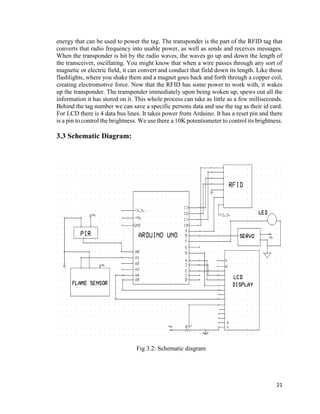

This document discusses automating an office environment using various sensors. It describes using RFID cards to automatically identify and greet employees upon entry. Motion detectors and a flame sensor are used for energy saving, automatic control of electronics, and fire safety. The objectives are to create a secure, safe working environment with automatic door control, lighting/device control based on presence detection, and fire alerts. Required hardware includes an Arduino, RFID components, sensors, and display. Software includes the Arduino IDE. Detailed descriptions of the Arduino, servo motor, and flame sensor components are also provided.

![3

CHAPTER 2

DETAILS OF THE COMPONENTS

2.1Arduino:

Arduino/Genuino Uno is a microcontroller board based on the ATmega328P. It has 14

digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16

MHz quartz crystal, a USB connection, a power jack, an ICSP header and a reset button. It

contains everything needed to support the microcontroller; simply connect it to a computer

with a USB cable or power it with an AC-to-DC adapter or battery to get started. You can

tinker with your UNO without worrying too much about doing something wrong, worst

case scenario you can replace the chip for a few dollars and start over again. "Uno" means

one in Italian and was chosen to mark the release of Arduino Software (IDE) 1.0. The Uno

board and version 1.0 of Arduino Software (IDE) were the reference versions of Arduino,

now evolved to newer releases. The Uno board is the first in a series of USB Arduino

boards, and the reference model for the Arduino platform; for an extensive list of current,

past or outdated boards see the Arduino index of boards. [1]

Fig 2.1: Arduino](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-3-320.jpg)

![4

2.1.1 Arduino specification:

Microcontroller ATmega328P

Operating Voltage 5v

Input voltage 7-12v

Input voltage limit 6-20v

Digital I/O Pins 6

Analogue input Pins 6

DC current perI/O pins 20 mA

DC current for 3.3v Pin 50 mA

Flash Memory Of which o.5KB is used

SRAM 2 KB

EEPROM 1KB

Clock Speed 16MHz

Length 68.6mm

Width 53.4nm

Weight 25g

Table 2.1

2.1.2 Arduino programming:

The Arduino/Genuino Uno can be programmed with the (Arduino Software (IDE)).Select

"Arduino/Genuino Uno from the Tools > Board menu (according to the microcontroller on

your board). The ATmega328 on the Arduino/Genuino Uno comes preprogrammed with a

boot loader that allows us to upload new code to it without the use of an external hardware

programmer. It communicates using the original STK500 protocol (reference, C header

files).

We can also bypass the boot loader and program the microcontroller through the ICSP (In-

Circuit Serial Programming) header using Arduino ISP or similar. The ATmega16U2/8U2

is loaded with a DFU boot loader, which can be activated by:

On Rev1 boards: connecting the solder jumper on the back of the board (near the

map of Italy) and then rese ing the 8U2.

On Rev2 or later boards: there is a resistor that pulling the 8U2/16U2 HWB line to

ground, making it easier to put into DFU mode. [1]

2.1.3 Warnings:

The Arduino/Genuino Uno has a resettable polyfuse that protects your computer's USB

ports from shorts and overcurrent. Although most computers provide their own internal](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-4-320.jpg)

![5

protection, the fuse provides an extra layer of protection. If more than 500 mA is applied

to the USB port, the fuse will automatically break the connection until the short or

overload is removed. [1]

2.1.4 Differences with other boards:

The Uno differs from all preceding boards in that it does not use the FTDI USB-to-serial

driver chip. Instead, it features the Atmega16U2 (Atmega8U2 up to version R2)

programmed as a USB-to-serial converter. [1]

2.1.5 Power:

The Arduino/Genuino Uno board can be powered via the USB connection or with an

external power supply. The power source is selected automatically.

External (non-USB) power can come either from an AC-to-DC adapter (wall-wart) or

battery. The adapter can be connected by plugging a 2.1mm center-positive plug into the

board's power jack. Leads from a battery can be inserted in the GND and VIN pin headers

of the POWER connector.

