This document summarizes a study on graphene-based polyelectrolyte coatings for flexible substrates. The researchers prepared silane-functionalized graphene (f-G) incorporated with polyanion polystyrene sulfonate (PSS) and coated it on an amorphous polyethylene terephthalate (APET) substrate with a polycation polydiallyldimethyl ammonium chloride (PDDA) top layer. They characterized the morphological, optical and mechanical properties of coatings with 0.01 wt.% f-G/PSS, finding it had high optical transparency of 90.9% and low haze of 7.0%, as well as good adhesion strength. The coating thickness was 159-240

![Graphene-based Polyelectrolytes Coating Assembly: Study on

Morphological, Optical and Mechanical Properties

Syed Muhammad Hafiz1

*, Norhaizam Mustaffa1

, Nora’zah Abdul Rashid1

, Aiman

Sajidah Abd Aziz1

, Suraya Sulaiman1

1

Flexible Electronics Laboratory, Research and Development, MIMOS Berhad,

Technology Park Malaysia, Kuala Lumpur, Malaysia

*Corresponding author’s phone: +603-8995 5000

E-mail: hafiz.jaafar@mimos.my

ABSTRACT

The structural practicality for real-

world application of polyelectrolytes

antibacterial coating has not been widely

studied yet despite having a huge potential.

Therefore, this may possess a huge

hindrance when the commercialization

stage takes place. In this study, various

loading of silane functionalized-graphene

(f-G) which then incorporated with

polyanion, i.e. polystyrene sulfonate

(PSS), was coated on a flexible amorphous

polyethylene terephthalate (APET)

substrate with polycation, i.e.

polydiallyldimethyl ammonium chloride

(PDDA) on top of it. The morphological,

optical and mechanical properties were

demonstrated for a coating assembly of

0.01 wt.% f-G/PSS that have high optical

transparency (90.9%) with low haze

(7.0%) as well as good adhesion according

toASTM D3359 (scaled at 5B) standard.

Keywords— polyelectrolyte assembly;

graphene; transparent coating; flexible

coating; antibacterial coating.

1.0 INTRODUCTION

With the ongoing worldwide

pandemic of coronavirus disease since late

2019 (COVID-19), the study on

antibacterial coating has been significantly

increased. In addition, water borne

microorganisms like undesirable bacteria

pose a significant risk to public health.

Pathogenic variants of Escherichia coliare

(E. Coli), for example, is one of the causes

of worldwide morbidity and mortality [1].

Several polyelectrolytes polymers (e.g.

PDDA and PSS) exhibit a useful

antimicrobial property has been discussed.

However, most studies inclined with the

relationship between structure-activity,

which still left a gap for a complete

investigation in terms ofthe relationship

between structure-practicality for real-

world application for example in terms of

adhesion and haze or optical transmission

[2].

2.0 THEORY

The mechanism of antibacterial

properties of polyelectrolytes might be

following several sequences of events

occurs with microorganisms exposed to

cationic or anionic agents, starting with;

(i) adsorption and penetration of the agent

into the cell wall; (ii) reaction with the

cytoplasmic membrane followed by

membrane disorganization; (iii) leakage

of intracellular low-molecular-weight

material; (iv) degradation of proteins and

nucleic acids; and finally (v) wall lysis

caused by autolytic enzymes. There would

be a loss of structural organization and

integrity of the cytoplasmic membrane in

bacteria, together with other damaging

effects to the bacterial cell [2].

3.0 MATERIALS

Amorphous polyethylene

terephthalate (APET) substrate was

supplied from Macro Plastic (M) Sdn.

Proceedings of the 4th International Symposium on Advanced Materials and Nanotechnology 2020

(i-SAMN2020), December 1-3, 2020

eISBN 978-983-42758-7-7 ©2020 ITMA, UPM 118](https://image.slidesharecdn.com/graphene-basedpolyelectrolytescoatingassembly-studyonmorphologicalopticalandmechanicalproperties-211207073218/75/Graphene-based-polyelectrolytes-coating-assembly-study-on-morphological-optical-and-mechanical-properties-1-2048.jpg)

![Bhd. Poly (sodium4-styrenesulfonate)

solution (PSS) Mw ~200,000 and Poly

(diallyldimethyl ammonium chloride)

solution (PDDA) Mw ~200,000-350,000,

both with 2 wt.% in H2O was purchased

from Sigma-Aldrich. Graphene

nanoplatelets, xGnP® with 5µm flake size

was purchase from XG Sciences Inc.

