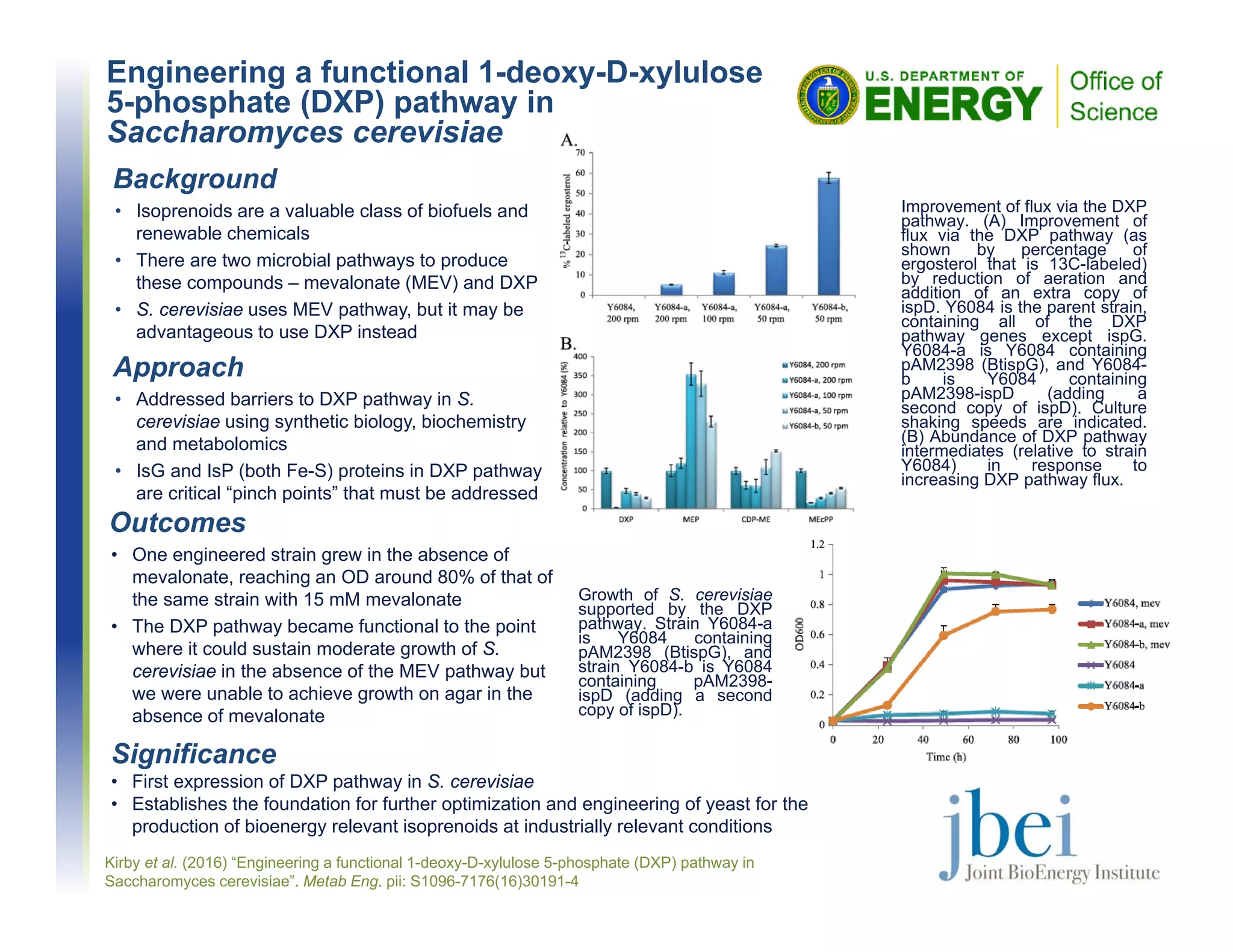

The document describes research that engineered the 1-deoxy-D-xylulose 5-phosphate (DXP) pathway in the yeast Saccharomyces cerevisiae. Key findings include:

- An engineered strain was able to grow in the absence of mevalonate, reaching 80% of growth compared to strains with mevalonate added.

