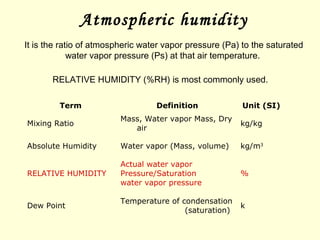

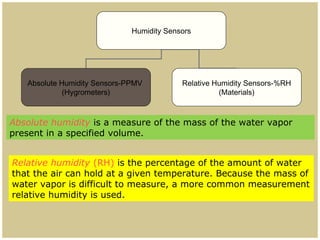

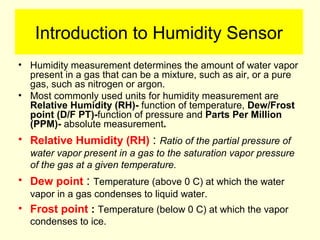

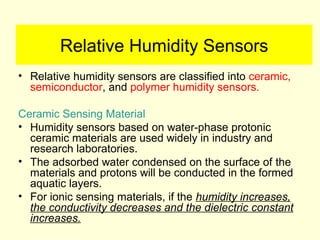

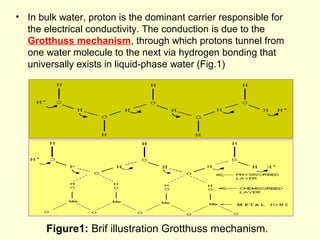

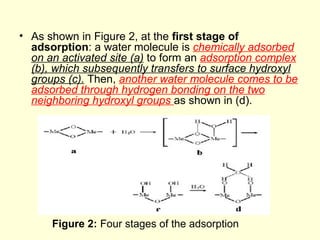

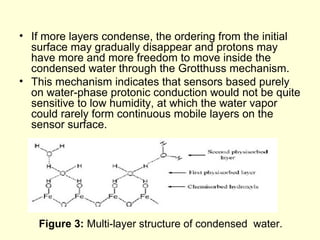

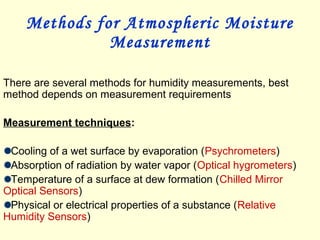

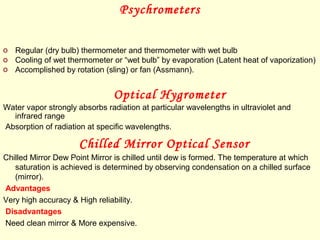

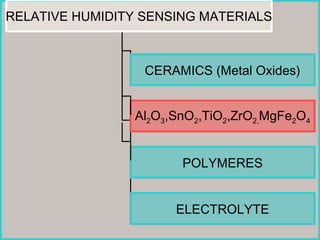

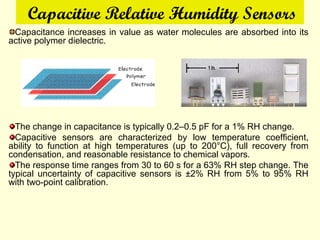

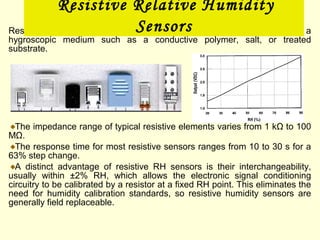

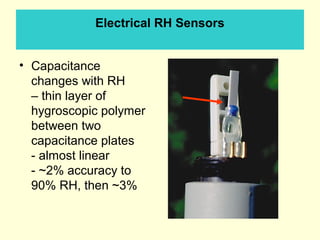

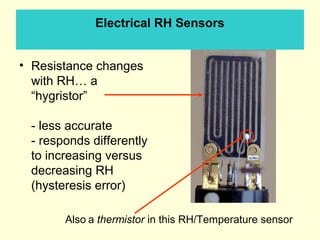

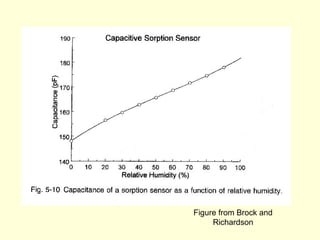

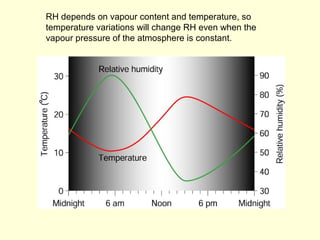

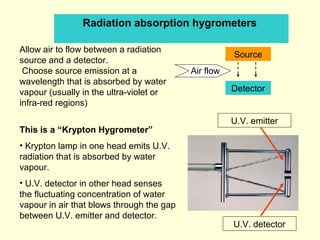

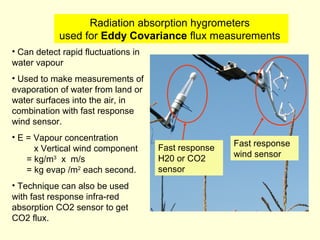

Relative humidity sensors are commonly used to measure atmospheric humidity. They work by measuring the ratio of actual water vapor pressure to the saturation vapor pressure at a given temperature. Ceramic, semiconductor, and polymer materials are often used as the sensing elements in relative humidity sensors. Ceramic sensors typically function through the Grotthuss mechanism, where adsorbed water layers allow protons to tunnel between water molecules. Capacitive and resistive relative humidity sensors also exist, where the capacitance or resistance of a hygroscopic material changes with varying humidity levels. Other humidity measurement techniques include psychrometers, chilled mirror optical sensors, and radiation absorption hygrometers. Humidity sensors have applications in fields like industrial processes, agriculture, weather monitoring