The px4i and px6i high performance printer user’s manual provides essential operational and service information for users of Intermec's printers. It includes details on configurations, connecting to various devices, and loading media, along with safety information and warranties. The document is proprietary and subject to change, with a recording of updates and support resources available.

![Chapter 2 — Connecting the Printer

PX4i and PX6i High Performance Printer User’s Manual 61

2 Send the following commands to permanently assign the IP

address, subnet mask, default router, and name server:

<SI>nn[,m1[,m2]]

where:

n is the IP address of the printer in the format n.n.n.n, where n is a

number from 0 to 255.

,m1 is the subnet mask address in the format n.n.n.n, where n is a

number from 0 to 255.

,m2 is the router address in the format n.n.n.n, where n is a

number from 0 to 255.

3 Disconnect the printer from the PC.

4 On your PC, enter the IP address of the printer in the address field

of your web browser (for example http://10.200.27.94) and press

Enter.

The home page of the printer appears.

Setting Up 802.11 Radio Communications

If your printer has an optional 802.11 b/g radio, you can transfer and

receive data using wireless communications. This manual assumes

that you have already set up your wireless communications network

including your access points. This section describes how to set up

wireless security on your printer.

The printer supports these authentication modes:

• none

• WEP (64 bit and 128 bit)

• WPA Personal and Enterprise mode (802.1x authentication)

• WPA2 Personal and Enterprise mode (802.1x authentication)

Note: You must specify at least two of the three parameters for the

command to take effect.

Note: WPA and WPA2 Enterprise mode currently support PEAP,

TTLS, LEAP, and EAP-FAST. For LEAP authentication, the printer

supports Open EAP, but does not support Network EAP.](https://image.slidesharecdn.com/intermecpx4ipx6irfidbarcodeprinterusermanualhionit-190724044315/85/Intermec-PX4i-PX6i-RFID-75-320.jpg)

![Chapter 3 — Configuring the Printer

80 PX4i and PX6i High Performance Printer User’s Manual

Configuring Web Shell Settings

Use the Web Shell page to view and change test and default settings.

You can also use the Web Shell page to print test labels and change the

command language.

To configure Web Shell settings

1 Click Printer > Web Shell.

2 Select the action you want to take or the setting you want to

change.

• For the actions in the top of the screen, the printer performs

the action and may prompt you to reboot the printer.

• For the settings in the bottom of the screen, select the settings

you want and click Submit Setup. A message appears stating,

“Application change will take effect at reboot.” You can select

Reboot or wait until you are done making other configuration

changes.

Use the following table to understand the Web Shell settings.

Understanding the Web Shell Settings

Setting Description

Testfeed [value] Calibrates the label stop sensor performs a testfeed.

Selecting this setting is equivalent to issuing the

TESTFEED command on the printer.

Ribbon Sensor

[value]

Detects if the printer runs out of ribbon during printing.](https://image.slidesharecdn.com/intermecpx4ipx6irfidbarcodeprinterusermanualhionit-190724044315/85/Intermec-PX4i-PX6i-RFID-94-320.jpg)

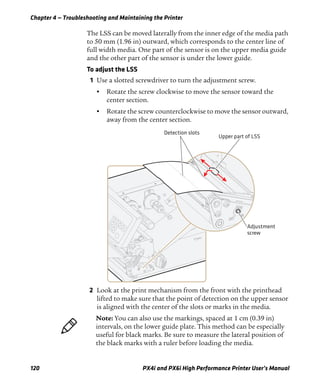

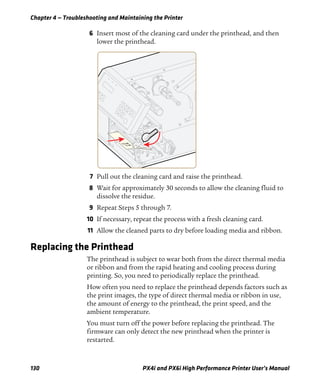

![Chapter 4 — Troubleshooting and Maintaining the Printer

126 PX4i and PX6i High Performance Printer User’s Manual

Follow these guidelines for cleaning the printer:

• Always remove the power cord before cleaning.