- The DXP pathway became functional enough to support moderate growth without the mevalonate pathway, but growth on agar without mevalonate was not achieved.

- This work established a foundation for further optimizing yeast to produce bioenergy-relevant isoprenoids through the DXP pathway under industrial conditions.

![Genome-resolved metagenomics defines a

community response to ionic liquid challenge

Outcomes

• Increasing levels of ionic liquid amendment in the cultures selects for a Firmicutes-dominated communities that retain the

ability to produce glycoside hydrolases up to 2% [C2C1im][OAc]. At 2% [C2C1im][OAc], the community switches to acetate

metabolism

• The combination of genome-resolved metagenomics (>100 genomes were recovered from the metagenomic dataset) and

metatranscriptomics allowed the identification of individual community members that were tolerant of [C2C1im][OAc] and

were able to produce cellulases and xylanases in the presence of [C2C1im][OAc]

Significance

• This study provides insights into a community-level reponse to ionic liquid challenge and demonstrates the use of

genome-resolved metagenomics to identify active microbes that can tolerate industrially relevant amounts of ionic liquids

used in the deconstruction of lignocellulose.

Wu et al. (2017) "Ionic Liquids Impact the Bioenergy Feedstock-Degrading Microbiome and Transcription of

Enzymes Relevant to Polysaccharide Hydrolysis". mSystems, 1(6). doi, 10.1128/mSystems.00120-16

Background

• Previous work at JBEI has defined the response

of bacterial isolates to ionic liquids

• Cultivation of biomass-deconstructing microbial

consortia in response to ionic liquid challenge

would illuminate community responses to these

promising pretreatment chemicals

Approach

• A consortia of microbes was adapted to grow on

switchgrass under solid state cultivation and this

adapted community inoculated into switchgrass

cultures amended with increasing levels of

[C2C1im][OAc]. The response of the community to

this challenge was measured by respiration,

enzymatic assays and metatranscriptomics.](https://image.slidesharecdn.com/jbeidecember2016highlights-170119171747/85/JBEI-Research-Highlights-December-2016-4-320.jpg)

![Development of an integrated approach for

α-pinene recovery and sugar production

from loblolly pine using ionic liquids

Outcomes

• [C2C1Im][OAc] is very efficient at extracting

terpenes (i.e., α-pinene) from loblolly pine while

generating a carbohydrate-enriched stream suitable

for bioconversion into renewable biofuels and

chemicals

• Techno-economic analysis (TEA) revealed that the

α-pinene recovery after IL pretreatment could

reduce the minimum ethanol selling price (MESP)

by $0.6-1.0/gal

Papa et al. (2016) “Development of an integrated approach for α-pinene recovery and sugar

production from loblolly pine using ionic liquids", Green Chemistry, DOI: 10.1039/C6GC02637K”.

Background

• Terpenes are produced in high concentrations from

loblolly pine (Pinus taeda L.) that could represent a

valuable supplement to bioenergy production chains

Approach

• We investigated imidazolium-based ionic liquid (IL)

[C2C1Im][OAc] pretreatment in conjunction with

different analytical protocols using GC–MS, to extract

α-pinene and simultaneously pretreat the pine to

generate high yields of fermentable sugars after

saccharification

Terpene recovery (left) and glucose release (right) of different tissues of loblolly pine

Significance

• This integrated terpene extraction/lignocellulose pretreatment approach may provide a

compelling model for a biorefinery, reducing costs and increasing commercial viability

• ILs can be used to selectively extract volatile compounds from plants during pretreatment](https://image.slidesharecdn.com/jbeidecember2016highlights-170119171747/85/JBEI-Research-Highlights-December-2016-6-320.jpg)