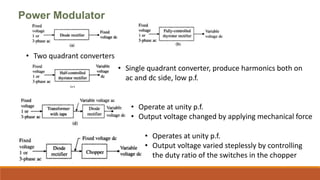

Electric drives employ electric motors to control motion. They have advantages like flexible speed control, efficiency, and adaptability. Electric drives are used in various low and high power applications from appliances to cranes and factories. An electric drive system consists of a motor, load, controller, power source, and power modulator. The power modulator converts and regulates power from the source to the motor according to the load needs. Electric drives can operate in up to four quadrants depending on the direction of rotation and whether torque aids or opposes motion. Proper selection of an electric drive depends on requirements like the power source, costs, speed and torque characteristics, and transient operation needs.