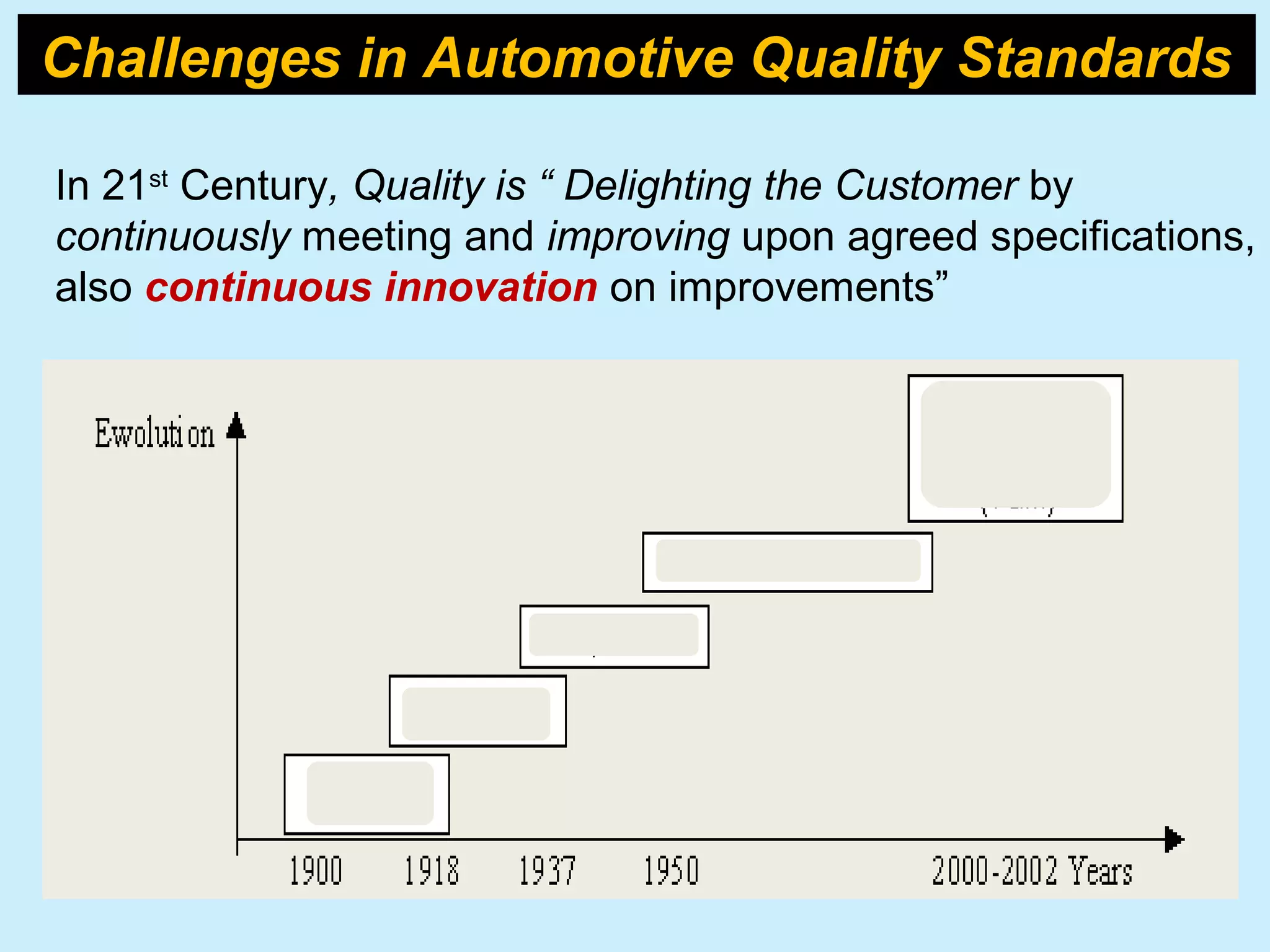

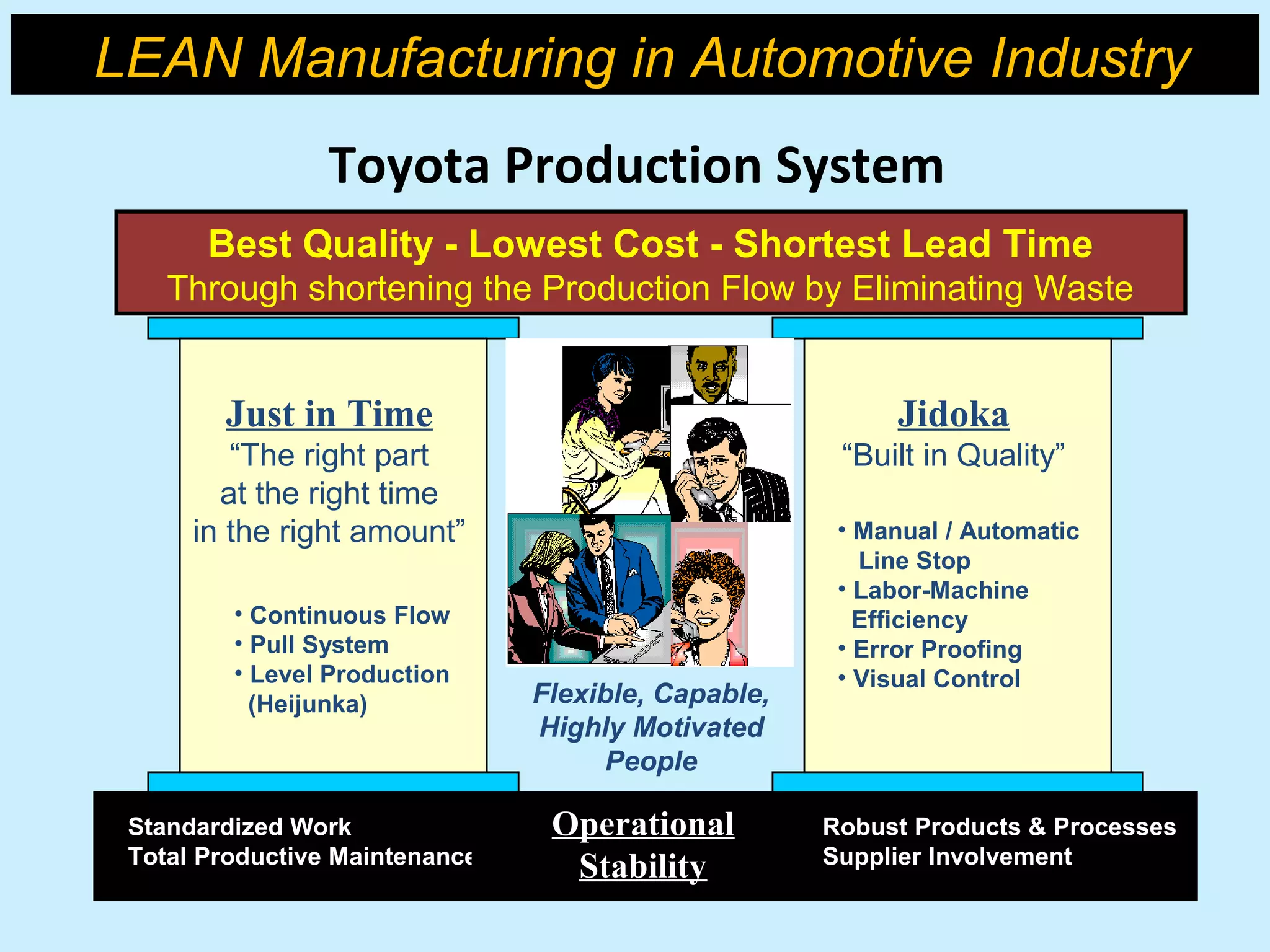

The document provides an overview of challenges in automotive quality standards and the requirements of IATF 16949. It discusses the evolution of quality management and the automotive industry. Key points include the transition from ISO/TS 16949 to IATF 16949, the six key changes in IATF 16949 including risk-based thinking and specific customer requirements, and tips for getting started with IATF 16949 certification. The presentation aims to help participants better understand quality standards for the automotive industry.