• Never spray the printer. Protect it from water when cleaning the

premises.

• Never use any sharp tools for removing stuck labels. The printhead

and rollers are delicate.

Cleaning the Exterior of the Printer

Clean the exterior of the printer as needed.

To clean the exterior of the printer

• Wipe external surfaces with a soft cloth slightly moistened with

water or a mild detergent.

Cleaning the Media Guides

The label stop sensor, which controls the media feed, is covered by two

plastic guides. The guides are transparent to allow the light to pass

between the two parts of the label stop sensor. These areas must be

kept clean from dust, stuck labels, and adhesive residue.

If your printer starts to feed labels in an unexpected way, pull out

the upper guide check for objects, such as dust, adhesive residue, or

labels, that may be blocking the beam of light. If necessary, clean the

guides.

Use only the cleaning agents specified in this section. Intermec is

not responsible for damage caused by any other cleaning

materials used on this printer. Clean the printer with a cotton

swab saturated with alcohol.

When cleaning or replacing the printhead, take precautions to

avoid electrostatic discharges.

Isopropyl alcohol [(CH 3)2CHOH; CAS 67-63-0] is a highly

flammable, moderately toxic, and mildly irritating substance.](https://image.slidesharecdn.com/intermecpx4ipx6irfidbarcodeprinterusermanualhionit-190724044315/85/Intermec-PX4i-PX6i-RFID-140-320.jpg)

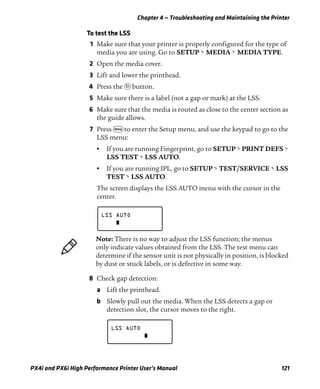

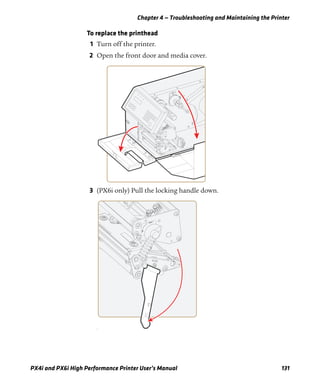

![Chapter 4 — Troubleshooting and Maintaining the Printer

128 PX4i and PX6i High Performance Printer User’s Manual

3 Press the snap-lock, lift the edge of the lower guide, and pull the

lower guide straight out.

4 Clean the guides with a cleaning card or a soft cloth soaked in

isopropyl alcohol. Be careful not to scratch the guides.

5 Replace the upper and lower guides.

Cleaning the Printhead

Cleaning the printhead on a regular basis is important for the life of

the printhead and for the printout quality. You should clean the

printhead each time you replace the media. This section describes how

to clean the printhead using cleaning cards. If additional cleaning is

required, for example removing adhesive residue from the platen

roller or tear bar, use a cotton swab moistened with isopropyl alcohol.

Isopropyl alcohol [(CH 3)2CHOH; CAS 67-63-0] is a highly

flammable, moderately toxic, and mildly irritating substance.](https://image.slidesharecdn.com/intermecpx4ipx6irfidbarcodeprinterusermanualhionit-190724044315/85/Intermec-PX4i-PX6i-RFID-142-320.jpg)

