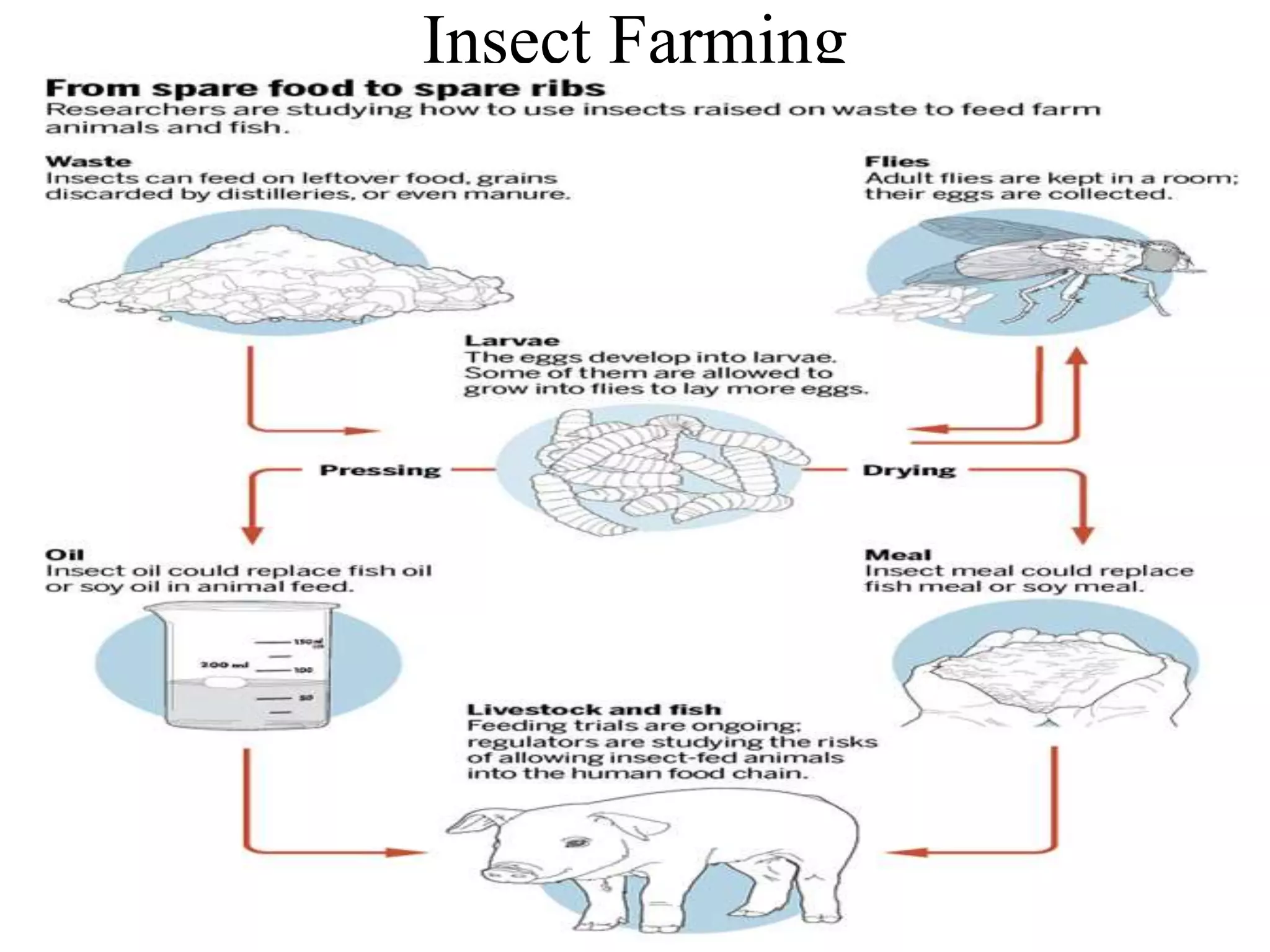

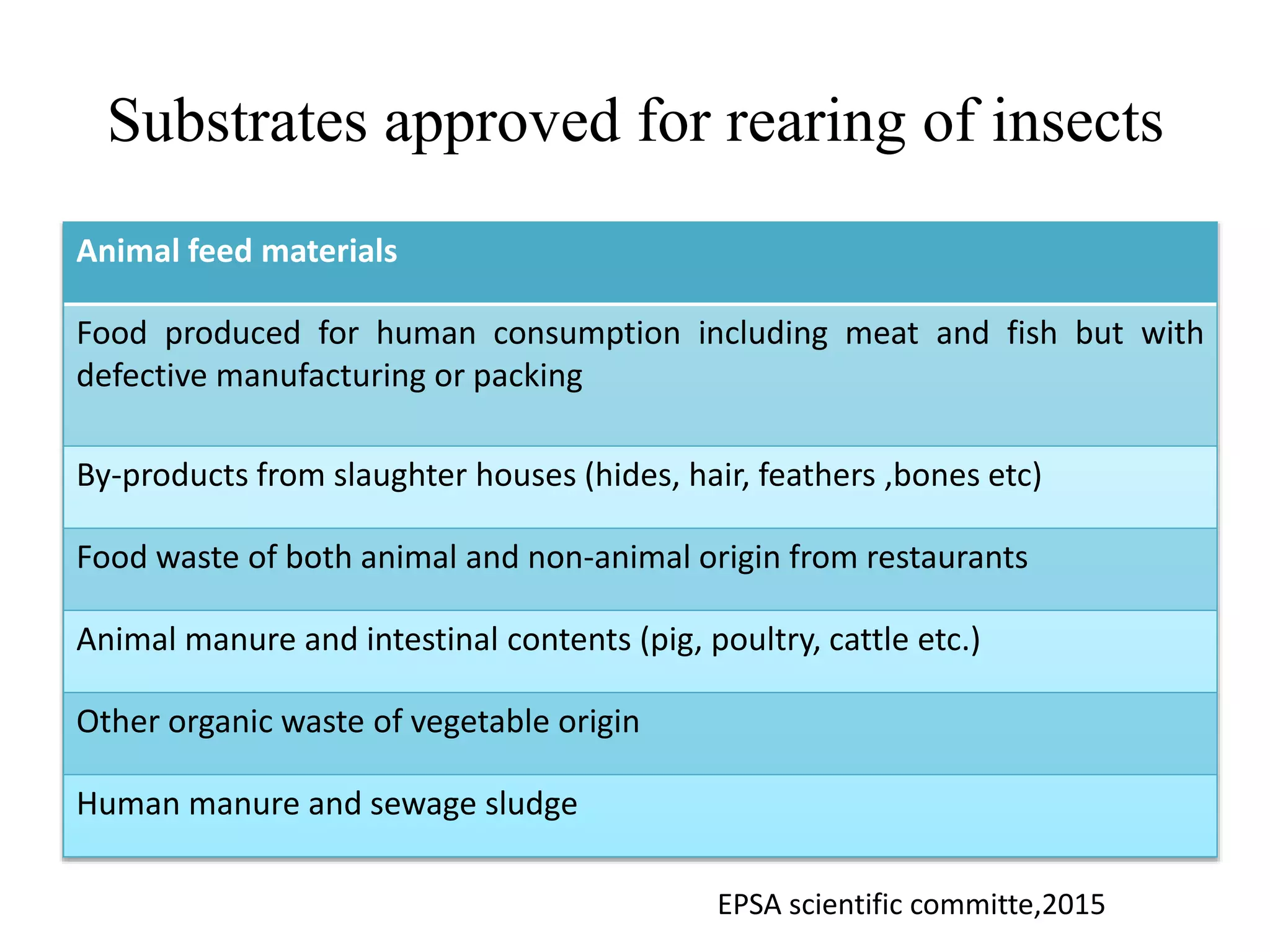

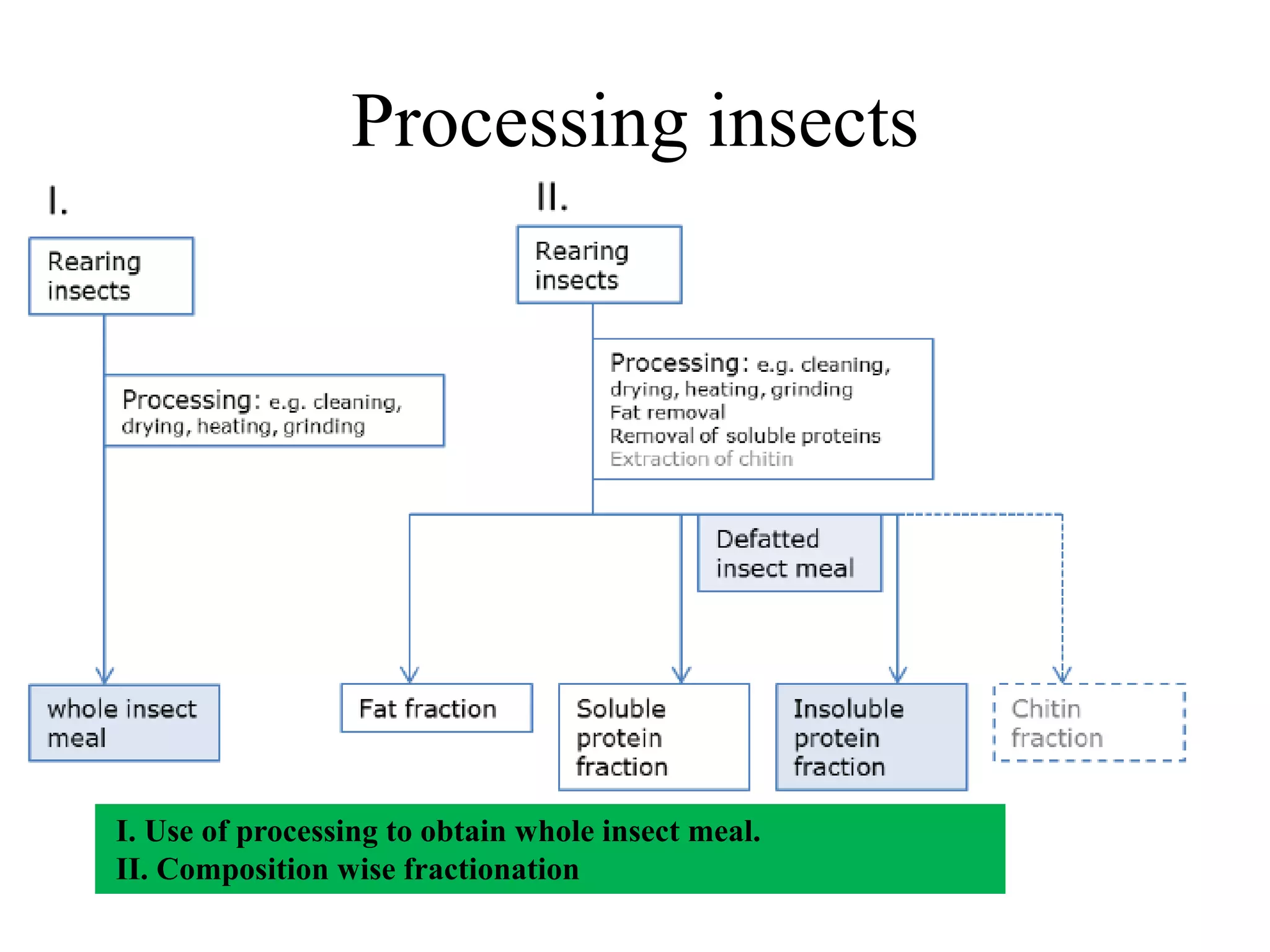

The document discusses the increasing demand for meat and eggs, particularly in developing countries, and highlights the need for alternative protein sources due to the rising costs and limited availability of traditional feeds like soybean meal and fishmeal. It presents insects as a viable and sustainable protein alternative for animal feeds, detailing their nutritional value, rearing methods, and potential to convert bio-waste into high-quality protein. The analysis concludes with recommendations for regulatory frameworks and future research to support the use of insects in poultry feed.