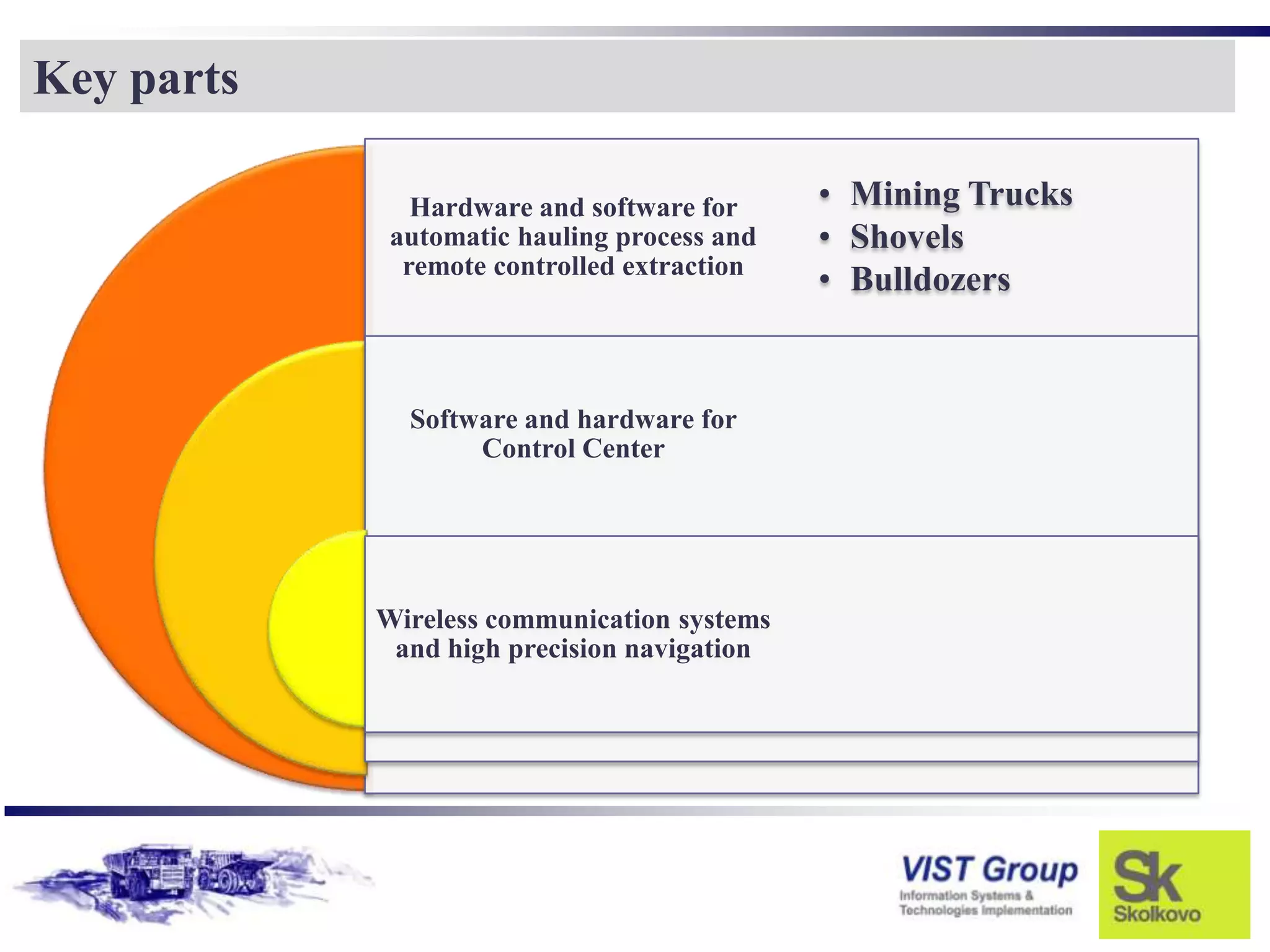

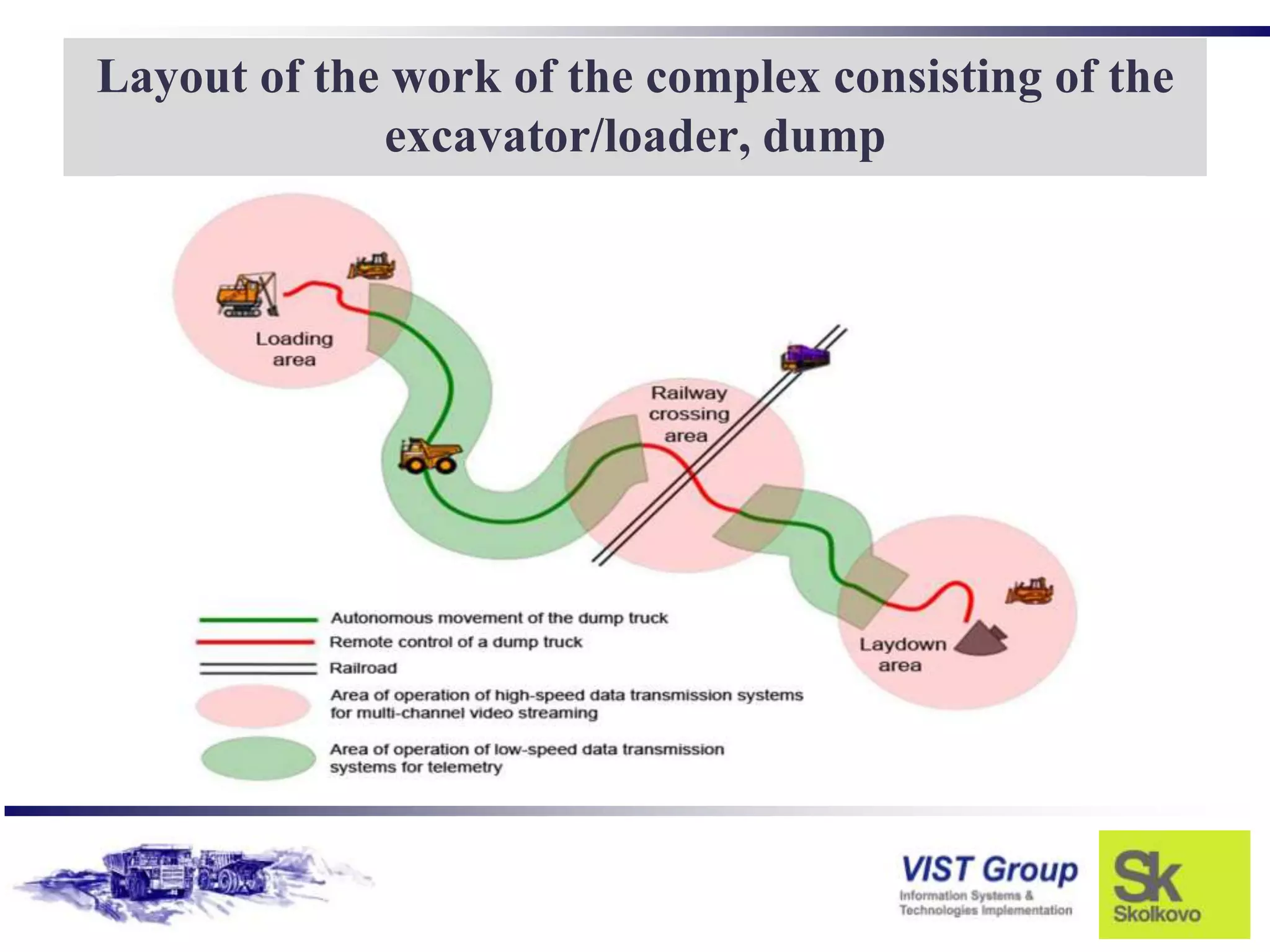

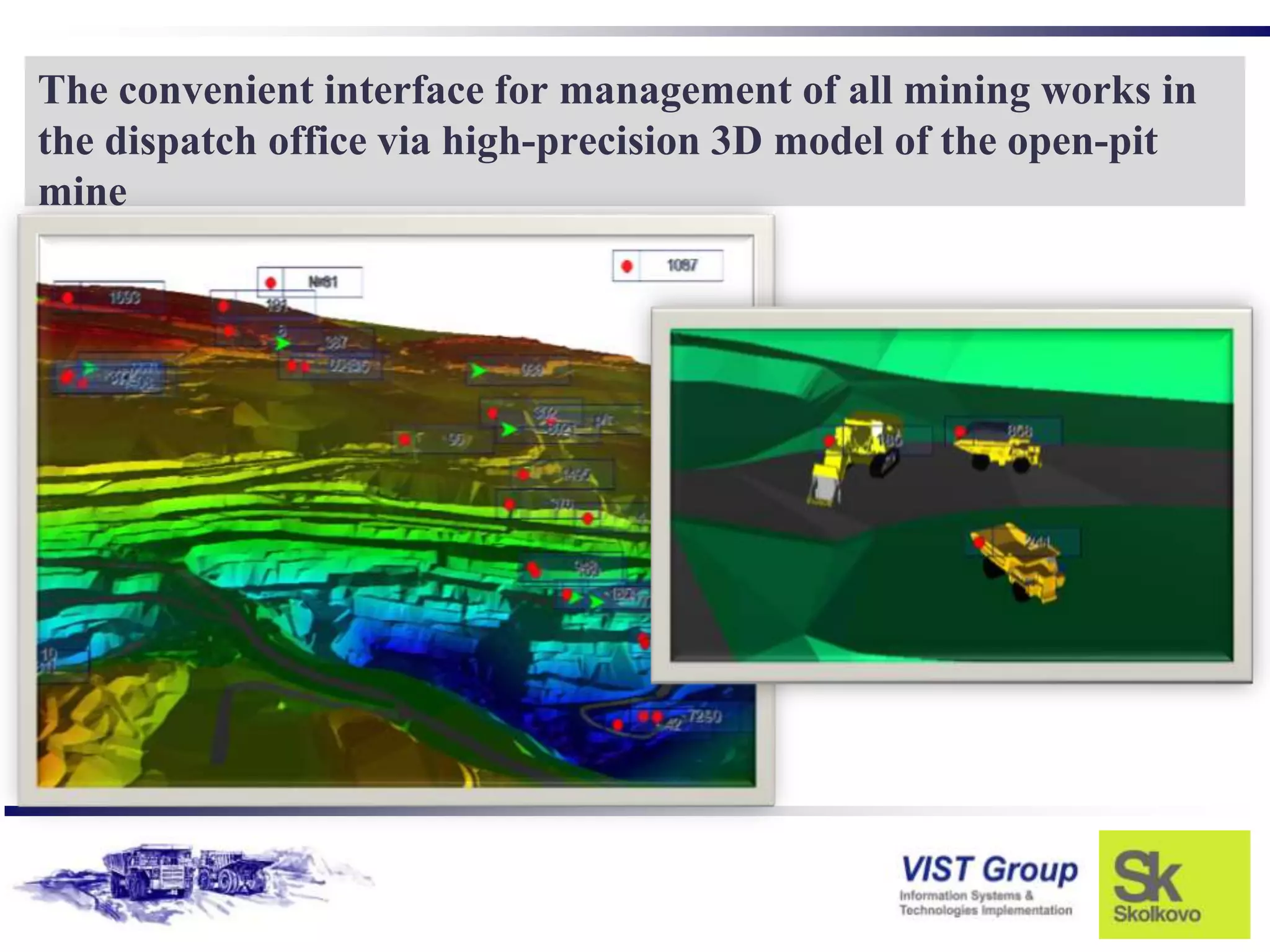

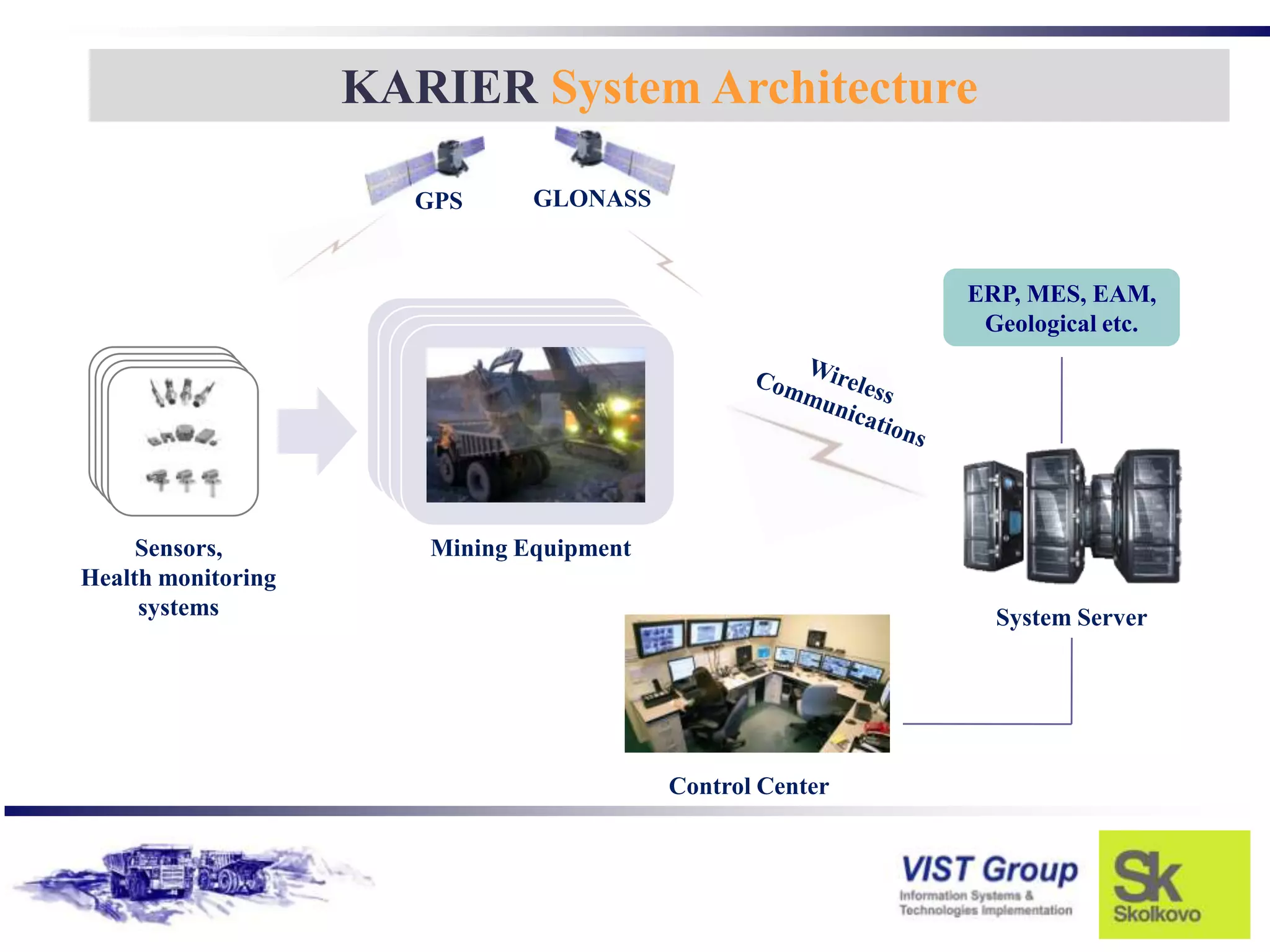

The document discusses Intelligent Mine, an unmanned technology solution for open-pit mining operations. The system uses hardware, software, and wireless communication to allow remote control of mining equipment from a control center. This increases productivity by 15-20% and allows operations in remote or harsh areas while reducing costs. Key technologies include automatic hauling processes and navigation systems. A Russian company called VIST Group provides Intelligent Mine and has implemented the system at several mining customers in Russia and CIS countries.