The board can operate on an external supply from 6 to 20 volts. If supplied with less than

7V, however, the 5V pin may supply less than five volts and the board may become

unstable. If using more than 12V, the voltage regulator may overheat and damage the

board. The recommended range is 7 to 12 volts.

The power pins are as follows:

VIN. The input voltage to the Arduino/Genuino board when it's using an external

power source (as opposed to 5 volts from the USB connection or other regulated

power source). One can supply voltage through this pin, or, if supplying voltage via

the power jack, access it through this pin.

5V.This pin outputs a regulated 5V from the regulator on the board. The board can

be supplied with power either from the DC power jack (7 - 12V), the USB connector

(5V), or the VIN pin of the board (7-12V). Supplying voltage via the 5V or 3.3V

pins bypasses the regulator, and can damage your board. We don't advise it.

3V3. A 3.3 volt supply generated by the on-board regulator. Maximum current draw

is 50 mA.

GND. Ground pins.

IOREF. This pin on the Arduino/Genuino board provides the voltage reference with

which the microcontroller operates. A properly configured shield can read the

IOREF pin voltage and select the appropriate power source or enable voltage

translators on the outputs to work with the 5V or 3.3V. [1]

2.1.6 Memory:

The ATmega328 has 32 KB (with 0.5 KB occupied by the boot loader). It also has 2 KB

of SRAM and 1 KB of EEPROM (which can be read and written with the EEPROM

library). [1]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-5-320.jpg)

![6

2.1.7 Input & Output:

Each of the 14 digital pins on the Uno can be used as an input or output, using pin mode

(), digital write (), and digital read () functions. They operate at 5 volts. Each pin can

provide or receive 20 mA as recommended operating condition and has an internal pull-

up resistor (disconnected by default) of 20-50k ohm. A maximum of 40mA is the value

that must not be exceeded on any I/O pin to avoid permanent damage to the

microcontroller.

In addition, some pins have specialized functions:

Serial: 0 (RX) and 1 (TX). Used to receive (RX) and transmit (TX) TTL serial

data. These pins are connected to the corresponding pins of the ATmega8U2

USB-to-TTL Serial chip.

External Interrupts: 2 and 3. These pins can be configured to trigger an interrupt

on a low value, a rising or falling edge, or a change in value. See the attach

interrupt () function for details.

PWM: 3, 5, 6, 9, 10, and 11. Provide 8-bit PWM output with the analog write ()

function.

SPI: 10 (SS), 11 (MOSI), 12 (MISO), 13 (SCK). These pins support SPI

communication using the SPI library.

LED: 13. There is a built-in LED driven by digital pin 13. When the pin is HIGH

value, the LED is on, when the pin is LOW, it's off.

TWI: A4 or SDA pin and A5 or SCL pin. Support TWI communication using the

Wire library.

The Uno has 6 analog inputs, labeled A0 through A5, each of which provide 10 bits of

resolution (i.e. 1024 different values). By default they measure from ground to 5 volts,

though is it possible to change the upper end of their range using the AREF pin and the

analog reference () function.

There are a couple of other pins on the board:

AREF. Reference voltage for the analog inputs. Used with analog Reference ().

Reset. Bring this line LOW to reset the microcontroller. Typically used to add a

reset button to shields which block the one on the board. [1]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-6-320.jpg)

![7

Fig 2.2: Pin Specification

2.1.8 Communication:

Arduino/Genuino Uno has a number of facilities for communicating with a computer,

another Arduino/Genuino board, or other microcontrollers. The ATmega328 provides

UART TTL (5V) serial communication, which is available on digital pins 0 (RX) and 1

(TX). An ATmega16U2 on the board channels this serial communication over USB and

appears as a virtual com port to software on the computer. The 16U2 firmware uses the

standard USB COM drivers, and no external driver is needed. However, on Windows, an

.inf file is required. The Arduino Software (IDE) includes a serial monitor which allows

simple textual data to be sent to and from the board. The RX and TX LEDs on the board

will flash when data is being transmitted via the USB-to-serial chip and USB connection

to the computer (but not for serial communication on pins 0 and 1).

A Software serial library allows serial communication on any of the Uno's digital pins.

