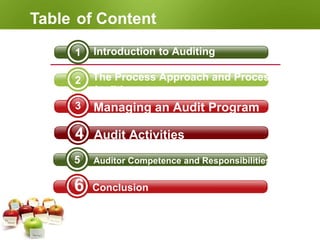

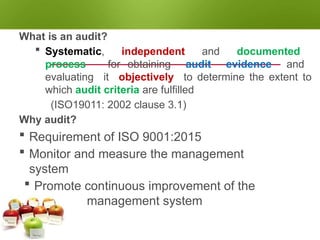

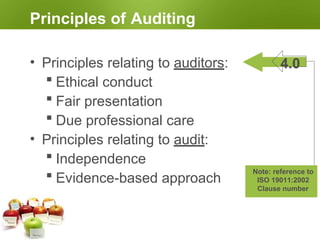

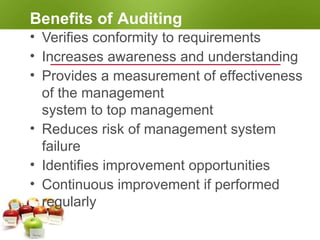

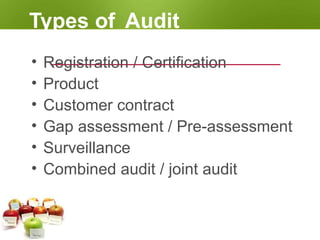

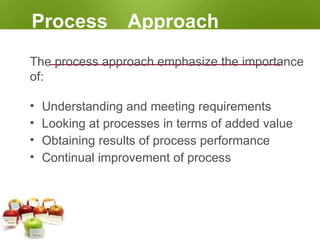

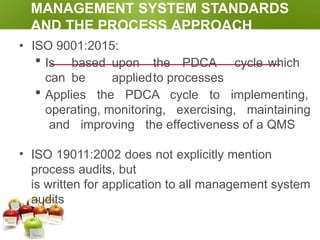

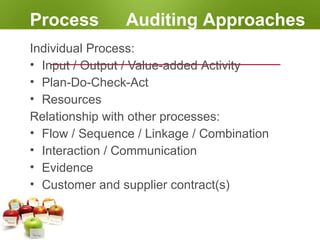

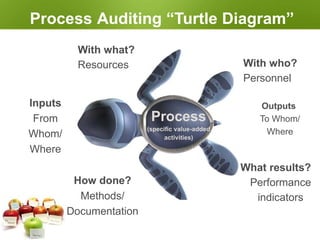

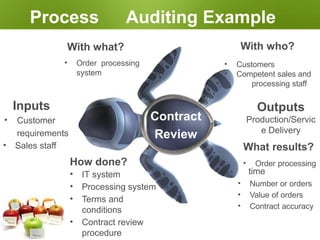

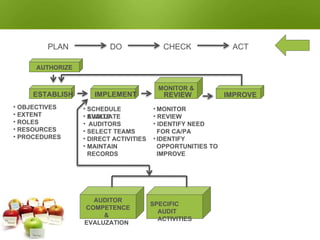

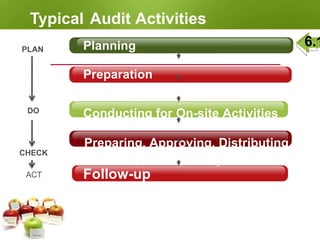

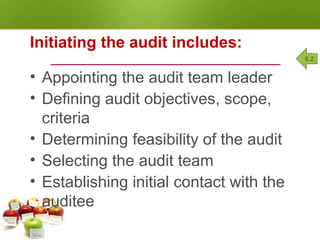

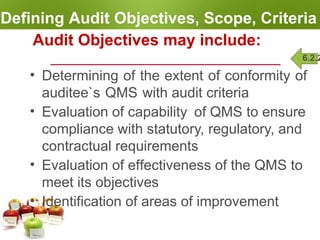

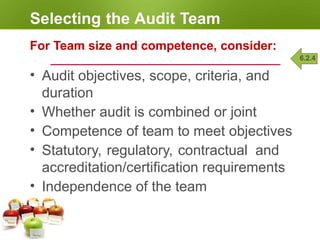

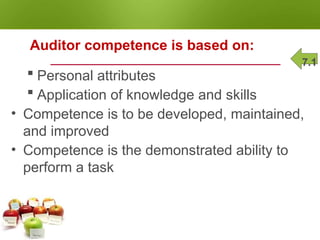

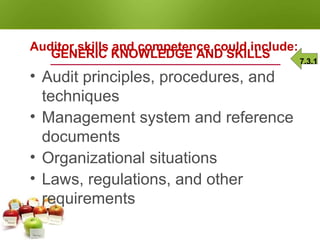

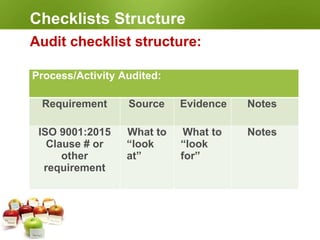

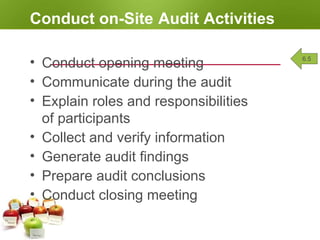

