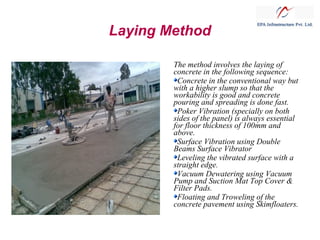

Vacuum Dewatered Flooring (VDF) is a concrete flooring method that uses vacuum dewatering to remove excess water from freshly placed concrete, lowering the water-cement ratio and improving the concrete's properties. The concrete is placed conventionally, then vibrated and leveled before a vacuum pump and suction mat remove 15-25% of the water. This increases compressive strength and reduces shrinkage and cracking. Advantages of VDF include monolithic, shrinkage-free floors in large panels up to 100 sqm, very high strength, controlled finishes, and high daily output.