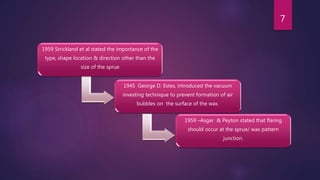

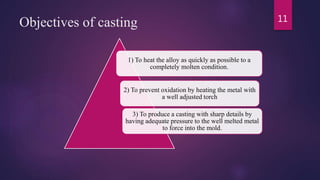

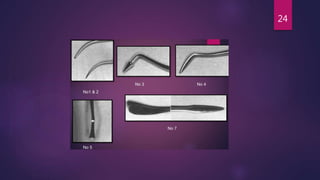

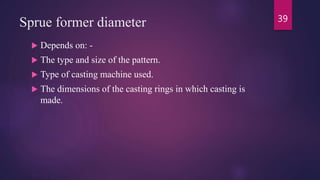

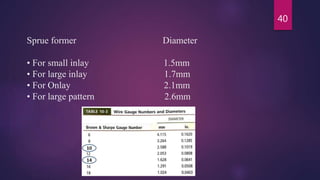

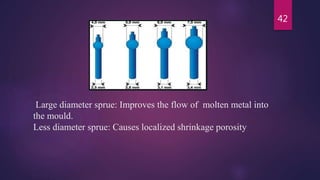

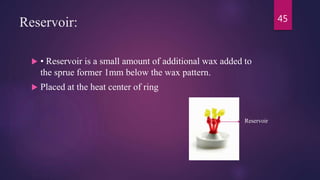

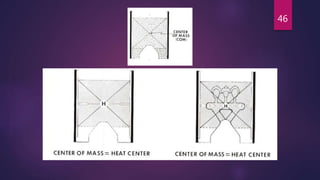

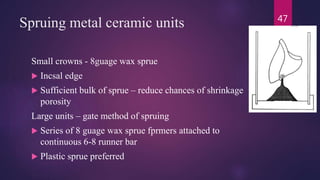

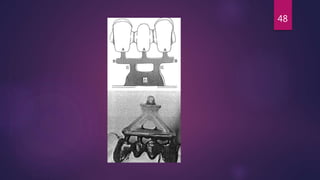

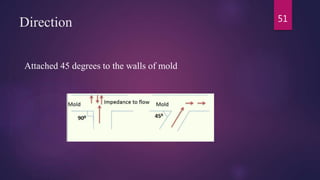

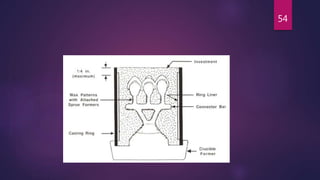

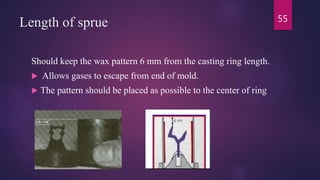

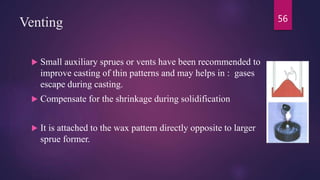

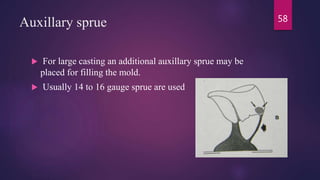

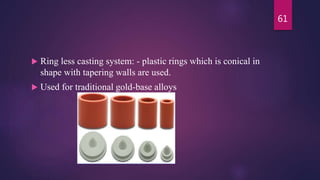

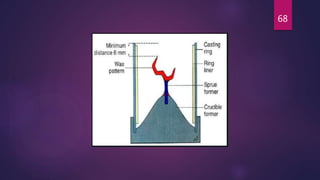

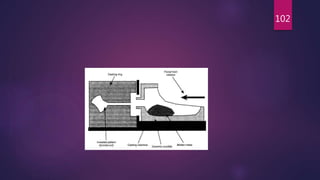

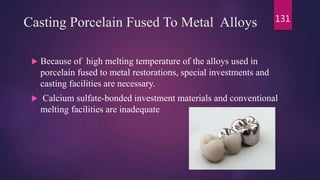

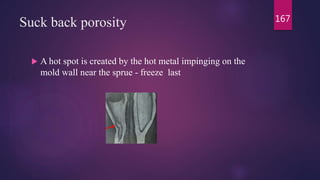

This document provides information on the casting procedure for dental restorations. It discusses the history of casting, defines key terms, and outlines the basic steps of the casting process including fabrication of the wax pattern, spruing, investing, casting, and finishing. The optimal sprue design is described, noting that the sprue should be attached to the bulkiest part of the pattern away from margins, directed at a 45 degree angle, and of a length that positions the pattern 6mm from the casting ring. Proper sprue design is important to allow gases to escape and molten metal to fully enter the mold cavity.