Silane coupling agent, (3-Aminopropyl)

triethoxysilane (APTES) ≥98%, was

purchased from Sigma-Aldrich.

4.0 EXPERIMENTAL

4.1 Preparation of f-G/PSS solution

For the preparation of silane

functionalized graphene, it was carried out

in water/ethanol mixture according to

reference [3]. In brief, xGnP® powder was

added into water/ethanol mixture under

mild sonication for 1 hour at 1 mg/mL

concentration. Then, APTES was added

into the mixture drop wise with 10 v/v% at

65 °C, and the reaction was continued to

process for 12 h under constant stirring.

Subsequently, the final reactant was

washed with methanol and filtered several

times. The products, (3-Aminopropyl)

triethoxysilane-xGnP, abbreviated as f-G

throughout this paper will then undergo

drying process in an oven at 60 °C for 12

h. Finally, the 0.1, 0.05 and 0.01 wt.% of f-

G powder was prepared by mixing with

polyanion PSS of 2 wt.% solution and

sonicated for 4 hours until homogeneous

mixture achieved. Figure 1(a) shows the

image of the as-prepared f-G/PSS final

solution.

Fig. 1: The as-prepared f-G/PSS (a) solution and

(b-c) coated on APET/PDDA substrate.

4.2 Preparation technique of

graphene-based polyelectrolyte

assembly coating

APET substrate was cut into 5 cm

x 5 cm size and then cleaned with 5 wt.%

NaOH followed with deionized water and

finally dip-coated with PDDA for 2

minutes. The substrate is now will be

referred as APET/PDDA. Next, the as-

prepared f-G/PSS solution was spray-

coated with 150 µL solution on

APET/PDDA substrate and left it dry

overnight at room temperature. Figure 1(b)

and (c) show the f-G/PSS coating which is

highly transparent and flexible.

4.3 Characterization

The morphology of coated samples

was characterized by a field emission

scanning electron microscopy (FESEM),

Hitachi SU8030. The images were

recorded at an accelerating voltage of 5kV.

X-ray energy dispersive spectroscopy

(EDS) was used to examine the chemical

composition on the surface of the coated

samples. The optical properties; haze and

transmittance of the coated samples were

determined by Haze & Reflectance Meter

HR-100, Murakami Color Research

Laboratory. The adhesion test, according

to ASTM D3359 standard was carried out

using 3MTM

#600 scotch tape to determine

the adhesion strength of the coated

samples.

5.0 RESULTS AND DISCUSSION

5.1 Morphological Properties

A typical optical image (top view,

10x objective) and FESEM micrograph

(cross-section view, 5k magnification) of

f-G/PSS coated morphology was shown in

Figure 2(a-b). The FESEM cross section

micrographs shows each assembly layer

for the f-G/PSS coated on APET/PDDA

substrate. The thickness of f-G/PSS is

around 159 to 240 nm while the thickness

of PDDA coated layer is 2.14 µm.

Bhd. Poly (sodium4-styrenesulfonate)

solution (PSS) Mw ~200,000 and Poly

(diallyldimethyl ammonium chloride)

solution (PDDA) Mw ~200,000-350,000,

both with 2 wt.% in H2O was purchased

from Sigma-Aldrich. Graphene

nanoplatelets, xGnP® with 5µm flake size

was purchase from XG Sciences Inc.

Silane coupling agent, (3-Aminopropyl)

triethoxysilane (APTES) ≥98%, was

purchased from Sigma-Aldrich.

4.0 EXPERIMENTAL

4.1 Preparation of f-G/PSS solution

For the preparation of silane

functionalized graphene, it was carried out

in water/ethanol mixture according to

reference [3]. In brief, xGnP® powder was

added into water/ethanol mixture under

mild sonication for 1 hour at 1 mg/mL

concentration. Then, APTES was added

into the mixture drop wise with 10 v/v% at

65 °C, and the reaction was continued to

process for 12 h under constant stirring.

Subsequently, the final reactant was

washed with methanol and filtered several

times. The products, (3-Aminopropyl)

triethoxysilane-xGnP, abbreviated as f-G

throughout this paper will then undergo

drying process in an oven at 60 °C for 12

h. Finally, the 0.1, 0.05 and 0.01 wt.% of f-

G powder was prepared by mixing with

polyanion PSS of 2 wt.% solution and

sonicated for 4 hours until homogeneous

mixture achieved. Figure 1(a) shows the

image of the as-prepared f-G/PSS final

solution.

