Embed presentation

Downloaded 91 times

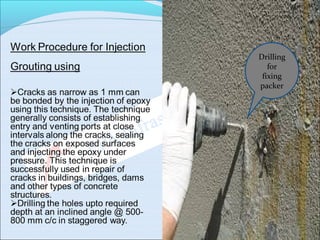

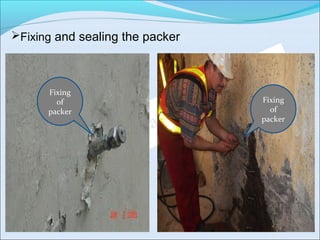

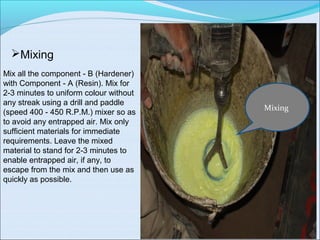

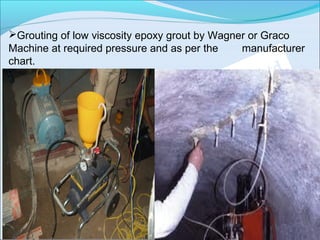

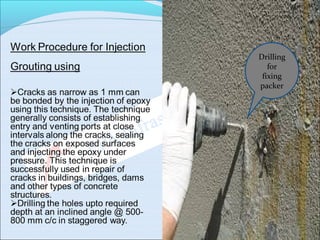

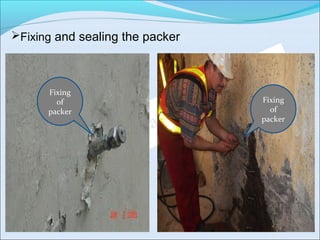

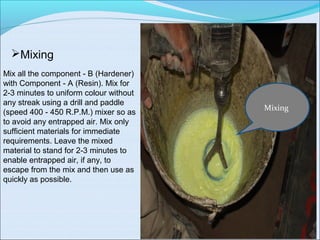

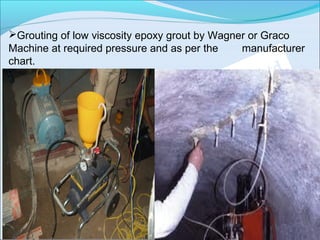

This document provides information about a low viscosity, hydro-swilling, thermosetting resin for crack injection. It lists the company contact information and provides instructions for mixing the resin components, grouting with injection equipment, and pre-processing including cleaning the area and fixing injection nipples before crack treatment.