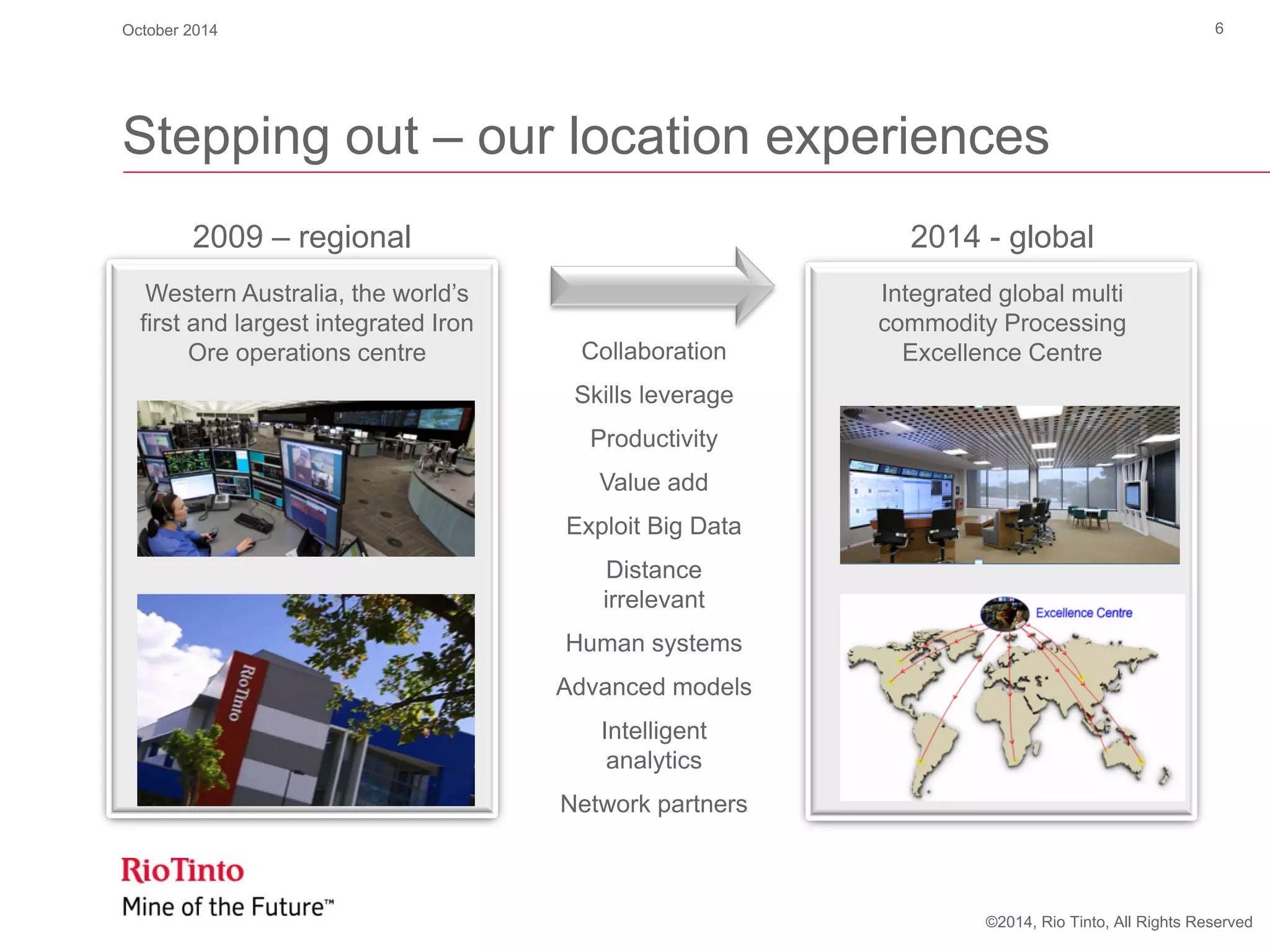

1. The document is a presentation given by John McGagh, Head of Innovation at Rio Tinto, at the Internet of Things World Forum in Chicago in October 2014.

