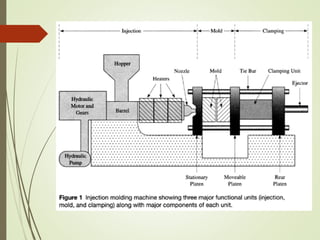

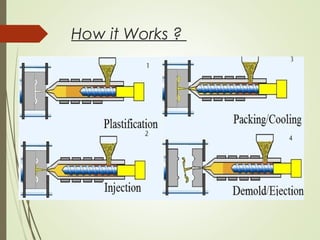

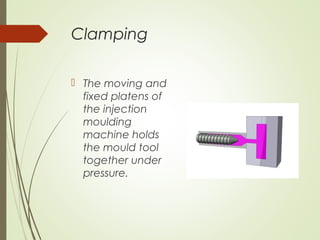

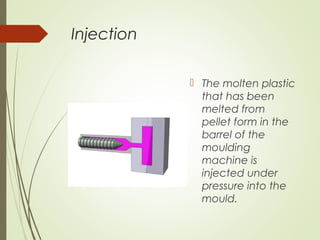

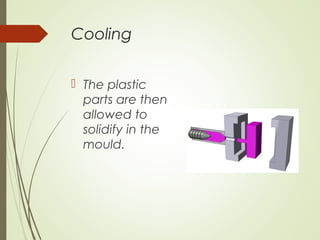

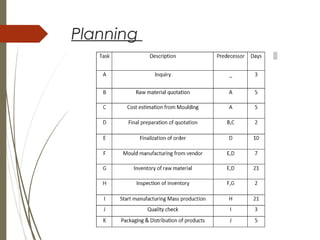

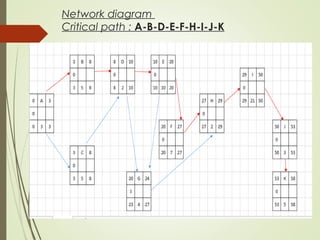

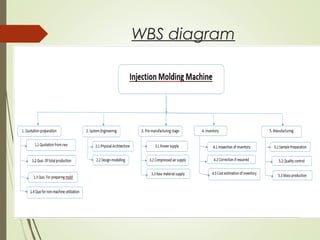

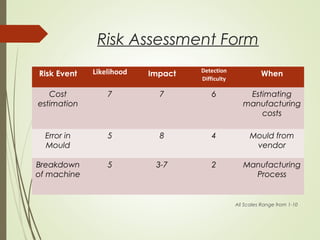

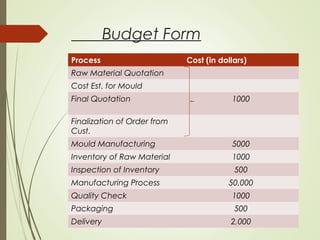

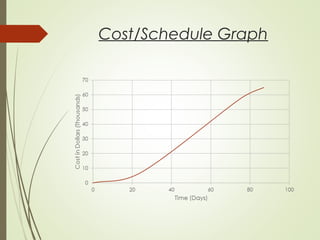

This document discusses injection moulding machines. It explains that injection moulding machines consist of an injection unit and clamping unit. It describes the injection moulding process in four steps: clamping, injection, cooling, and demoulding/ejection. The document also includes sections on planning, risk assessment, budgeting, and references.