This document summarizes research on an inkjet-printed graphene-based flexible humidity sensor. Key points:

- Researchers from MIMOS Berhad developed a humidity sensor consisting of an interdigitated electrode made from reduced graphene oxide and silver nanoparticle ink, with graphene oxide as the sensing material, printed on a flexible polyethylene terephthalate substrate.

- The graphene oxide sensing material's dielectric constant changes with humidity, allowing the sensor to detect humidity levels based on capacitance measurements.

- Testing showed the sensor achieved a highest sensitivity of 0.15pF/%RH at 50°C, with a linear response at low humidity and exponential increase above 60%RH. It also demonstrated good temperature dependence below

![2020 IEEE International Conference on Semiconductor Electronics (ICSE)

978-1-7281-5968-3/20/$31.00 ©2020 IEEE

Inkjet-Printed Graphene-based Flexible Humidity

Sensor for Environmental Applications

Suraya Sulaiman

Nanoelectronics Lab

MIMOS Berhad

Kuala Lumpur, Malaysia

suraya.sulaiman@mimos.my

Nora’zah Abdul Rashid

Nanoelectronics Lab

MIMOS Berhad

Kuala Lumpur, Malaysia

norazah@mimos.my

Aiman Sajidah Abdul Aziz

Nanoelectronics Lab

MIMOS Berhad

Kuala Lumpur, Malaysia

aiman.sajidah@mimos.my

Liew Qiao Jun

Nanoelectronics Lab

MIMOS Berhad

Kuala Lumpur, Malaysia

qj.liew@mimos.my

Syed Muhammad Hafiz Syed Mohd Jaafar

Nanoelectronics Lab

MIMOS Berhad

Kuala Lumpur, Malaysia

hafiz.jaafar@mimos.my

Abstract—In this study, a fully flexible inkjet-printed

graphene-based capacitive humidity sensor is investigated

using graphene oxide (GO) as sensing material mixed with

Polyacrylic Acid, PAA. The printed humidity sensor consists

of i) an optimally designed interdigitated electrode (IDE)

made from reduced graphene oxide conductive ink material

decorated with silver nanoparticle (rGO/Ag), ii) inkjet-

printed GO as sensing material and iii) polyethylene

terephthalate, PET as flexible substrate. The conductive ink

is synthesize in house with a stable and consistent

temperature setting which has successfully improve the yield

performance of the graphene-based inkjet and the method of

preparation has prevent the ink from agglomeration during

printing. The multilayer inkjet-printed GO on top of the

rGO/Ag IDE is employ to increase the contact area between

the sensing layer and water vapor, thus leading to a high

sensitivity sensor. The results shows that as the relative

humidity is varies in the range of 30%RH to 90%RH, the

proposed humidity sensor is able to achieve a highest

sensitivity of 0.15pF/%RH at 50°C. The sensor show a stable

capacitance value with a linear output at low humidity and

increase exponentially at above 60%RH. The developed

sensor also show a good temperature dependence at

temperature below 60°C and humidity lower than 70%RH.

Keywords—flexible; printed; multilayer; graphene;

humidity

I. INTRODUCTION

The high demand for future electronic devices,

particularly on wearable device, seek a huge demand for

new production and manufacturing methods beyond the

traditional semiconductor cleanroom processes, which are

typically achieved at vacuum and high temperature

condition. In view of that, inkjet printing with the use of

nano-based conductive inks offers a high potential to

support the development of the next generation wearable

electronic devices due to its lower cost, low temperature,

less complex and vacuum-less process technologies.

The development of printing technology with the

formulation of a new simple, low-cost conductive ink

material will enable the production of a range of functional

sensors and electronics devices including humidity

sensors. Humidity sensors have been widely used in our

daily lives and become increasingly important in many

applications such as meteorology, agriculture, smart

homes, medical equipment, and biotechnology [1–4].

Various types of humidity sensors are available, based on

different measurement principles such as resistive,

capacitive, optical, acoustic, and thermal techniques.

Among them all, the capacitive devices are preferred due

to their high sensitivity, linearity, accuracy, fast response

time, and negligible temperature dependent. Most of these

capacitive sensors are based on the dielectric changes in

the sensing layer upon water vapour uptake as a measure

of the water vapour content in the environment.