The ATmega328 also supports I2C (TWI) and SPI communication. The Arduino Software

(IDE) includes a Wire library to simplify use of the I2C bus; see the documentation for

details. For SPI communication, use the SPI library. [1]

2.1.9Automatic (Software) Reset:

Rather than requiring a physical press of the reset button before an upload, the

Arduino/Genuino Uno board is designed in a way that allows it to be reset by software

running on a connected computer. One of the hardware flow control lines (DTR) of the](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-7-320.jpg)

![8

ATmega8U2/16U2 is connected to the reset line of the ATmega328 via a 100 nano farad

capacitor. When this line is asserted (taken low), the reset line drops long enough to reset

the chip. The Arduino Software (IDE) uses this capability to allow you to upload code by

simply pressing the upload button in the interface toolbar. This means that the boot loader

can have a shorter timeout, as the lowering of DTR can be well-coordinated with the start

of the upload. This setup has other implications. When the Uno is connected to either a

computer running Mac OS X or Linux, it resets each time a connection is made to it from

software (via USB). For the following half-second or so, the boot loader is running on the

Uno. While it is programmed to ignore malformed data (i.e. anything besides an upload of

new code), it will intercept the first few bytes of data sent to the board after a connection

is opened. If a sketch running on the board receives one-time configuration or other data

when it first starts, make sure that the software with which it communicates waits a second

after opening the connection and before sending this data.

The Uno board contains a trace that can be cut to disable the auto-reset. The pads on either

side of the trace can be soldered together to re-enable it. It's labeled "RESET-EN". You

may also be able to disable the auto-reset by connecting a 110 ohm resistor from 5V to the

reset line.[ 1 ]

2.2 Servo Motor:

Servo motors have been around for a long time and are utilized in many applications. They

are small in size but pack a big punch and are very energy-efficient. These features allow

them to be used to operate remote-controlled or radio-controlled toy cars, robots and

airplanes. Servo motors are also used in industrial applications, robotics, in-line

manufacturing, pharmaceutics and food services. The servo circuitry is built right inside

the motor unit and has a positional shaft, which usually is fitted with a gear (as shown

below). The motor is controlled with an electric signal which determines the amount of

movement of the shaft.

To fully understand how the servo works, you need to take a look under the hood. Inside

there is a pretty simple set-up: a small DC motor, potentiometer, and a control circuit. The

motor is attached by gears to the control wheel. As the motor rotates, the potentiometer's

resistance changes, so the control circuit can precisely regulate how much movement there

is and in which direction. When the shaft of the motor is at the desired position, power

supplied to the motor is stopped. If not, the motor is turned in the appropriate direction.

The desired position is sent via electrical pulses through the signal wire. The motor's speed

is proportional to the difference between its actual position and desired position. So if the

motor is near the desired position, it will turn slowly, otherwise it will turn fast. This is

called proportional control. This means the motor will only run as hard as necessary to

accomplish the task at hand, a very efficient little guy. [2]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-8-320.jpg)

![9

Fig 2.3: Servo motor

2.2.1 Controlling of servo:

Servos are controlled by sending an electrical pulse of variable width, or pulse width

modulation (PWM), through the control wire. There is a minimum pulse, a maximum

pulse, and a repetition rate. A servo motor can usually only turn 90 degrees in either

direction for a total of 180 degree movement. The motor's neutral position is defined as the

position where the servo has the same amount of potential rotation in the both the clockwise

or counter-clockwise direction. The PWM sent to the motor determines position of the

shaft, and based on the duration of the pulse sent via the control wire; the rotor will turn to

the desired position. The servo motor expects to see a pulse every 20 milliseconds (ms)

and the length of the pulse will determine how far the motor turns. For example, a 1.5ms

pulse will make the motor turn to the 90-degree position. Shorter than 1.5ms moves it to 0

degrees, and any longer than 1.5ms will turn the servo to 180 degrees.

When these servos are commanded to move, they will move to the position and hold that

position. If an external force pushes against the servo while the servo is holding a position,

the servo will resist from moving out of that position. The maximum amount of force the

servo can exert is called the torque rating of the servo. Servos will not hold their position

forever though; the position pulse must be repeated to instruct the servo to stay in position.