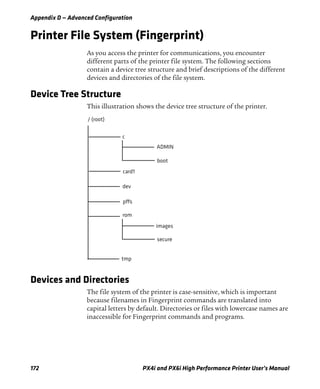

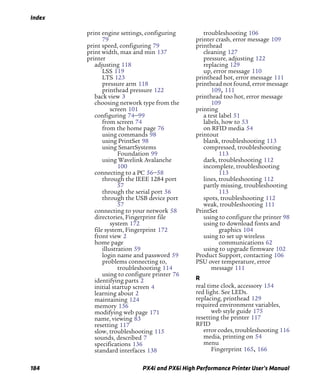

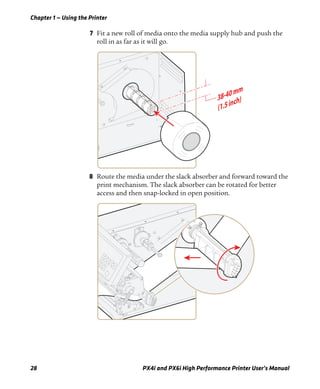

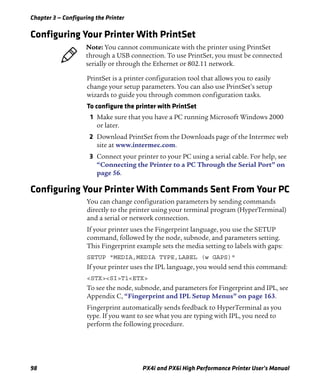

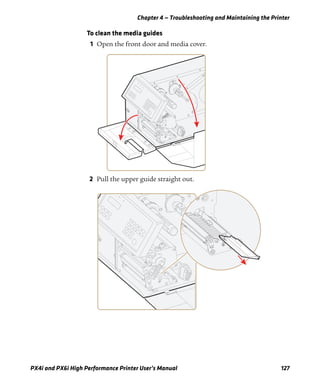

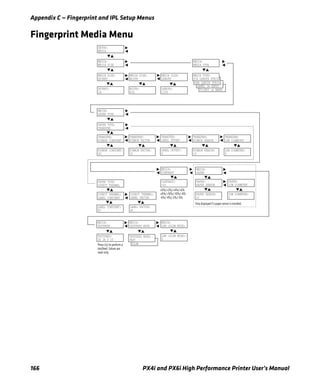

![Appendix C — Fingerprint and IPL Setup Menus

PX4i and PX6i High Performance Printer User’s Manual 167

Fingerprint Print Defs Menu

CMD LANGUAGE:

DSim

CMD LANGUAGE:

ZSim

CMD LANGUAGE:

IPL

CLIP DEFAULT:

OFF

TESTPRINT:

NETWORK INFO

TESTPRINT:

RFID TEST LABEL

TESTPRINT:

HARDWARE INFO

TESTPRINT:

SETUP INFO

TESTPRINT:

BAR CODES #2

TESTPRINT:

BAR CODES #1

TESTPRINT:

CHESS

PRINT DEFS:

TESTPRINT

LTS:

LTS ADJUST

LTS:

LTS TEST

LTS:

LTS VALUE

LTS VALUE:

10

TESTPRINT:

DIAMONDS

PRINT DEFS:

PRINT SPEED

PRINT DEFS:

LSS TEST

PRINT SPEED:

100

LSS TEST:

LSS MANUAL

LSS [G: 1]D: 13

REMOVE LABEL

ENTER TO STOP

REMOVE LABEL AND

PRESS ENTER

SETUP:

PRINT DEFS

PRINT DEFS:

HEAD RESIST

HEAD RESIST:

nnn

LSS TEST:

LSS AUTO

LSS AUTO:

Toggle between

gain (G) and drive (D)

Decrease or increase

value in brackets

PRINT DEFS:

LTS

SENSITIVITY 10

OUT OF 9-10

PRINT DEFS:

CMD LANGUAGE

PRINT DEFS:

CLIP DEFAULT

CLIP DEFAULT:

ON CMD LANGUAGE:

Direct Protocol

CMD LANGUAGE:

Fingerprint

Only displayed if a paper sensor is installed.](https://image.slidesharecdn.com/intermecpx4ipx6irfidbarcodeprinterusermanualhionit-190724044315/85/Intermec-PX4i-PX6i-RFID-183-320.jpg)