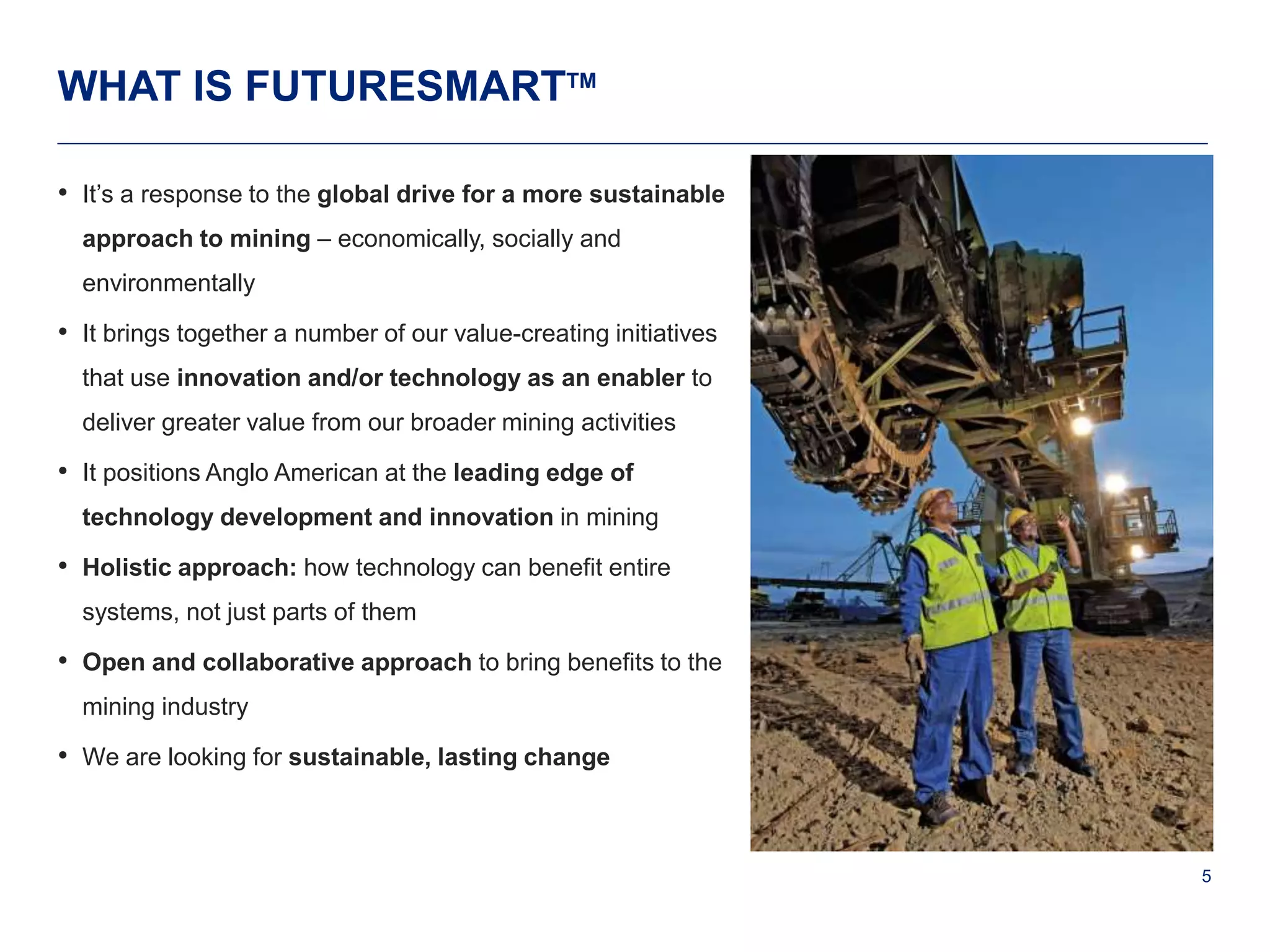

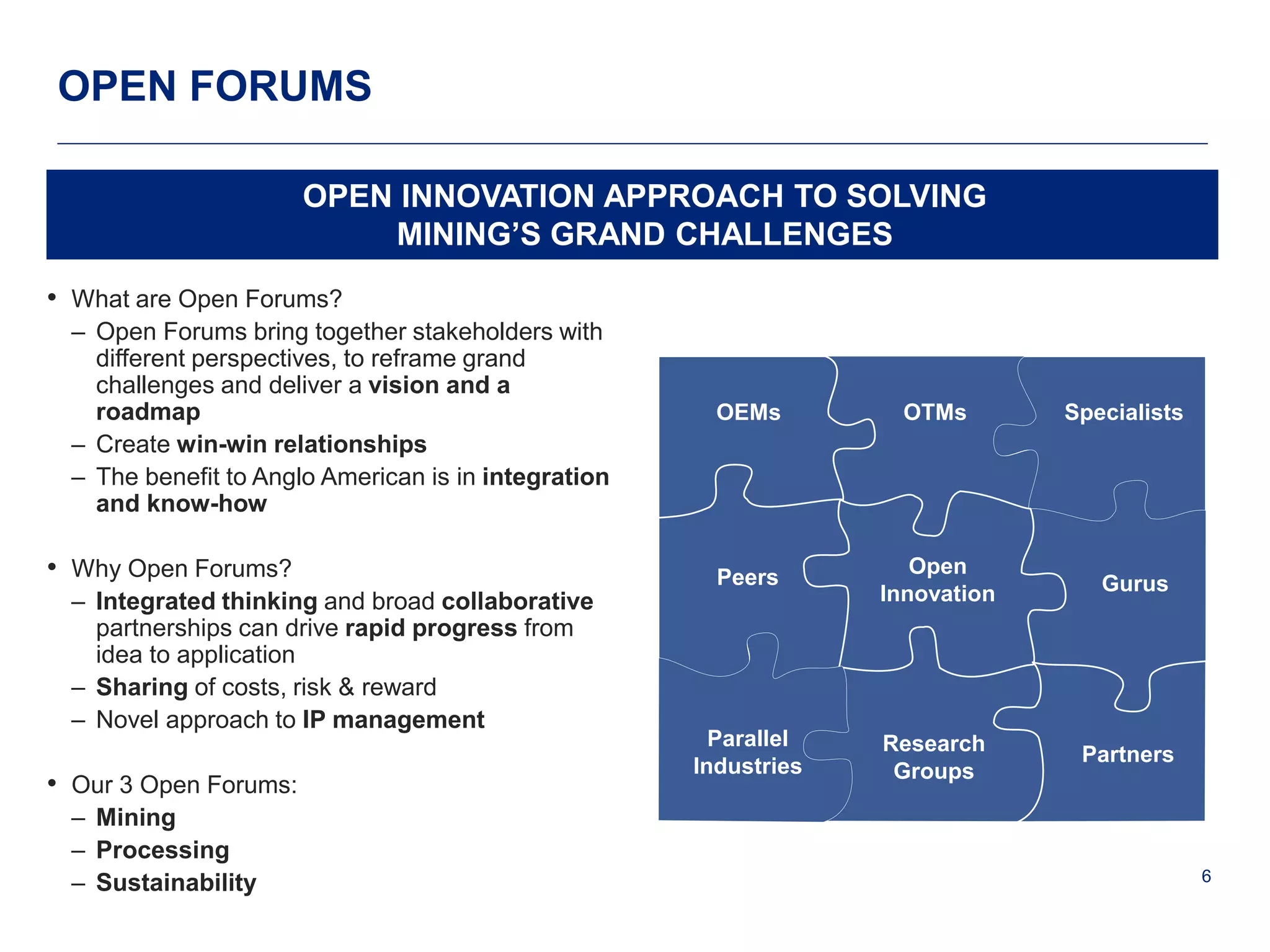

This document outlines a presentation by Donovan Waller on innovative approaches to mining, highlighting the need for radical transformation in the industry due to lagging R&D and productivity. It introduces the FuturesmartTM initiative, which aims to create sustainable mining practices through technology and collaborative efforts among stakeholders. The document also discusses open forums designed to integrate diverse perspectives, fostering innovation in mining, processing, and sustainability.