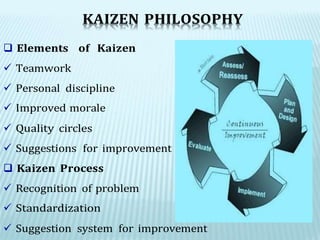

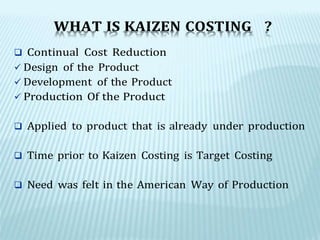

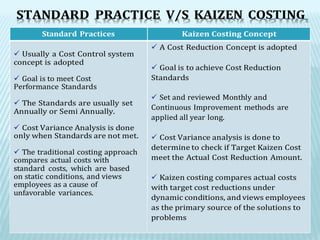

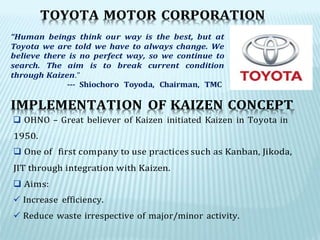

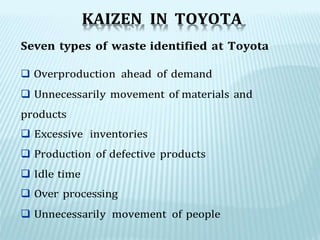

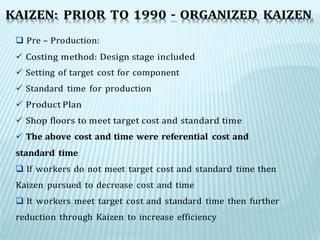

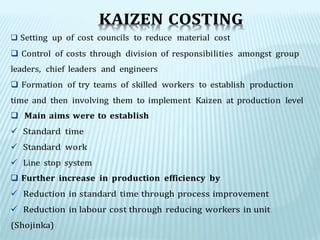

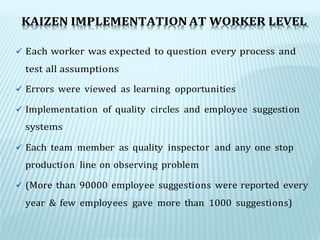

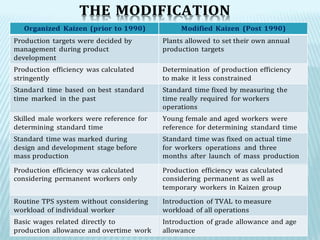

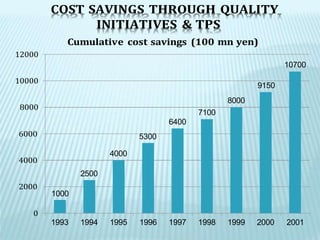

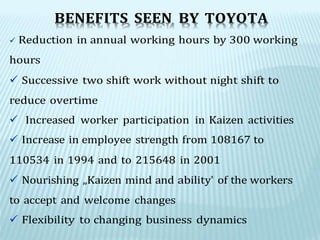

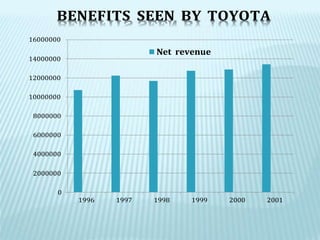

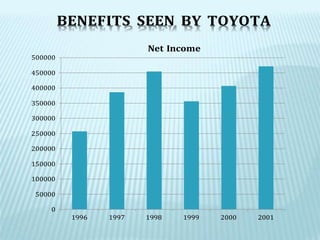

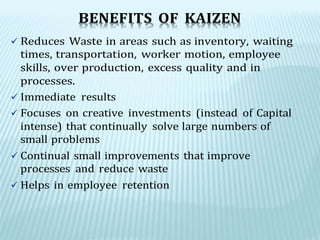

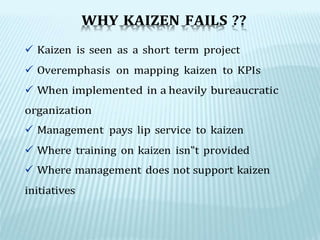

Kaizen is a Japanese philosophy of continuous improvement involving all employees. It was first implemented successfully at Toyota to continuously reduce costs and improve processes. The key aspects of Kaizen include teamwork, problem identification, standardization, and suggestion systems. Toyota modified its implementation of Kaizen in the 1990s to be more human-centered in response to labor shortages. This resulted in significant annual cost savings and increased revenues and profits for Toyota over time. Kaizen fails when not fully supported by management and seen as only a short-term initiative rather than a long-term continuous improvement strategy.