[ 2 ]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-9-320.jpg)

![10

Fig 2.4: Parts of a Servo

2.3 Flame sensor:

The Grove - Flame Sensor can be used to detect fire source or other light sources of the

wavelength in the range of 760nm - 1100 nm. It is based on the YG1006 sensor which is a

high speed and high sensitive NPN silicon phototransistor. Due to its black epoxy, the

sensor is sensitive to infrared radiation. In firefighting robot game, the sensor plays a very

important role, it can be used as a robot eyes to find the fire source.[3]

Fig 2.5: Flame sensor

2.3.1 Feature:

Grove Interface

High Photo Sensitivity

Fast Response Time

Easy to use

Sensitivity can adjustable](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-10-320.jpg)

![11

2.3.2 Specification:

Item Min Typical Max Unit

Voltage 4.75 5.0 5.30 VDC

Current / 20 / mA

Range of Spectral

Bandwidth

760 940 1100 nm

Detection range 0 ~ 1 m

Response Time 15 μS

Operating Temperature -25 ~ 85 ℃

Table 2.2

2.3.3 Usage:

The module is mainly used to detect the infrared light. It outputs digital signal 0 and 1

through a Comparator output. The output value will be 0 when infrared light is detected.

And the sensitivity is adjustable by the precision potentiometer.

Let's use it to control. When the output value is 0, the led will light up.

1. Connect the module to the D3 of Grove - Base Shield using the 4-pin grove cable.

2. Plug the Grove - Base Shield into Arduino.

3. Connect Arduino to PC by using a USB cable.

4. Copy and paste code below to a new Arduino sketch. Please click here if you do

not know how to upload.

5. The LED will light up when there is infrared light. Please use it to design your

products. [3]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-11-320.jpg)

![12

2.3.4 Graphical view:

Sensor can detect the light source whose wavelength is in the range of 760nm - 1100 nm.

The below picture shows the spectral sensitivity. [3]

Fig 2.6: Range of sensitivity of flame sensor.

2.4 RFID:

As a self-confessed tin-hatter and someone who has worked with asset management and

inventory controls, I’ve got a lot of interest in RFID technology. I’ll get to that in a few

paragraphs. First off, one need to know what RFID is an initialization of – Radio Frequency

Identification Tag. The initialization is pronounced ARE-FID. Well, they are a way of

assigning unique data to whatever they are applied to. Like a barcode or an ISBN number

in some ways. The problem with things like bar codes is that they can get damaged or even

switched. Some people to try to get expensive things cheaper – highly illegal. An RFID tag

can be as small as a grain of black pepper and be embedded right into a product’s

packaging, or the product itself. So you can start to see some of the benefits here.](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-12-320.jpg)

![13

Most RFID’s do not have an internal power source, like a battery, but some do. I’m going

to cover the ones that don’t, as they are the ones that are most popular. The RFID

technology has two components – the reader and the tag. The reader has two parts – a

transceiver and an antenna. The transceiver generates a weak radio signal that may have a

range from a few feet to a few yards. The signal is necessary to wake or activate the tag

and is transmitted through the antenna. The signal itself is a form of energy that can be

used to power the tag.

The transponder is the part of the RFID tag that converts that radio frequency into usable

power, as well as sends and receives messages. When the transponder is hit by the radio

waves, the waves go up and down the length of the transceiver, oscillating. You might

know that when a wire passes through any sort of magnetic or electric field, it can convert

and conduct that field down its length. Like those flashlights, where you shake them and a

magnet goes back and forth through a copper coil, creating electromotive force.

Now that the RFID has some power to work with, it wakes up the transponder. The

transponder immediately upon being woken up, spews out all the information it has stored

on it. This whole process can take as little as a few milliseconds. Imagine having friend

who was hypnotized to wake up upon hearing a code word, tell you his name and phone

number, and then fall immediately back to sleep. Yet he wouldn’t do this no matter what

else you said. Funny, yes it is. That’s pretty much what RFID technology does.[4]

2.4.1 Mifare MFRC522 RFID Reader/Writer:

There are cheap RFID modules that can read and write Mifare's tags and being sold at

several web stores, like eBay and included with many "starter kits" nowadays. Simply

search RFID-RC522 (MF-RC522). The microcontroller and card reader uses SPI for

communication (chip supports I2C and UART protocols but not implemented on library)

(Maybe someone implements?). The card reader and the tags communicate using a

13.56MHz electromagnetic field. (ISO 14443A standard tags). [5]

2.4.2 General description on RFID:

The MFRC522 is a highly integrated reader/writer IC for contactless communication at

13.56 MHz the MFRC522 reader supports ISO/IEC 14443 A/MIFARE and NTAG. The

MFRC522’s internal transmitter is able to drive a reader/writer antenna designed to

communicate with ISO/IEC 14443 A/MIFARE cards and transponders without additional

active circuitry. The receiver module provides a robust and efficient implementation for