II. SENSING PRINCIPLES

This paper propose a flexible, high-sensitivity and low-

hysteresis printed capacitive humidity sensor consists of

inkjet-printed IDE and GO as the sensing materials. This

capacitive humidity sensors utilize GO as the sensing

material which reacts to the environmental changes when

the surfaces adsorb water molecules. The change in

capacitance is directly in relation to the water

concentration or humidity in the environment. The IDE,

acting as the electrical conductor, is printed using

conductive rGO/Ag materials while the sensing material is

printed on top of the IDE to form the high-sensitivity

flexible humidity sensor as shown in Fig. 1 below. Here,

the sensor platform is equipped by inserting the inkjet-

printed sensor into a connector which is soldered to PCB

board that was attached with Harwin connector for use in

sensing test later.

Fig. 1. Samples of inkjet-printed graphene-based flexible humidity

sensor.

148

Authorized licensed use limited to: CMU Libraries - library.cmich.edu. Downloaded on August 18,2020 at 13:13:34 UTC from IEEE Xplore. Restrictions apply.](https://image.slidesharecdn.com/inkjet-printedgraphene-basedflexiblehumiditysensorforenvironmentalapplications-211207073834/75/Inkjet-printed-graphene-based-flexible-humidity-sensor-for-environmental-applications-1-2048.jpg)

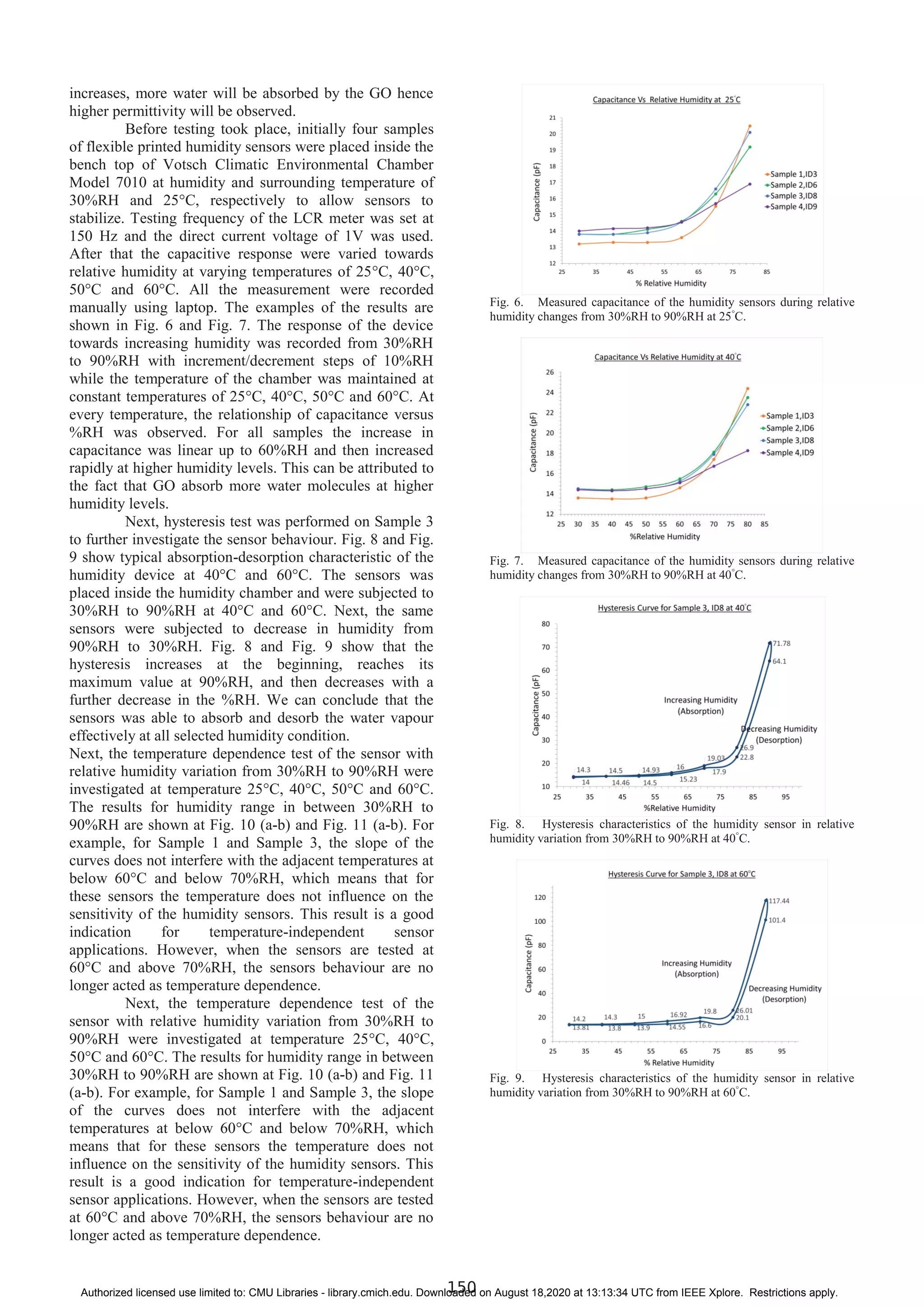

![Fig. 10 (a)

