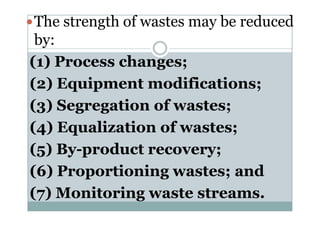

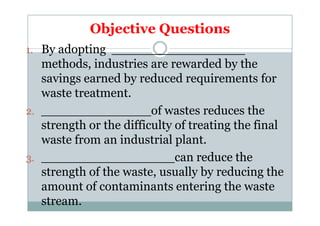

1. Waste strength reduction is the second major objective for industrial plants concerned with waste treatment. Methods to reduce the total amount of polluting matter in wastes include process changes, equipment modifications, segregation of wastes, equalization of wastes, by-product recovery, proportioning wastes, and monitoring waste streams.

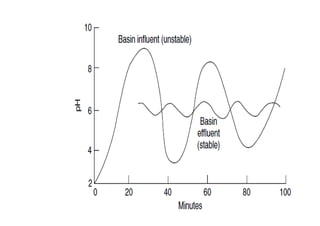

2. Segregation of wastes reduces the strength or difficulty of treating the final waste by creating two wastes - a small, strong waste and a larger, weaker waste that can be treated with methods specific to each. Equalization of wastes stabilizes characteristics like pH and BOD by holding wastes for a period of time.

3. By-product recovery from wastes