Demodulating and decoding signals from ISO/IEC 14443 A/MIFARE compatible cards

and transponders. The digital module manages the complete ISO/IEC 14443 a framing and

error detection (parity and CRC) functionality. The MFRC522 supports MF1xxS20,](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-13-320.jpg)

![14

MF1xxS70 and MF1xxS50 products. The MFRC522 supports contactless communication

and uses MIFARE higher transfer speeds up to 848 kBd in both directions. [6]

Fig 2.7: RFID-RC522

2.4.3 Features & Benefits:

1. Highly integrated analog circuitry to demodulate and decode responses

2. Buffered output drivers for connecting an antenna with the minimum

number of external components

3. Supports ISO/IEC 14443 A/MIFARE and NTAG

4. Typical operating distance in Read/Write mode up to 50 mm depending on

the antenna size and tuning

5. Supports MF1xxS20, MF1xxS70 and MF1xxS50 encryption in Read/Write

mode

6. Supports ISO/IEC 14443 A higher transfer speed communication up to 848

kBdSupports MFIN/MFOUT

7. Additional internal power supply to the smart card IC connected via

MFIN/MFOUT

8. Supported host interfaces

9. SPI up to 10 Mbit/s

10. C-bus interface up to 400 kBd in Fast mode, up to 3400 kBd in High-speed

mode

11. RS232 Serial UART up to 1228.8 kBd, with voltage levels dependent on

pin voltage supply

12. FIFO buffer handles 64 byte send and receive Flexible interrupt modes Hard

reset with low power function & power-down by software mode

Programmable timer

13. Internal oscillator for connection to 27.12 MHz quartz crystal

14. 2.5 V to 3.3 V power supply

15. CRC coprocessor

16. Programmable I/O pins and internal self-test [6]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-14-320.jpg)

![15

2.5 PIR motion sensor:

Passive Infra-Red (PIR) sensor is an electronic device commonly used in security lighting,

and burglar alarm systems. A PIR sensor is a motion detector which detects the heat

(infrared) emitted naturally by humans and animals. When a person in the field of vision

of the sensor moves, the sensor detects a sudden change in infrared energy and the sensor

is triggered (activated).Passive Infrared Detectors At the front of a PIR sensor unit is a

fresnel lens (pictured above). This special kind of lens is used to gather light from a very

wide field of view and focus it directly onto a passive infrared sensor (as shown

below).Some electronics inside the PIR sensor unit then decide whether the infrared light

detected is from a warm moving body, and if so, triggers a switch. [7]

2.5.1 Uses:

A commonest use for a PIR sensor is automatic security lighting. Whenever a suitably

large (and therefore probably human) warm body moves in the field of view of the sensor,

a floodlight is switched on automatically and left on for a fixed period of time - typically

30-90 seconds *. This can be used to deter burglars as well as providing lighting when you

arrive home at night. The duration the light is left on for can usually be set by the user.

Such PIR security lighting systems are available. [7]

2.5.2 Weaknesses of PIR sensors:

In order for a PIR sensor to work well most of the time, they are designed with certain

limitations. A PIR sensor cannot detect a stationary or very slowly moving body - if the

sensor was set to the required sensitivity, it would be activated by the cooling of a nearby

wall in the evening, or by very small animals. Similarly, if someone walks straight towards

a PIR sensor, it will not detect them until they are very close by. PIR sensors are

temperature sensitive - they work optimally at ambient air temperatures of around 15-20

degrees Celsius. If the temperature is over 30 degrees, the field of view narrows and the

sensor will be less sensitive. Alternatively, if the temperature is below 15 degrees, the field

of view widens and smaller or more distant objects will activate the sensor. [7]

2.5.3 Working Process:

Here, we are using a PIR motion sensor. PIR stands for Passive Infrared. This motion

sensor consists of a fresnel lens, an infrared detector and supporting detection circuitry.

The lens on the sensor focuses any infrared radiation/wavelengths present around it

towards the infrared detector. Our bodies generate infrared heat and as a result this gets

picked up by the motion sensor. The sensor outputs a 5V signal for a period of one minute

as soon as it detects us. It offers a tentative range of detection of about 6-7 m and is highly

sensitive. The output from the sensor (5V) is used to trigger a transistor BC547. The

transistor then switches on a 5V relay. The relay correspondingly switches your appliance

ON. [7]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-15-320.jpg)

![16

Fig 2.8: PIR motion sensor

2.6 LCD:

Here is brief data for the Systronix 20x4 character LCD. We're not aware of any

incompatibilities between the two - at least we have never seen any in all the code and

custom applications we have done. This 20x4 LCD is electrically and mechanically

interchangeable with 20x4 LCDs from several other vendors. The only differences we've

seen among different 20x4 LCDs are:

1) LED backlight brightness, voltage and current vary widely, as does the quality of the

display

2) There is a resistor “Rf” which sets the speed of the LCD interface by controlling the

internal oscillator frequency. Several displays we have evaluated have a low resistor value.