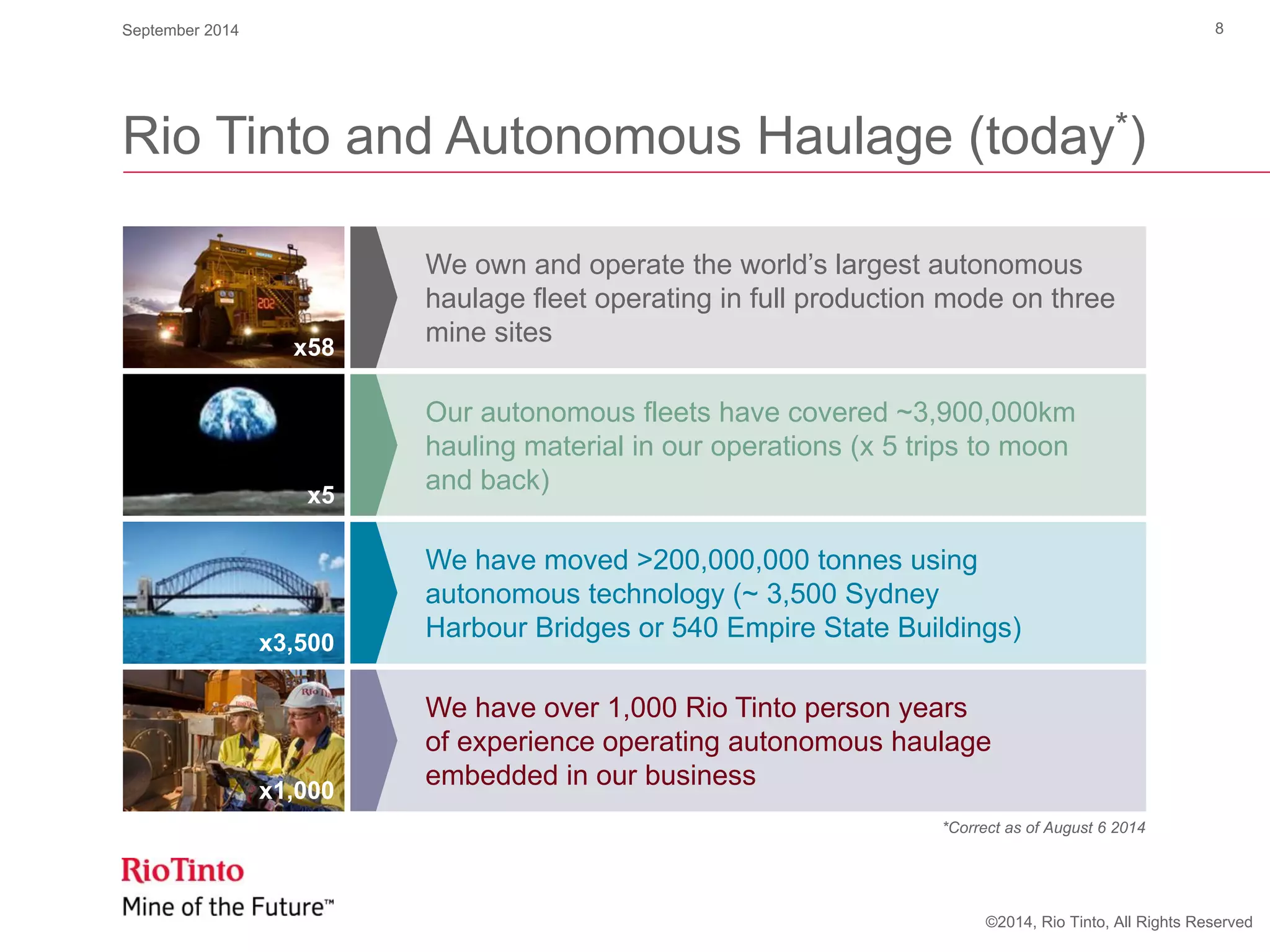

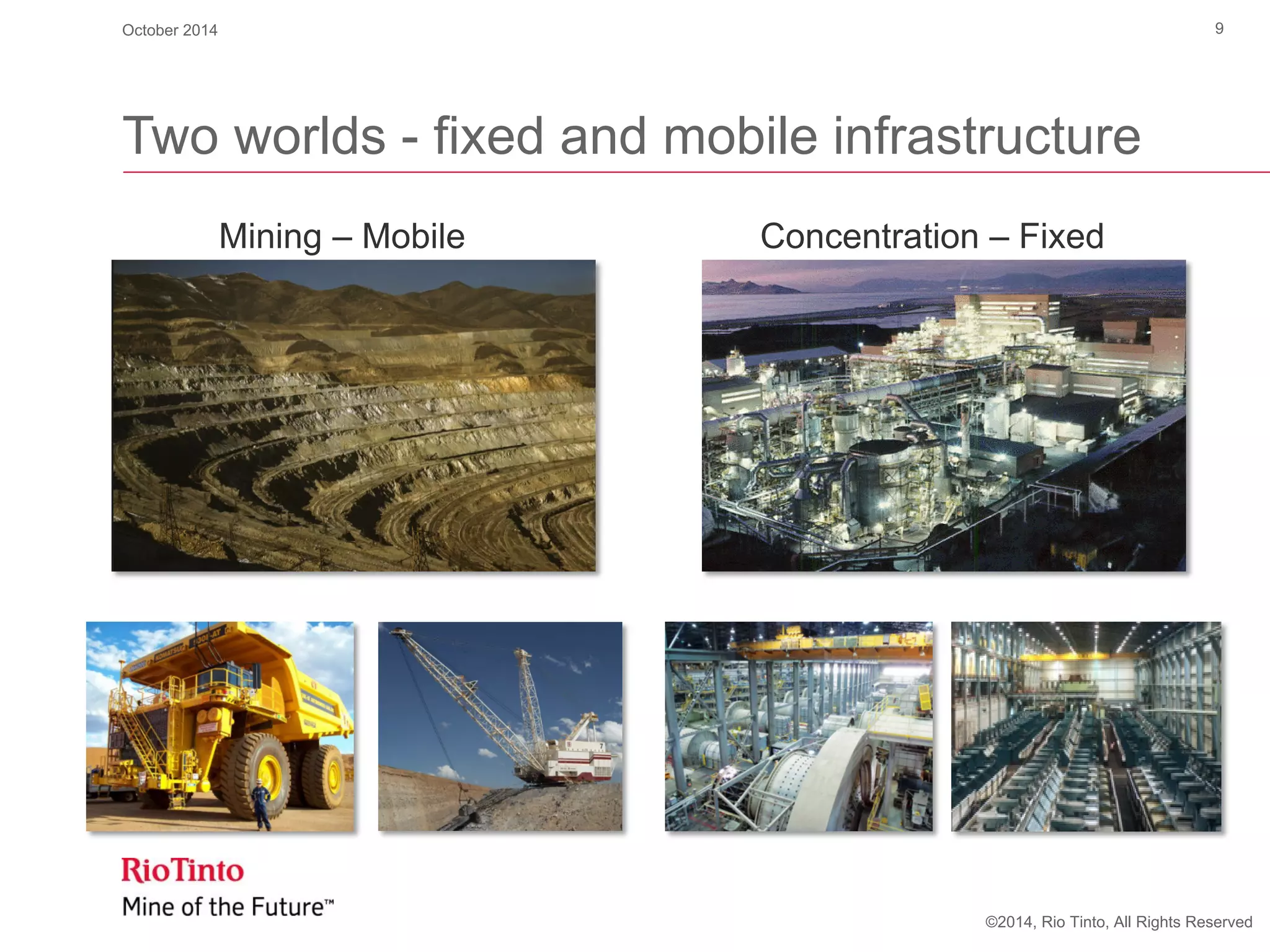

2. McGagh addressed three main points in his presentation: how mining is physically connected to ore bodies, how new connectivity provides opportunities to improve mining operations, and Rio Tinto's strategy around an "Internet of big things" through its Mine Automation System (MAS) which integrates data from fixed and mobile assets.

