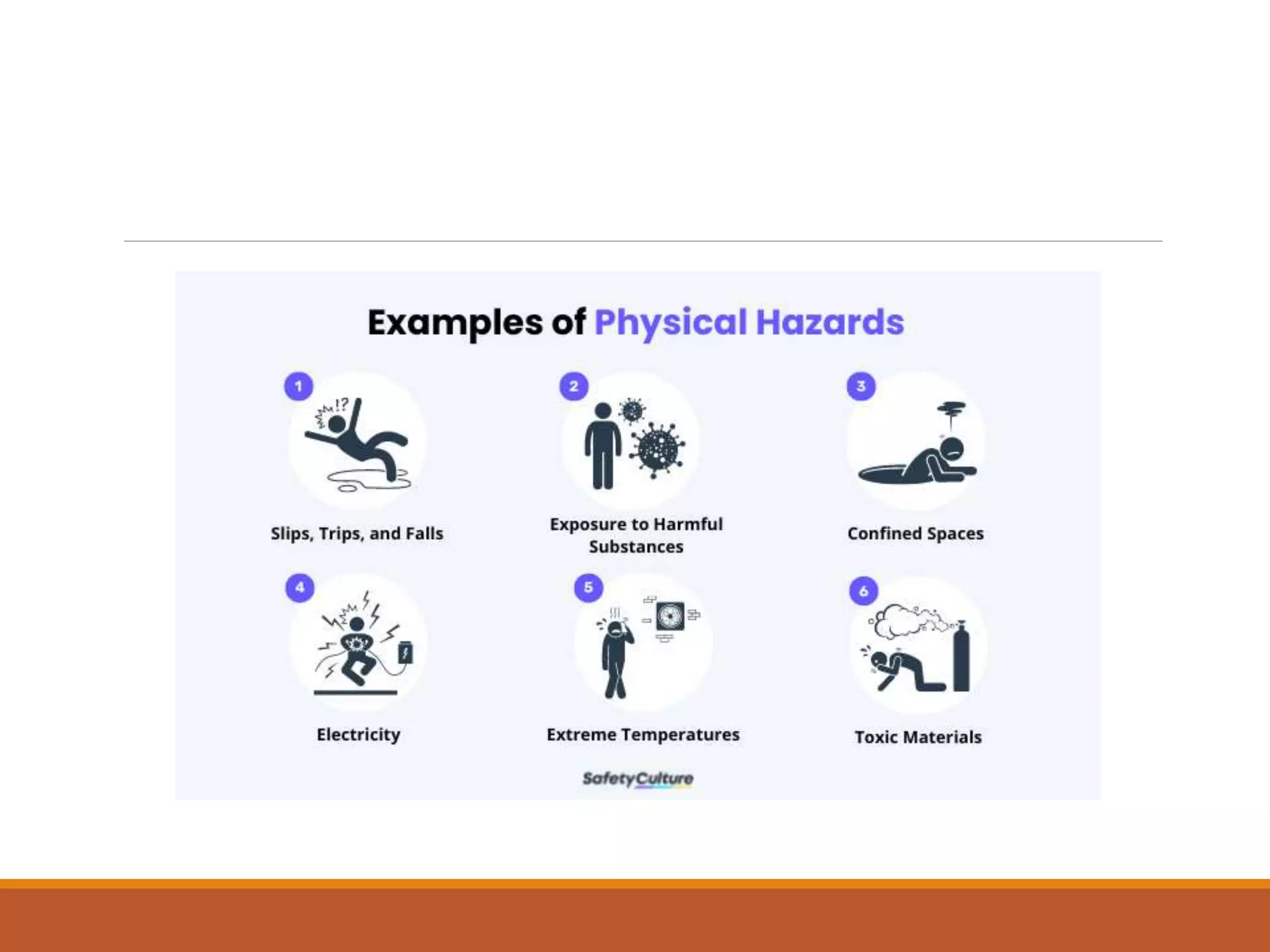

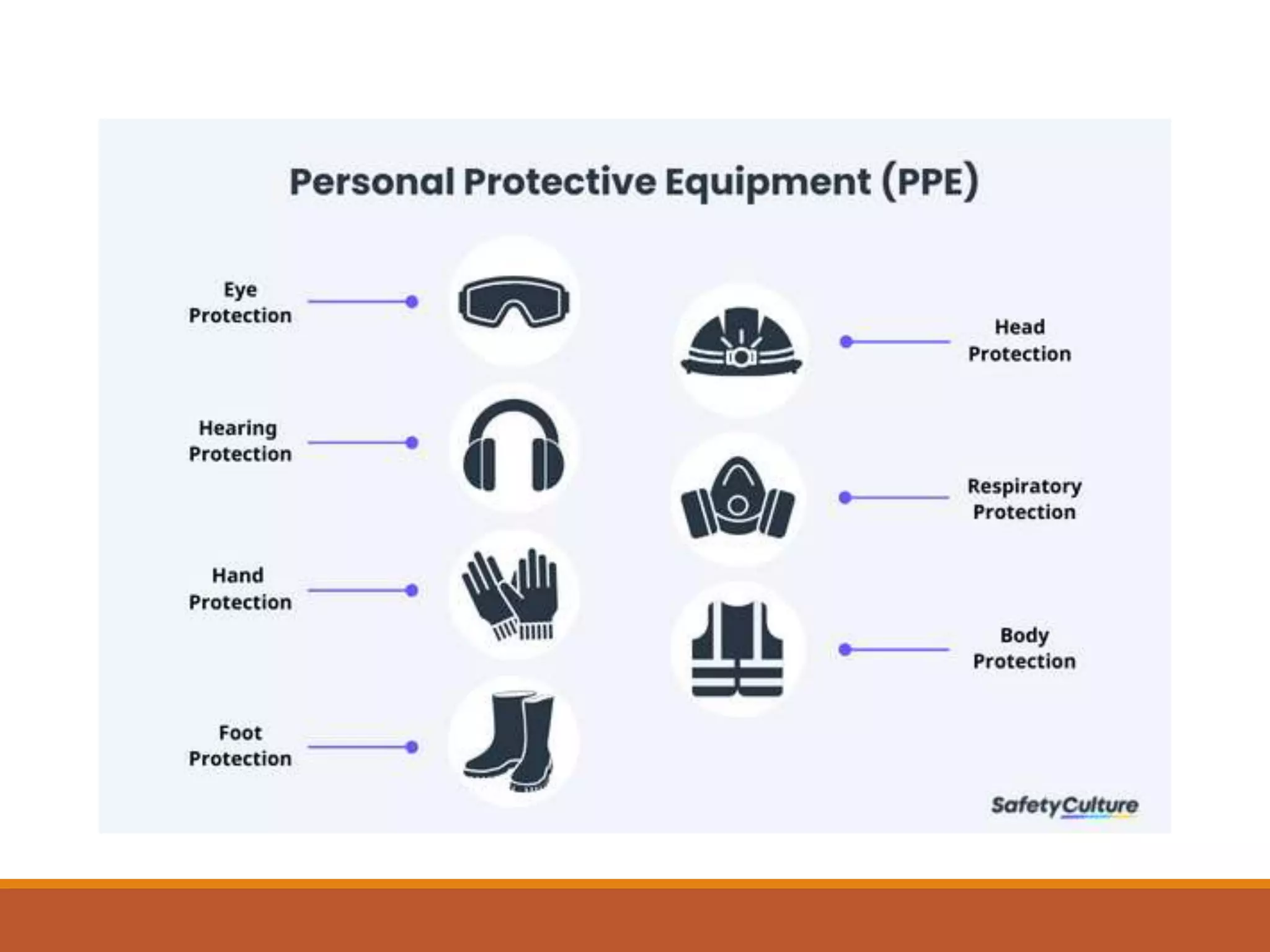

This document provides guidance on laboratory safety policies and procedures. It outlines the roles and responsibilities of management, laboratory supervisors, and individual employees to ensure a safe work environment. General safety rules are established, such as following evacuation plans, using protective equipment properly, and disposing of waste correctly. Hazards in the laboratory including chemical, biological, physical, and electrical dangers are discussed. The importance of safety data sheets, labeling, signage, and personal protective equipment to minimize risks is also explained.