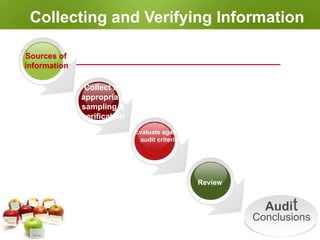

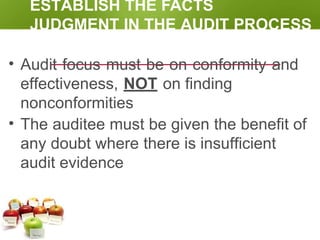

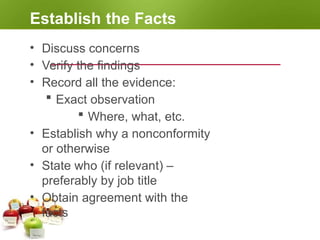

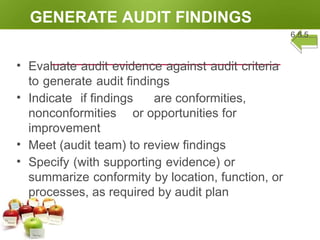

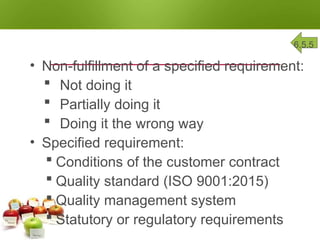

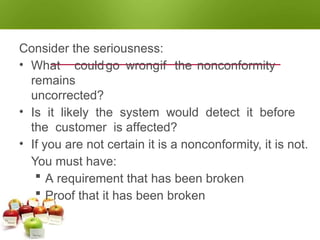

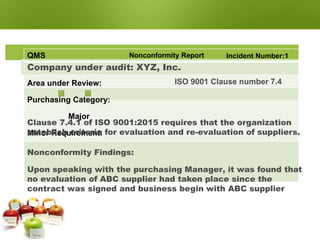

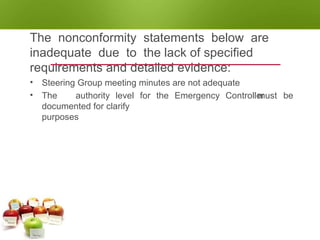

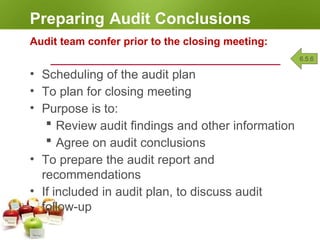

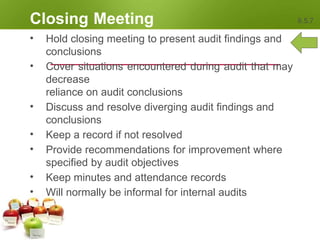

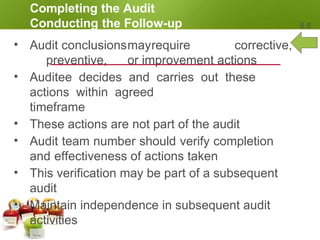

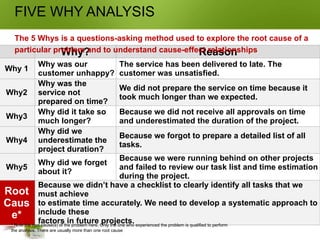

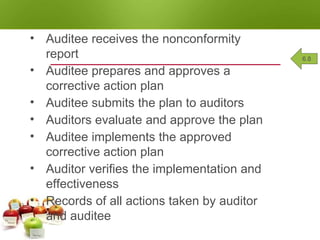

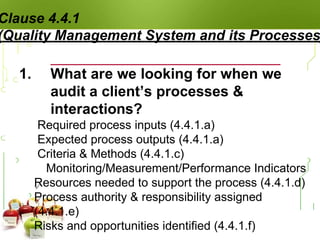

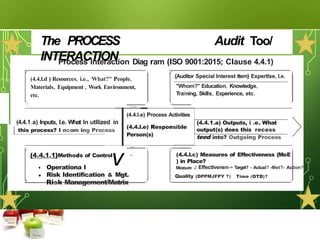

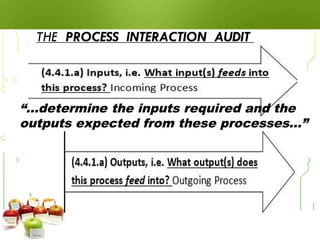

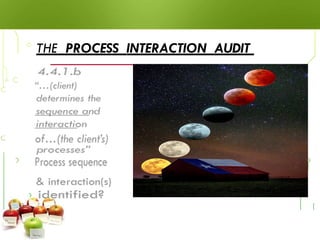

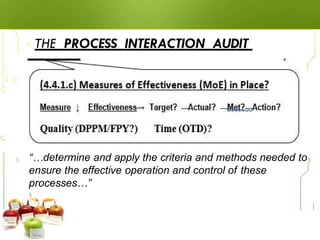