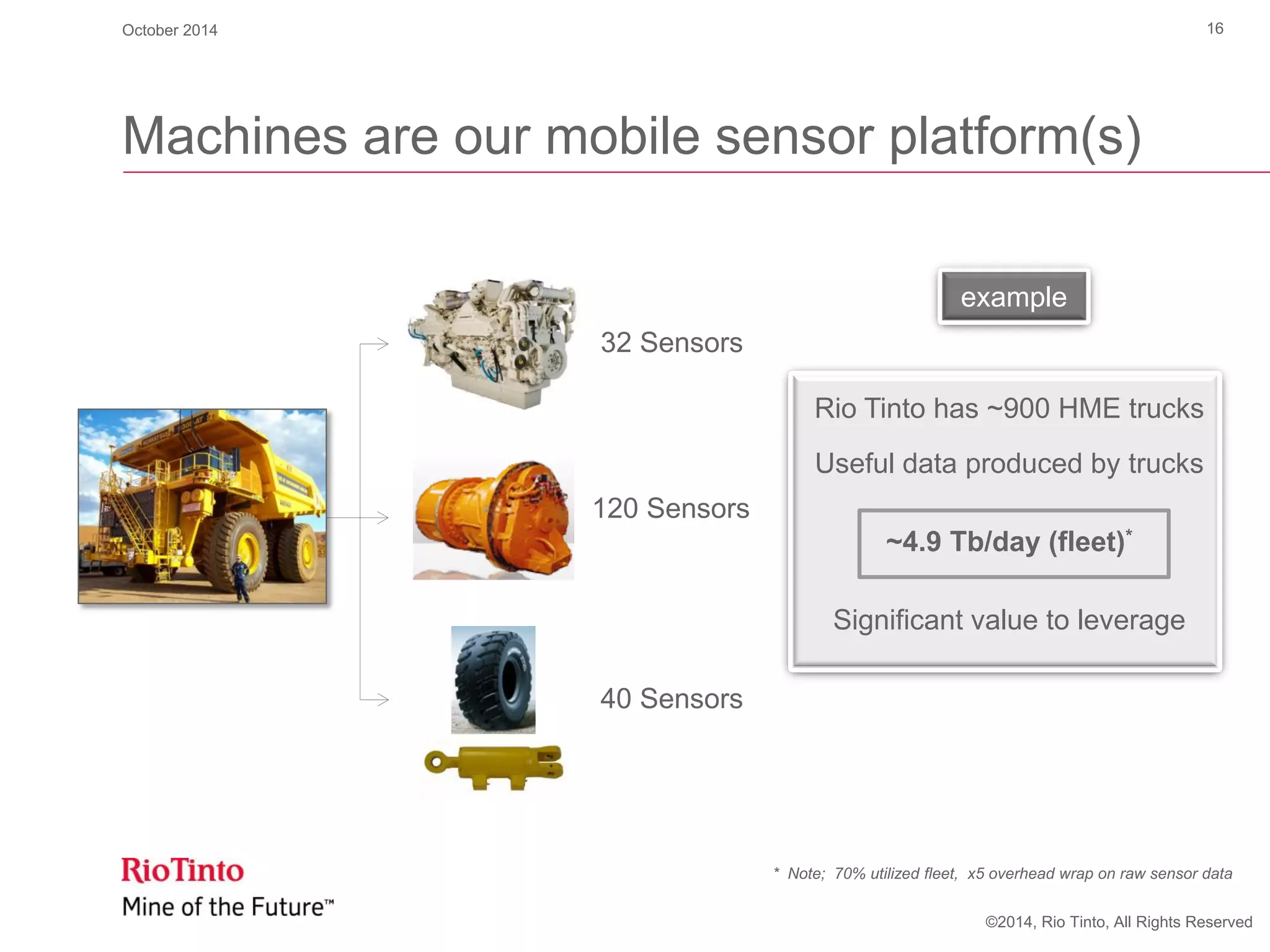

3. MAS aims to leverage data from Rio Tinto's large fleet of autonomous trucks and other machines to improve shorter-term decision making through its "sense, think, act" approach.