Fig. 10 (b)

Fig.10. (a) Temperature dependence of the humidity sensor measured at

below 70%RH, at 25°C, 40°C, 50°C and 60°C for Sample 1 and (b)

Temperature dependence of the humidity sensor measured at below

70%RH, at 25°C, 40°C, 50°C and 60°C for Sample 3.

Fig. 11 (a)

Fig. 11 (b)

Fig.11. (a) Temperature dependence of the humidity sensor measured

over 70%RH, at 25°C, 40°C, 50°C and 60°C for Sample 1 and (b)

Temperature dependence of the humidity sensor measured over 70%RH,

at 25°C, 40°C, 50°C and 60°C for Sample 3.

Next, the sensitivity, S of the humidity sensors can be

expressed as;

S = C90 – C30 (pF/%RH) (2)

90 – 30

where C90 and C30 denote the capacitance obtained at

90%RH and 30%RH, respectively [5]. The 90 and 30

values are the highest and lowest relative humidity values

in the variation range, respectively. Fig. 12 shows the

sensitivity of humidity sensors at different temperature

variation for all sensors. From the histogram, sample 4

can be concluded as the most sensitive sensor. The results

show that as the relative humidity ranges from 30%RH to

90%RH, the proposed humidity sensors are able to

achieve a high sensitivity of 0.15pF/%RH at 50°C.

Fig. 12. Sensitivity of humidity sensor at temperature range between

25°C to 60°C.

V. CONCLUSIONS

In summary, a fully flexible ink-jet printed graphene-

based capacitive humidity sensor is investigated and

successfully demonstrated working at certain humidity

and temperature range. The humidity-sensitive layer

composed of a GO layer is successfully printed on IDE

platform which manage to simplify the fabrication process

of a conventional humidity sensor. During actual testing,

this paper demonstrated a sensor with a high sensitivity of

0.15pF/%RH at 50°C for Sample 4 with stable

capacitance value with an exponential output ranging

from 30%RH to 90%RH. It has been shown that the

developed sensor is also independent of temperature

change at temperature less than 60°C and humidity level

below 70%RH. More process optimization and

investigation need to be carried out later to improve the

sensor performance which include sensing thickness

optimization and optimum printing quality.

REFERENCES

[1] Chen, Z.; Lu, C. Humidity sensors: a review08p of materials and

mechanisms. Sensor Lett. 2005, 3, 274–295.[CrossRef]

[2] Lee, C.W.; Lee, S.J.; Kim, M.; Kyung, Y.; Eom, K. Capacitive

humidity sensor tag smart refrigerator system using the capacitive to

voltage converter. Int. J. Adv. Sci. Technol. 2011, 36, 15–25.

[3] Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity sensors

principle, mechanism, and fabrication technologies: a comprehensive

review. Sensors 2014, 14, 7881–7939. [CrossRef]

[4] Feng, Y.; Xie, L.; Chen, Q.; Zheng, L.R. Low-cost printed chipless

RFID humidity sensor tag for intelligent packaging. IEEE Sens. J. 2015,

15, 3201–3208. [CrossRef]

[5] Liu, M.Q; Wang, C.; Kim N.Y.; High-Sensitivity and Low-

Hysteresis Porous MIM-Type Capacitive Hum idity Sensor Using

Functional Polymer Mixed with TiO2 Microparticles. Sensors 2017, 17,

284, 1-11.

151

Authorized licensed use limited to: CMU Libraries - library.cmich.edu. Downloaded on August 18,2020 at 13:13:34 UTC from IEEE Xplore. Restrictions apply.](https://image.slidesharecdn.com/inkjet-printedgraphene-basedflexiblehumiditysensorforenvironmentalapplications-211207073834/75/Inkjet-printed-graphene-based-flexible-humidity-sensor-for-environmental-applications-4-2048.jpg)