Fig. 1: The as-prepared f-G/PSS (a) solution and

(b-c) coated on APET/PDDA substrate.

4.2 Preparation technique of

graphene-based polyelectrolyte

assembly coating

APET substrate was cut into 5 cm

x 5 cm size and then cleaned with 5 wt.%

NaOH followed with deionized water and

finally dip-coated with PDDA for 2

minutes. The substrate is now will be

referred as APET/PDDA. Next, the as-

prepared f-G/PSS solution was spray-

coated with 150 µL solution on

APET/PDDA substrate and left it dry

overnight at room temperature. Figure 1(b)

and (c) show the f-G/PSS coating which is

highly transparent and flexible.

4.3 Characterization

The morphology of coated samples

was characterized by a field emission

scanning electron microscopy (FESEM),

Hitachi SU8030. The images were

recorded at an accelerating voltage of 5kV.

X-ray energy dispersive spectroscopy

(EDS) was used to examine the chemical

composition on the surface of the coated

samples. The optical properties; haze and

transmittance of the coated samples were

determined by Haze & Reflectance Meter

HR-100, Murakami Color Research

Laboratory. The adhesion test, according

to ASTM D3359 standard was carried out

using 3MTM

#600 scotch tape to determine

the adhesion strength of the coated

samples.

5.0 RESULTS AND DISCUSSION

5.1 Morphological Properties

A typical optical image (top view,

10x objective) and FESEM micrograph

(cross-section view, 5k magnification) of

f-G/PSS coated morphology was shown in

Figure 2(a-b). The FESEM cross section

micrographs shows each assembly layer

for the f-G/PSS coated on APET/PDDA

substrate. The thickness of f-G/PSS is

around 159 to 240 nm while the thickness

of PDDA coated layer is 2.14 µm.

Bhd. Poly (sodium4-styrenesulfonate)

solution (PSS) Mw ~200,000 and Poly

(diallyldimethyl ammonium chloride)

solution (PDDA) Mw ~200,000-350,000,

both with 2 wt.% in H2O was purchased

from Sigma-Aldrich. Graphene

nanoplatelets, xGnP® with 5µm flake size

was purchase from XG Sciences Inc.

Silane coupling agent, (3-Aminopropyl)

triethoxysilane (APTES) ≥98%, was

purchased from Sigma-Aldrich.

4.0 EXPERIMENTAL

4.1 Preparation of f-G/PSS solution

For the preparation of silane

functionalized graphene, it was carried out

in water/ethanol mixture according to

reference [3]. In brief, xGnP® powder was

added into water/ethanol mixture under

mild sonication for 1 hour at 1 mg/mL

concentration. Then, APTES was added

into the mixture drop wise with 10 v/v% at

65 °C, and the reaction was continued to

process for 12 h under constant stirring.

Subsequently, the final reactant was

washed with methanol and filtered several

times. The products, (3-Aminopropyl)

triethoxysilane-xGnP, abbreviated as f-G

throughout this paper will then undergo

drying process in an oven at 60 °C for 12

h. Finally, the 0.1, 0.05 and 0.01 wt.% of f-

G powder was prepared by mixing with

polyanion PSS of 2 wt.% solution and

sonicated for 4 hours until homogeneous

mixture achieved. Figure 1(a) shows the

image of the as-prepared f-G/PSS final

solution.

Fig. 1: The as-prepared f-G/PSS (a) solution and

(b-c) coated on APET/PDDA substrate.

4.2 Preparation technique of

graphene-based polyelectrolyte

assembly coating

APET substrate was cut into 5 cm

x 5 cm size and then cleaned with 5 wt.%

NaOH followed with deionized water and

finally dip-coated with PDDA for 2

minutes. The substrate is now will be

referred as APET/PDDA. Next, the as-

prepared f-G/PSS solution was spray-

coated with 150 µL solution on

APET/PDDA substrate and left it dry

overnight at room temperature. Figure 1(b)

and (c) show the f-G/PSS coating which is

highly transparent and flexible.

4.3 Characterization

The morphology of coated samples

was characterized by a field emission

scanning electron microscopy (FESEM),

Hitachi SU8030. The images were

recorded at an accelerating voltage of 5kV.

X-ray energy dispersive spectroscopy

(EDS) was used to examine the chemical

composition on the surface of the coated

samples. The optical properties; haze and

transmittance of the coated samples were

determined by Haze & Reflectance Meter

HR-100, Murakami Color Research

Laboratory. The adhesion test, according

to ASTM D3359 standard was carried out

using 3MTM

#600 scotch tape to determine

the adhesion strength of the coated

samples.

