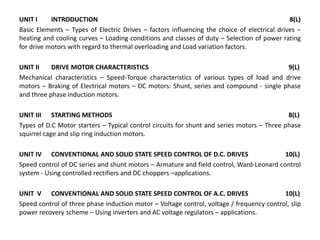

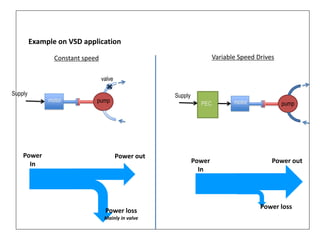

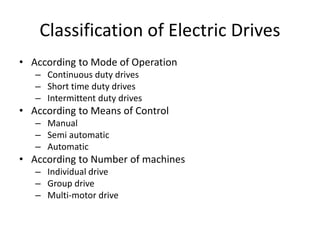

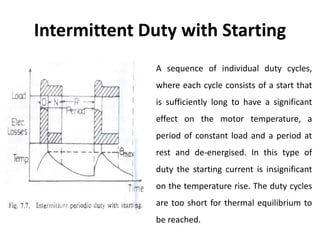

The document is an educational outline on electrical drives and controls, discussing their basic elements, motor characteristics, starting methods, and speed control techniques for both DC and AC drives. It covers classifications of electric drives, applications, advantages, and selection criteria, alongside a detailed analysis of power sources and processing units. Additionally, it emphasizes the importance of thermal management and the duty cycles pertinent to motor performance.