This makes the display too slow. Looking at the Hitachi data sheet page 56, it appears that

perhaps the “incorrect” resistor is really intended for 3V use of the displays. At 5V the

resistor Rf should be 91 K ohms. At 3V it should be 75 K ohms. Using a 3V display at 5V

is acceptable from a voltage standpoint (the display can operate on 3-5V) but the oscillator

will then be running too slowly. One fix is to always check the busy flag and not use a

fixed time delay in your code, then it will work regardless of the LCD speed. The other

option is to always allow enough delay for the slower display. All systronix 20x4 LCDs

have the 91 K ohm resistor and are intended for 5V operation. [8]](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-16-320.jpg)

![18

Contrast Ratio(Type) No

Colors No

Viewing Direction 6:00

Viewing Angle Range No

Brightness(Type) No

Backlight Color White Color

Backlight Current

(Type)

75mA

Power Supply(Type) 3.3V, 5V

Supply Current for

LCM(Max)

2000uA

Operating Temperature -20℃~70℃

Storage Temperature -30℃~80℃

Series Number ERM2004-2 [8]

Fig 2.9: LCD Display.](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-18-320.jpg)

![19

2.7 Potentiometer:

An adjustable potentiometer can open up many interesting user interfaces. Turn the pot and

the resistance changes. Connect VCC to an outer pin, GND to the other, and the center pin

will have a voltage that varies from 0 to VCC depending on the rotation of the pot. Hook

the center pin to an ADC on a microcontroller and get a variable input from the user. This

pot has a ¼" mounting diameter and has a 10K linear taper. Check the datasheet for

dimensional drawings. [9]

This potentiometer is a two-in-one, good in a breadboard or with a panel. It’s a fairly

standard linear taper 10K ohm potentiometer, with a grippy shaft. It’s smooth and easy to

turn, but not so loose that it will shift on its own. We like this one because the legs are 0.2"

apart with pin-points, so you can plug it into a breadboard or perfboard. Once you're done

prototyping, you can drill a hole into your project box and mount the potentiometer that

way. [10]

Fig 2.10: Potentiometer](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-19-320.jpg)

![27

APPENDIX:

Program o Arduino:

//-----------------------RFID--------------------//

#include <SPI.h>

#include <RFID.h>

#include <Servo.h>

#define SS_PIN 10

#define RST_PIN 9

Servo myservo;

int pos = 0;

RFID rfid(SS_PIN,RST_PIN);

int serNum[5];

int cards[][5] = {

{132,1,219,233,183},

{110,41,232,213,122}

};

int x;

int i;

bool access = false;

bool a = false;

bool b = false;

//-------------------------rfid--------------------------//](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-27-320.jpg)

![30

myservo.write(pos);

if(rfid.isCard()){

if(rfid.readCardSerial())

{

Serial.print(rfid.serNum[0]);

Serial.print(" ");

Serial.print(rfid.serNum[1]);

Serial.print(" ");

Serial.print(rfid.serNum[2]);

Serial.print(" ");

Serial.print(rfid.serNum[3]);

Serial.print(" ");

Serial.print(rfid.serNum[4]);

Serial.println("");

for( x = 0; x < sizeof(cards); x++)

{

for( i = 0; i < sizeof(rfid.serNum); i++ )

{

if(rfid.serNum[i] != cards[x][i])

{

access = false;](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-30-320.jpg)

![31

break;

}

else access=true;

if(cards[x][i] != cards[0][i])

{

a = false;

}

else a=true;

if(cards[x][i] != cards[1][i])

{

b = false;

}

else b=true;

}

if (access) break;

}

} if (a) {lcd.setCursor(0,0);

lcd.print("Roll:124006");

delay(1000);}

if (b) {lcd.setCursor(0,0);

lcd.print("Ashfaqul Haque Roll:124006");

delay(1000);}](https://image.slidesharecdn.com/59fb445b-edb3-4d3b-bca2-4ed96021fcd2-161101201549/85/Office-automation-system-using-arduino-31-320.jpg)