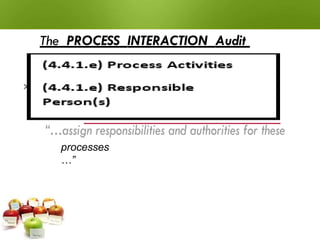

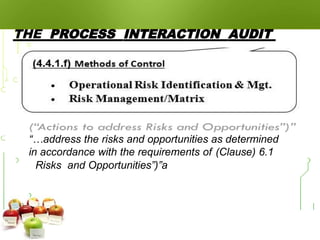

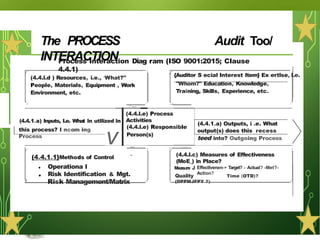

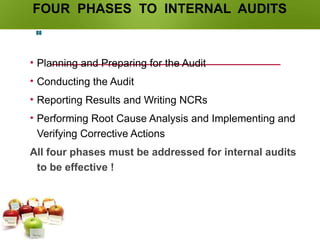

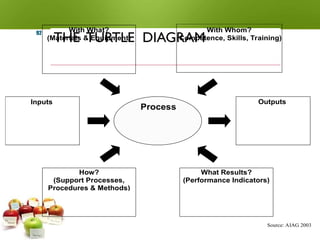

The document outlines the responsibilities and processes of internal auditors within a management system, emphasizing the requirements of ISO 9001:2015 and the importance of the Plan-Do-Check-Act (PDCA) cycle. It describes the audit management process, types of audits, and the various stages involved in preparing and conducting an audit, including collecting evidence, generating findings, and reporting results. Additionally, the document highlights the significance of auditor competence, ethical conduct, and continuous improvement in maintaining an effective quality management system.