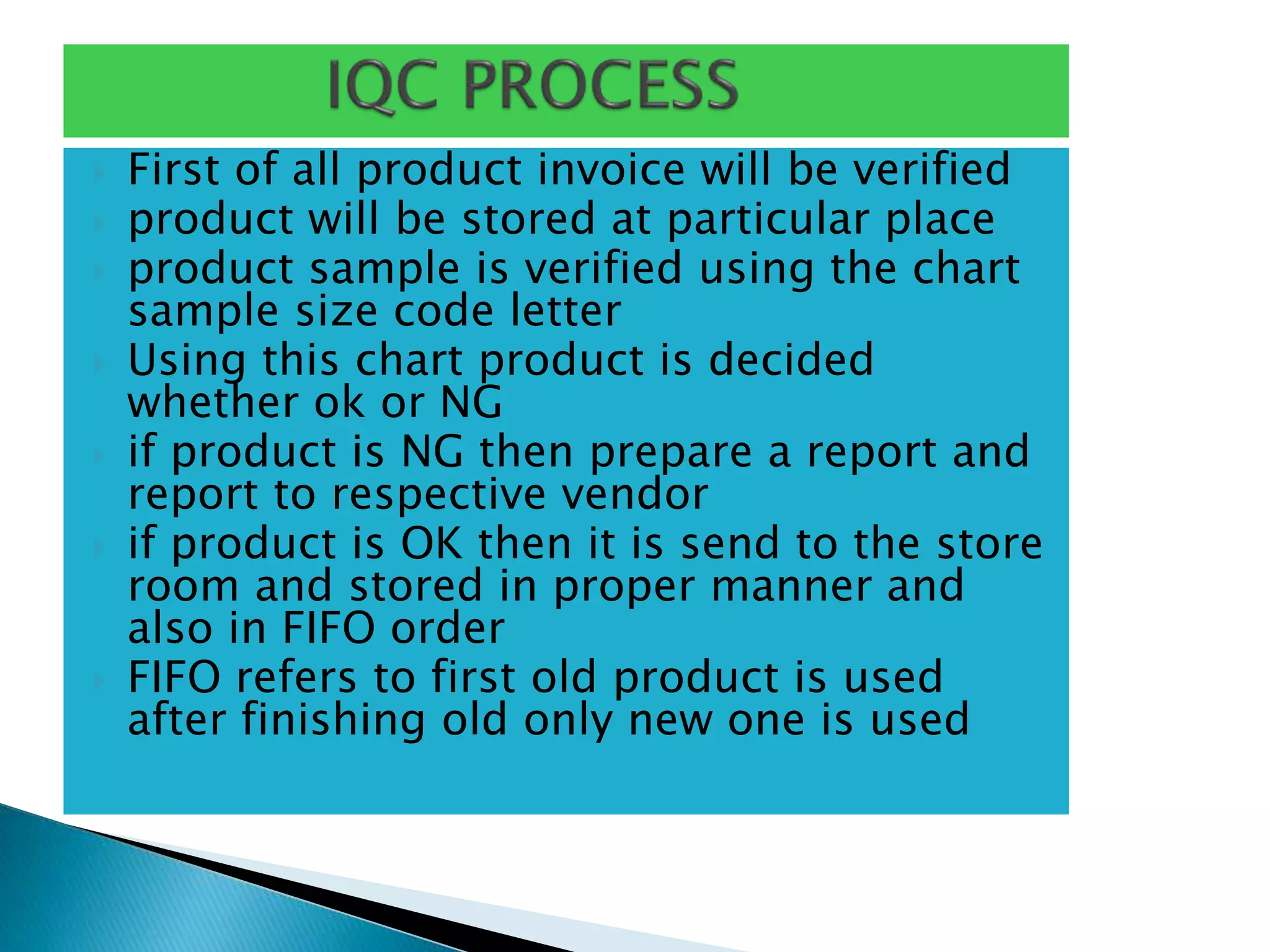

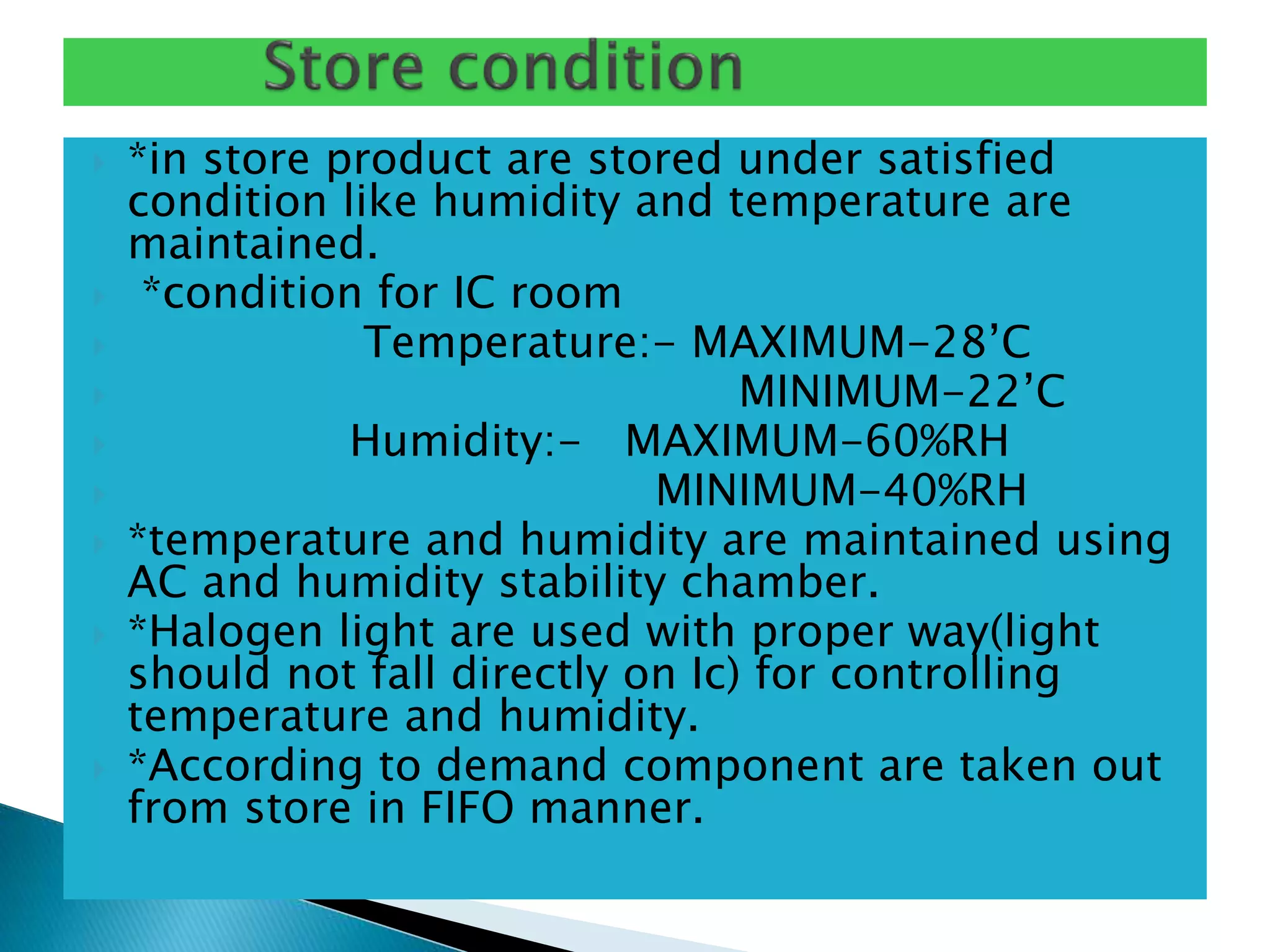

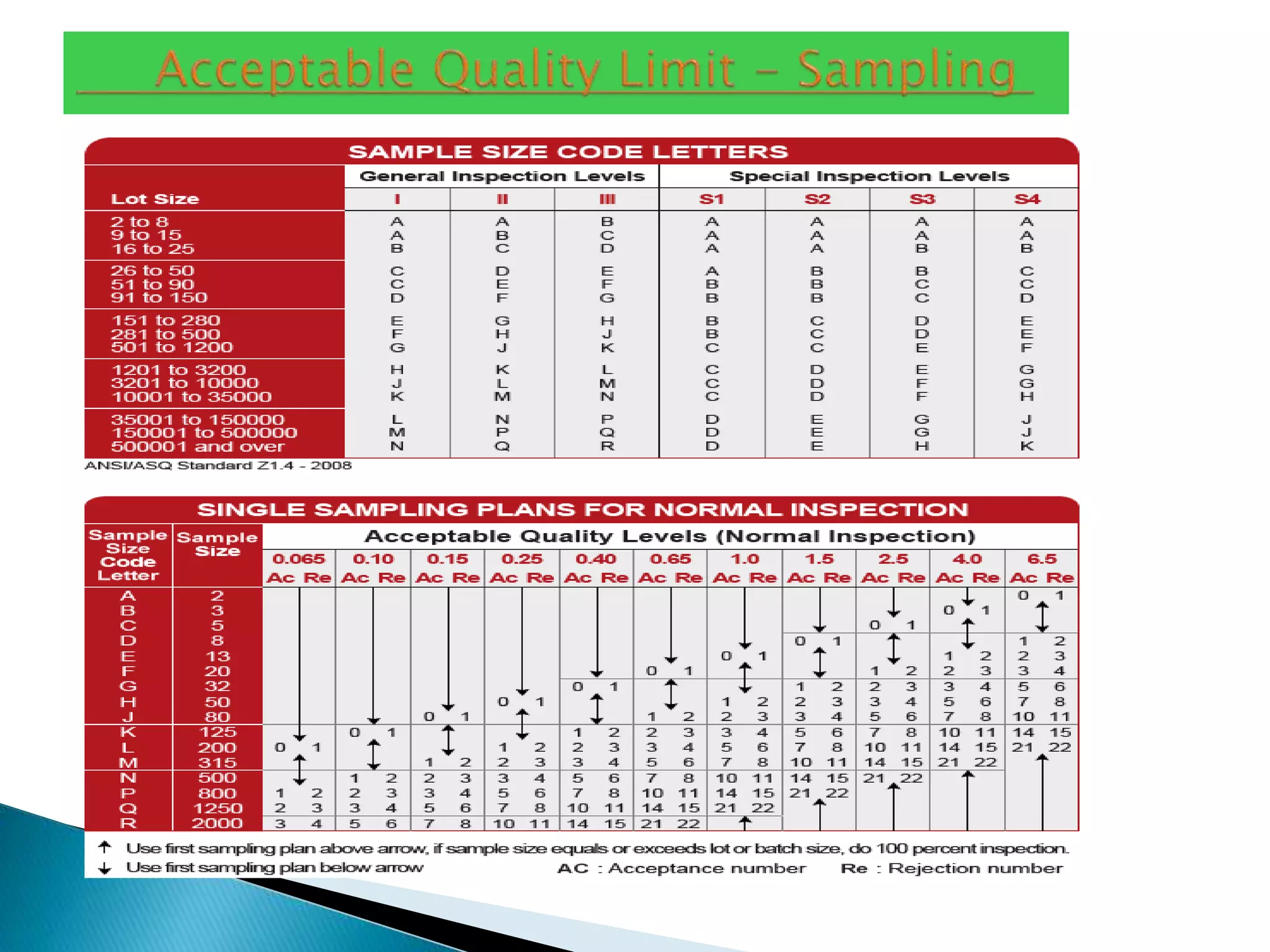