5.0 RESULTS AND DISCUSSION

5.1 Morphological Properties

A typical optical image (top view,

10x objective) and FESEM micrograph

(cross-section view, 5k magnification) of

f-G/PSS coated morphology was shown in

Figure 2(a-b). The FESEM cross section

micrographs shows each assembly layer

for the f-G/PSS coated on APET/PDDA

substrate. The thickness of f-G/PSS is

around 159 to 240 nm while the thickness

of PDDA coated layer is 2.14 µm.

119](https://image.slidesharecdn.com/graphene-basedpolyelectrolytescoatingassembly-studyonmorphologicalopticalandmechanicalproperties-211207073218/75/Graphene-based-polyelectrolytes-coating-assembly-study-on-morphological-optical-and-mechanical-properties-2-2048.jpg)

![Fig. 2: Optical image and cross-section FESEM

micrograph of f-G/PSS coating morphology (a) and

(b). EDS spectra of corresponding coating layers of

the assembly starting from the top(c) f-G/PSS, (d)

PDDA, and (e) APET substrate.

The chemical composition for each

layer, Figure 2(c-e) was further evaluated

by EDS spectrum and the first layer

composed of C, Si and S correlates well

with f-G/PSS layer whereas the second

layer composed of N referred to PDDA

and the third layer composed of C and O,

the APET substrate. A close contact

between each layer shown in the cross-

section image indicates a good wettability

of the f-G/PSS solution when spray-coated

on top of APET/PDDA substrate.

5.2 Optical Properties

The haze and transmittance of 0.1,

0.05, and 0.01 wt.% of f-G/PSS coatings

were recorded in Table I with the haze was

measured to be at 20.4, 11.3, and 7.0 %,

respectively. The haze increase with the

increase of f-G wt.% loading.

The transmittance of 0.1, 0.05, and 0.01

wt.% f-G/PDDA coatings was measured at

66.5, 80.2, and 90.9 %, respectively. The

low haze and higher transmittance give out

the best transparency of the coating which

is comparable with recent work from Ren

et. al. and with 90% transparency,

respectively [4]. Therefore, in this work,

the 0.01 wt.% f-G/PDDA coating

portrayed the lowest haze and the highest

transmittance, making it suitable for

transparent antibacterial coating

applications.

TABLE I: Summary of Haze and

Transmittance of substrate with various

coating assembly.

Sample name

Haze

(%)

Transmittance

(%)