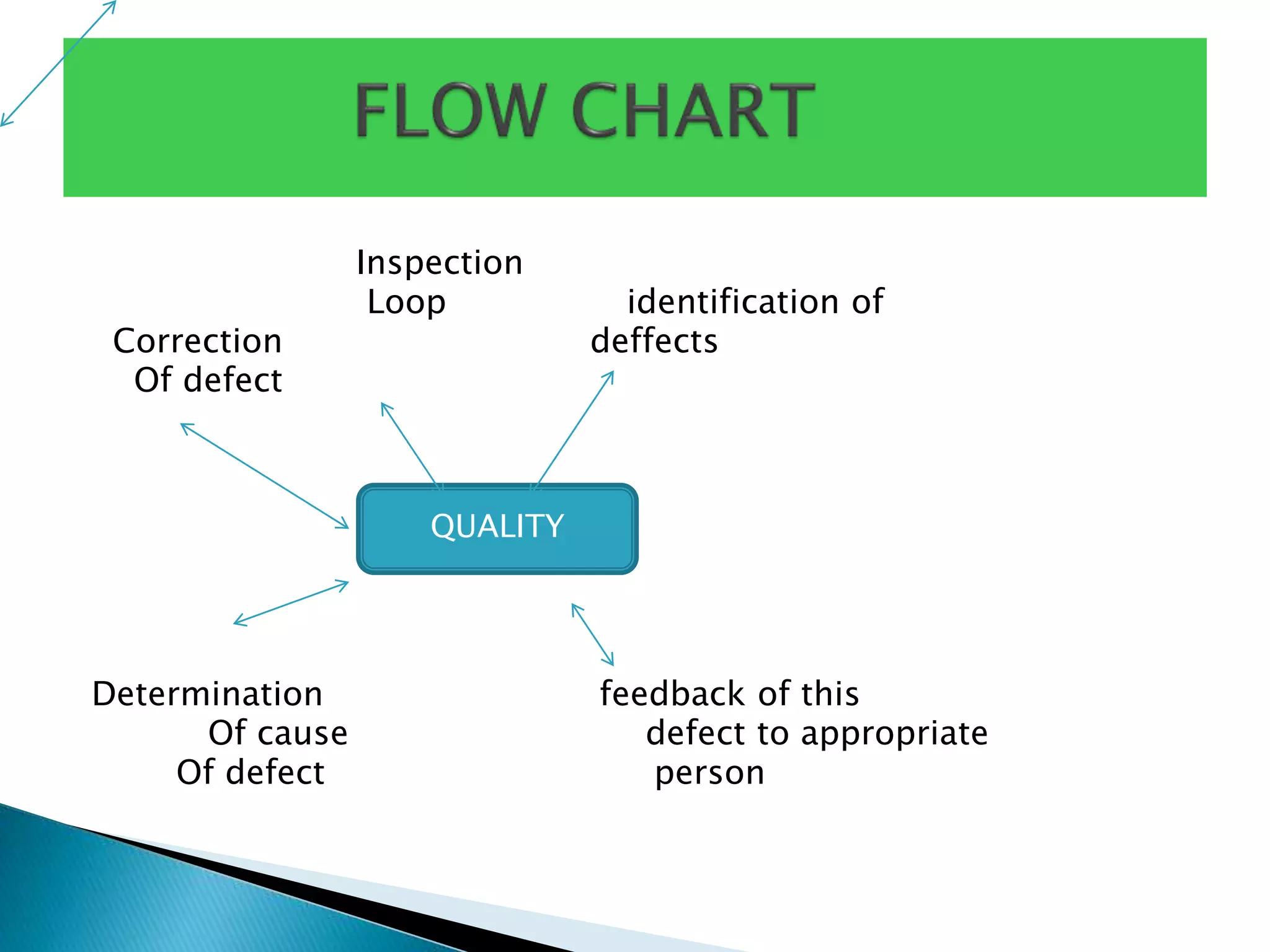

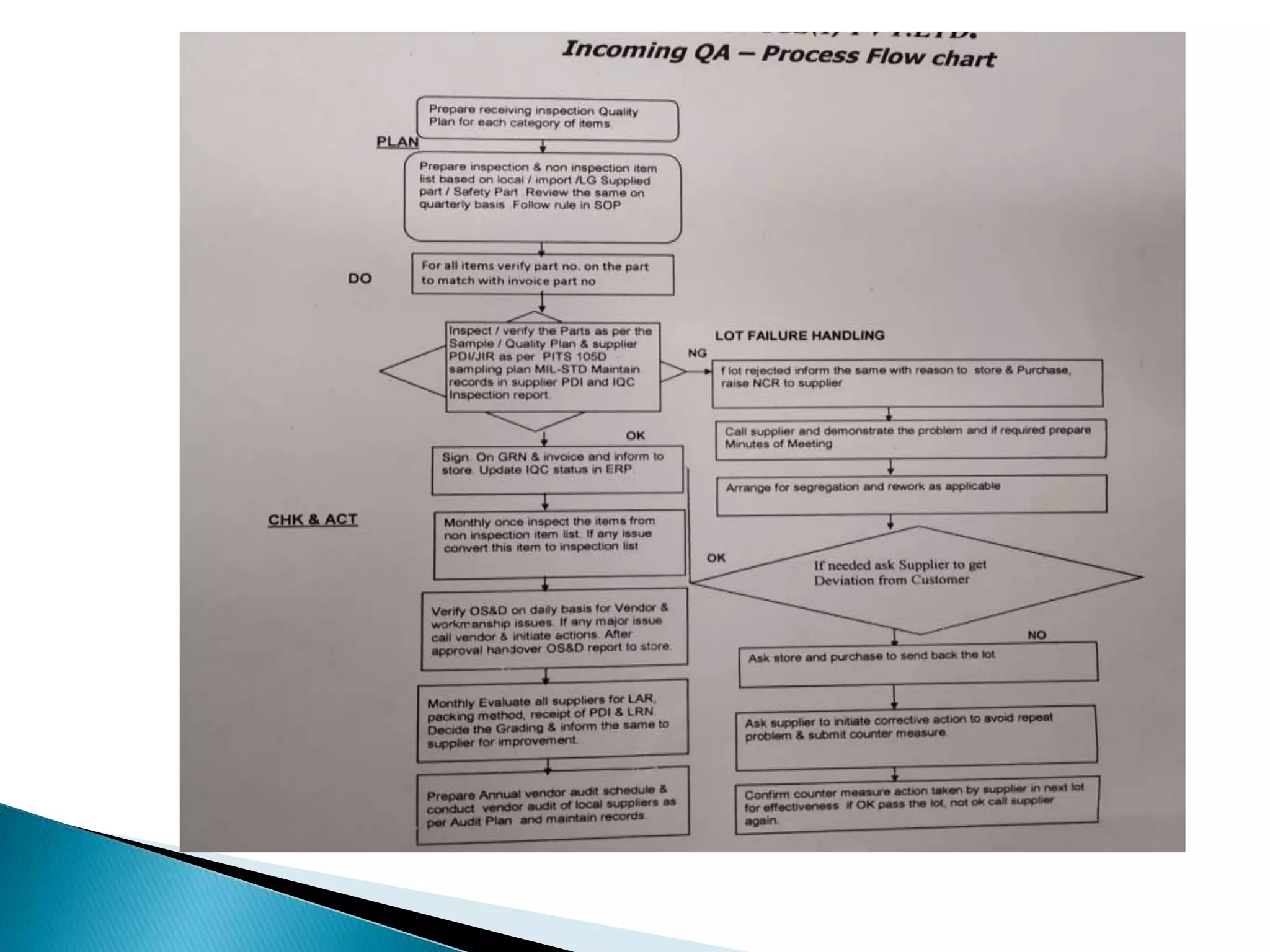

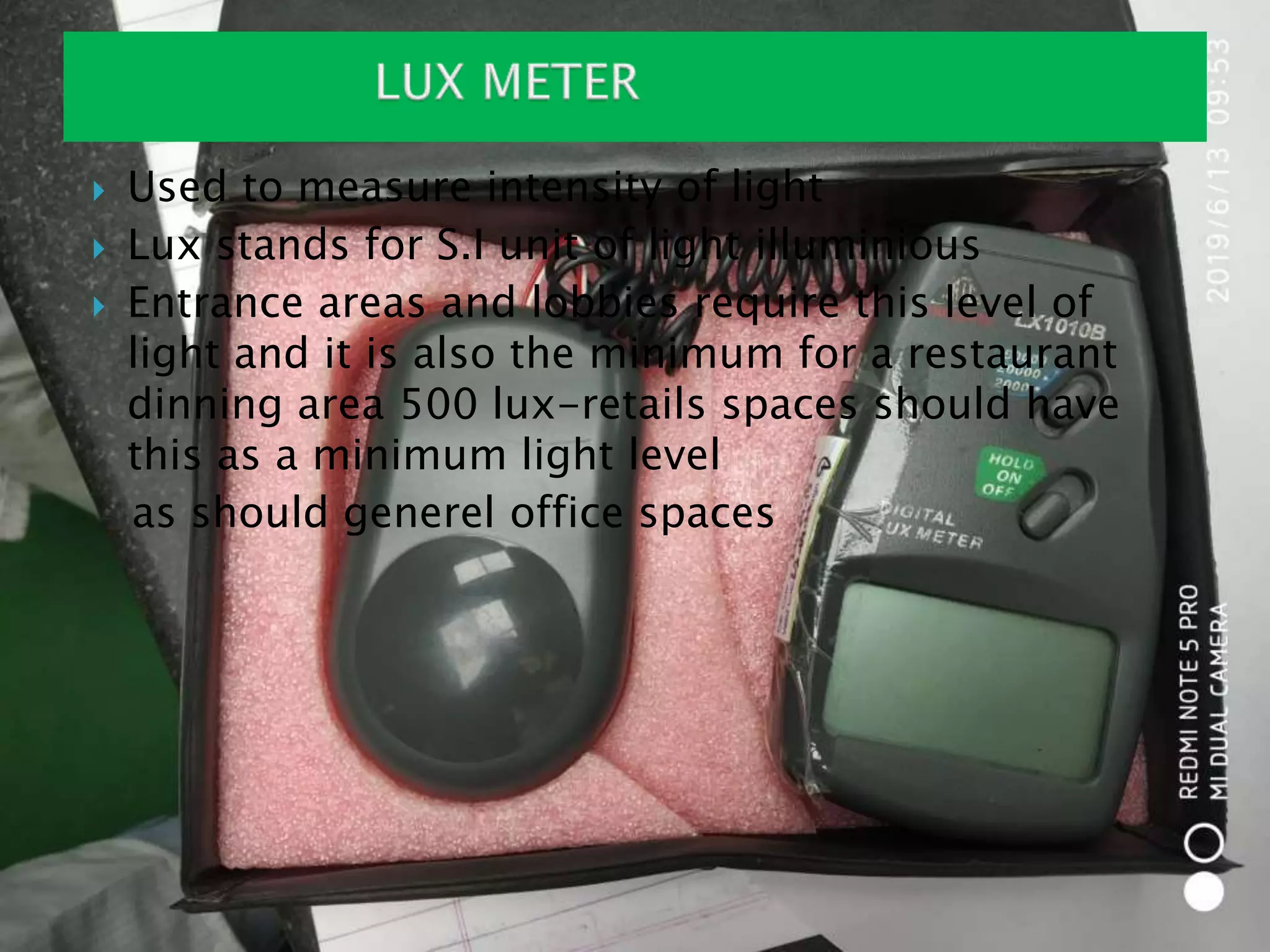

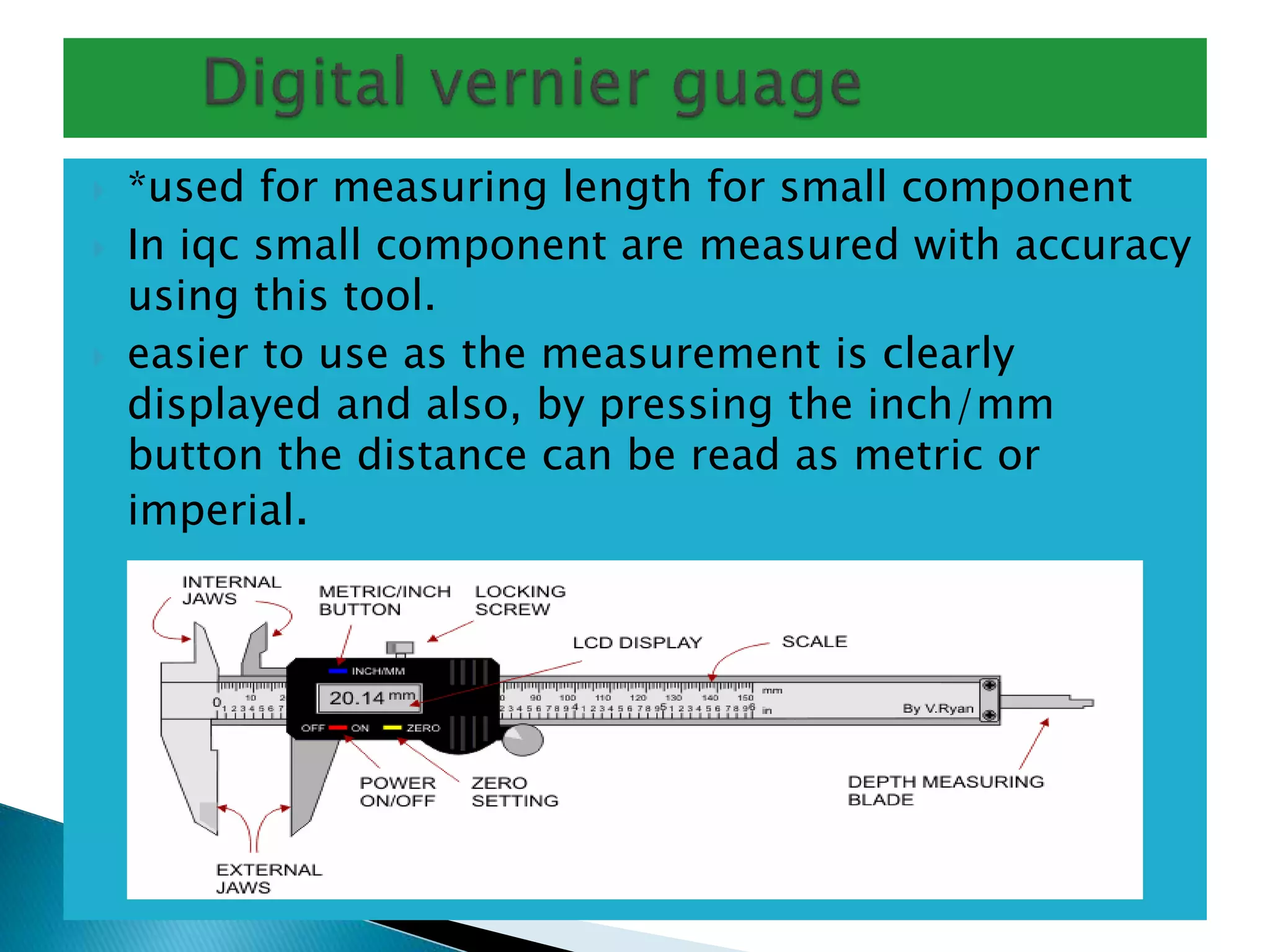