APET 2.2 92.5

APET/PDDA 2.6 92.4

0.1 wt.%

f-G/PSS

20.4 66.5

0.05 wt.%

f-G/PSS

11.3 80.2

0.01 wt.%

f-G/PSS

7.0 90.9

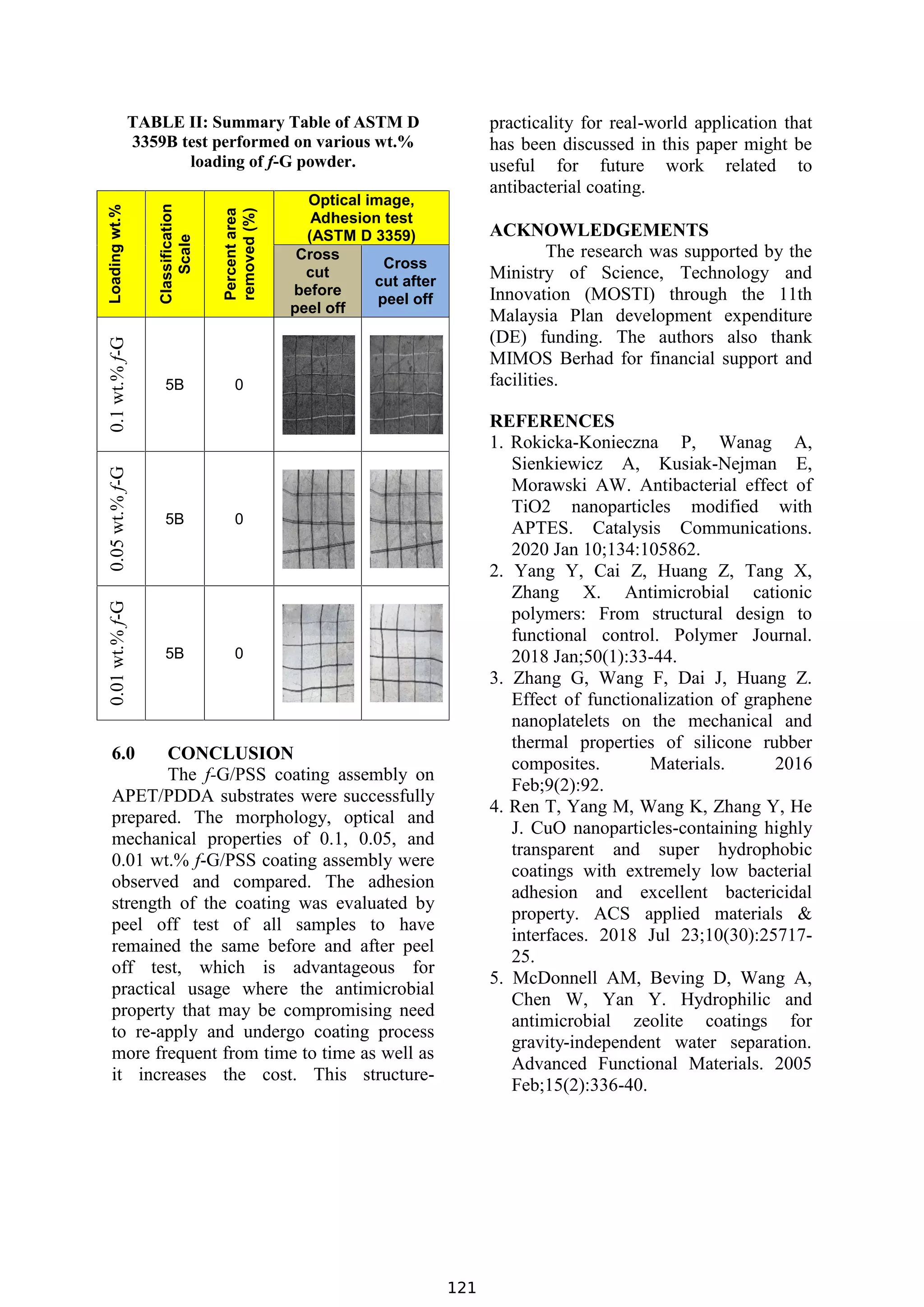

5.3 Mechanical Property

To analyze the adhesion strength of

the coating, Table II represents the result

of another adhesion test according to

ASTM D3359 which assessed on a 0B to

5B scale; 0B, >65%; 1B, 35-65%; 2B, 15-

35%; 3B, 5-15%; 4B <5% and 5B, 0%

area removed, respectively. All the

samples pass the tape adhesion test with a

classification of 5B with 0% area removed

after the test. It can be concluded that

despite the different wt.% loading of f-G

was used, all the samples have strong

adhesion towards the substrate which

correlates well with the FESEM cross-

section image. Despite simple coating

process, it is comparable to the complex

process found in the literature [5].

If the wt.% loading of f-G is below 0.01

wt.% or only PSS was used, it will not

retain a good adhesion anymore which

confirms that f-G plays an important role

in an excellent coating assembly.

Fig. 2: Optical image and cross-section FESEM

micrograph of f-G/PSS coating morphology (a) and

(b). EDS spectra of corresponding coating layers of

the assembly starting from the top(c) f-G/PSS, (d)

PDDA, and (e) APET substrate.

The chemical composition for each

layer, Figure 2(c-e) was further evaluated

by EDS spectrum and the first layer

composed of C, Si and S correlates well

with f-G/PSS layer whereas the second

layer composed of N referred to PDDA

and the third layer composed of C and O,

the APET substrate. A close contact

between each layer shown in the cross-

section image indicates a good wettability

of the f-G/PSS solution when spray-coated

on top of APET/PDDA substrate.

5.2 Optical Properties

The haze and transmittance of 0.1,

0.05, and 0.01 wt.% of f-G/PSS coatings

were recorded in Table I with the haze was

measured to be at 20.4, 11.3, and 7.0 %,

respectively. The haze increase with the

increase of f-G wt.% loading.

The transmittance of 0.1, 0.05, and 0.01

wt.% f-G/PDDA coatings was measured at

66.5, 80.2, and 90.9 %, respectively. The

low haze and higher transmittance give out

the best transparency of the coating which

is comparable with recent work from Ren

et. al. and with 90% transparency,

respectively [4]. Therefore, in this work,

the 0.01 wt.% f-G/PDDA coating

portrayed the lowest haze and the highest

transmittance, making it suitable for

transparent antibacterial coating

applications.