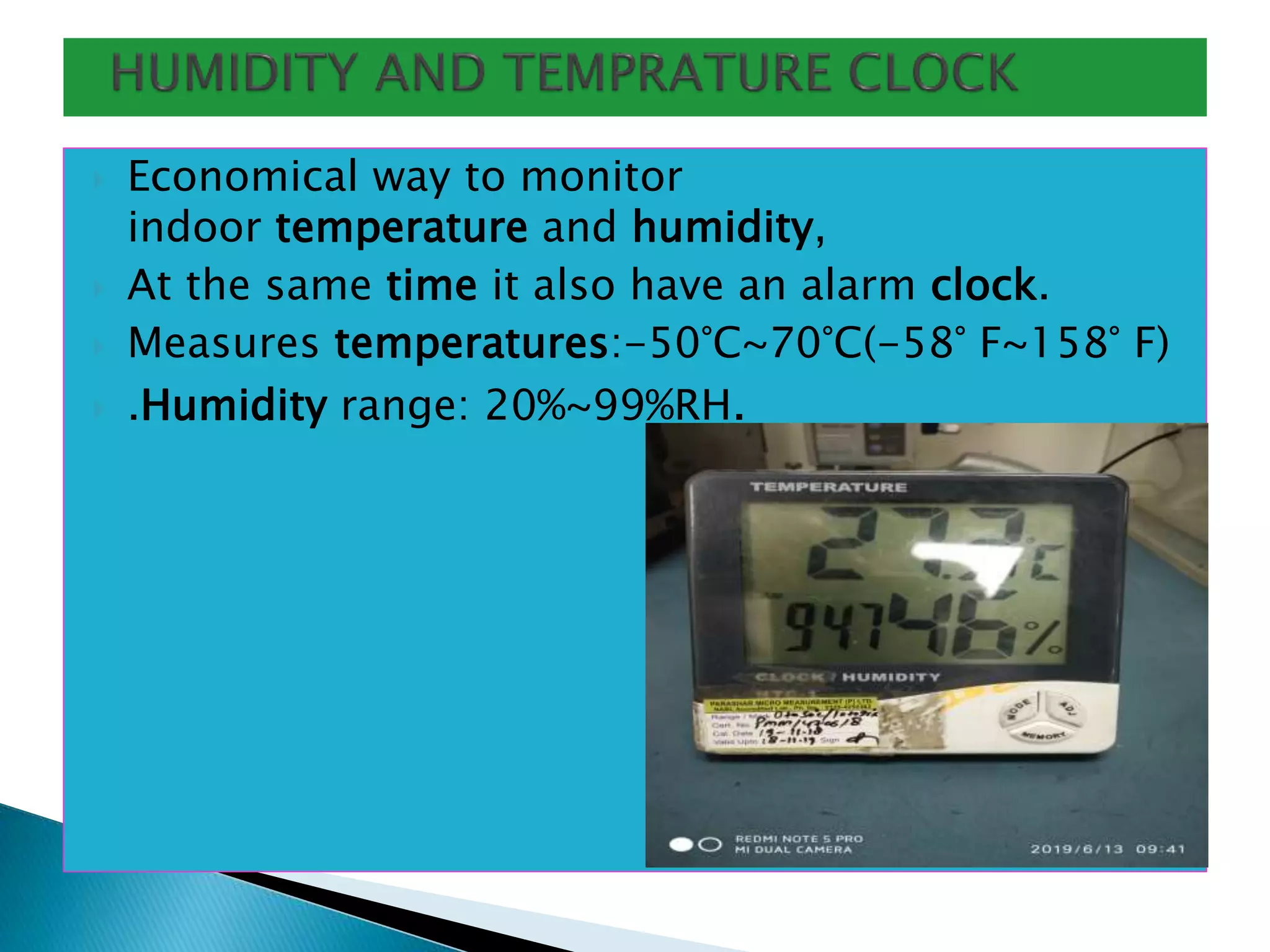

The document discusses the importance of Incoming Quality Control (IQC) in manufacturing, emphasizing the role of quality in meeting customer needs and ensuring product compliance. It outlines various tools and processes used in IQC, such as high voltage testers and digital micrometers, as well as the procedures for handling acceptable and rejected products. The document concludes by highlighting the continuous nature of quality improvement and its significance for business management.

![ known as a micrometer screw gauge, is a device

incorporating a calibrated screw widely used

for accurate measurement of

components[1] in mechanical

engineering and machining as well as most

mechanical trades,](https://image.slidesharecdn.com/iqc-incomingqualitycontrol-200530173228/75/Iqc-incoming-quality-control-18-2048.jpg)