TABLE I: Summary of Haze and

Transmittance of substrate with various

coating assembly.

Sample name

Haze

(%)

Transmittance

(%)

APET 2.2 92.5

APET/PDDA 2.6 92.4

0.1 wt.%

f-G/PSS

20.4 66.5

0.05 wt.%

f-G/PSS

11.3 80.2

0.01 wt.%

f-G/PSS

7.0 90.9

5.3 Mechanical Property

To analyze the adhesion strength of

the coating, Table II represents the result

of another adhesion test according to

ASTM D3359 which assessed on a 0B to

5B scale; 0B, >65%; 1B, 35-65%; 2B, 15-

35%; 3B, 5-15%; 4B <5% and 5B, 0%

area removed, respectively. All the

samples pass the tape adhesion test with a

classification of 5B with 0% area removed

after the test. It can be concluded that

despite the different wt.% loading of f-G

was used, all the samples have strong

adhesion towards the substrate which

correlates well with the FESEM cross-

section image. Despite simple coating

process, it is comparable to the complex

process found in the literature [5].

If the wt.% loading of f-G is below 0.01

wt.% or only PSS was used, it will not

retain a good adhesion anymore which

confirms that f-G plays an important role

in an excellent coating assembly.

Fig. 2: Optical image and cross-section FESEM

micrograph of f-G/PSS coating morphology (a) and

(b). EDS spectra of corresponding coating layers of

the assembly starting from the top(c) f-G/PSS, (d)

PDDA, and (e) APET substrate.

The chemical composition for each

layer, Figure 2(c-e) was further evaluated

by EDS spectrum and the first layer

composed of C, Si and S correlates well

with f-G/PSS layer whereas the second

layer composed of N referred to PDDA

and the third layer composed of C and O,

the APET substrate. A close contact

between each layer shown in the cross-

section image indicates a good wettability

of the f-G/PSS solution when spray-coated

on top of APET/PDDA substrate.

5.2 Optical Properties

The haze and transmittance of 0.1,

0.05, and 0.01 wt.% of f-G/PSS coatings

were recorded in Table I with the haze was

measured to be at 20.4, 11.3, and 7.0 %,

respectively. The haze increase with the

increase of f-G wt.% loading.

The transmittance of 0.1, 0.05, and 0.01

wt.% f-G/PDDA coatings was measured at

66.5, 80.2, and 90.9 %, respectively. The

low haze and higher transmittance give out

the best transparency of the coating which

is comparable with recent work from Ren

et. al. and with 90% transparency,

respectively [4]. Therefore, in this work,

the 0.01 wt.% f-G/PDDA coating

portrayed the lowest haze and the highest

transmittance, making it suitable for

transparent antibacterial coating

applications.

TABLE I: Summary of Haze and

Transmittance of substrate with various

coating assembly.

Sample name

Haze

(%)

Transmittance

(%)

APET 2.2 92.5

APET/PDDA 2.6 92.4

0.1 wt.%

f-G/PSS

20.4 66.5

0.05 wt.%

f-G/PSS

11.3 80.2

0.01 wt.%

f-G/PSS

7.0 90.9

5.3 Mechanical Property

To analyze the adhesion strength of

the coating, Table II represents the result

of another adhesion test according to

ASTM D3359 which assessed on a 0B to

5B scale; 0B, >65%; 1B, 35-65%; 2B, 15-

35%; 3B, 5-15%; 4B <5% and 5B, 0%

area removed, respectively. All the

samples pass the tape adhesion test with a

classification of 5B with 0% area removed

after the test. It can be concluded that

despite the different wt.% loading of f-G

was used, all the samples have strong

adhesion towards the substrate which

correlates well with the FESEM cross-

section image. Despite simple coating

process, it is comparable to the complex

process found in the literature [5].

If the wt.% loading of f-G is below 0.01

wt.% or only PSS was used, it will not

retain a good adhesion anymore which

confirms that f-G plays an important role

in an excellent coating assembly.

120](https://image.slidesharecdn.com/graphene-basedpolyelectrolytescoatingassembly-studyonmorphologicalopticalandmechanicalproperties-211207073218/75/Graphene-based-polyelectrolytes-coating-assembly-study-on-morphological-optical-and-mechanical-properties-3-2048.jpg)